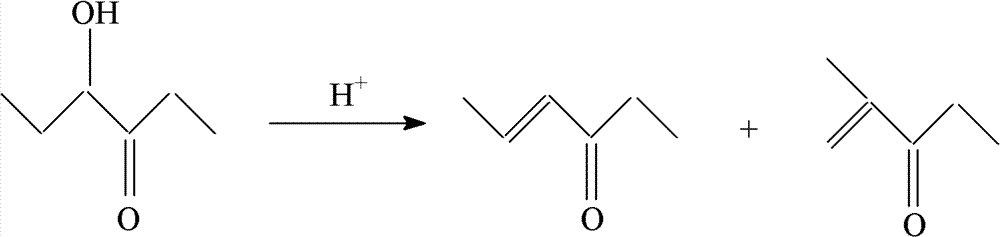

Method of catalytic dehydration by 4-hydroxyl-3-hexanone

A technology of catalytic dehydration and hydroxyl, applied in chemical instruments and methods, molecular sieve catalysts, preparation of carbon-based compounds, etc., can solve the problems of high reaction temperature, poor catalyst activity, low space velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

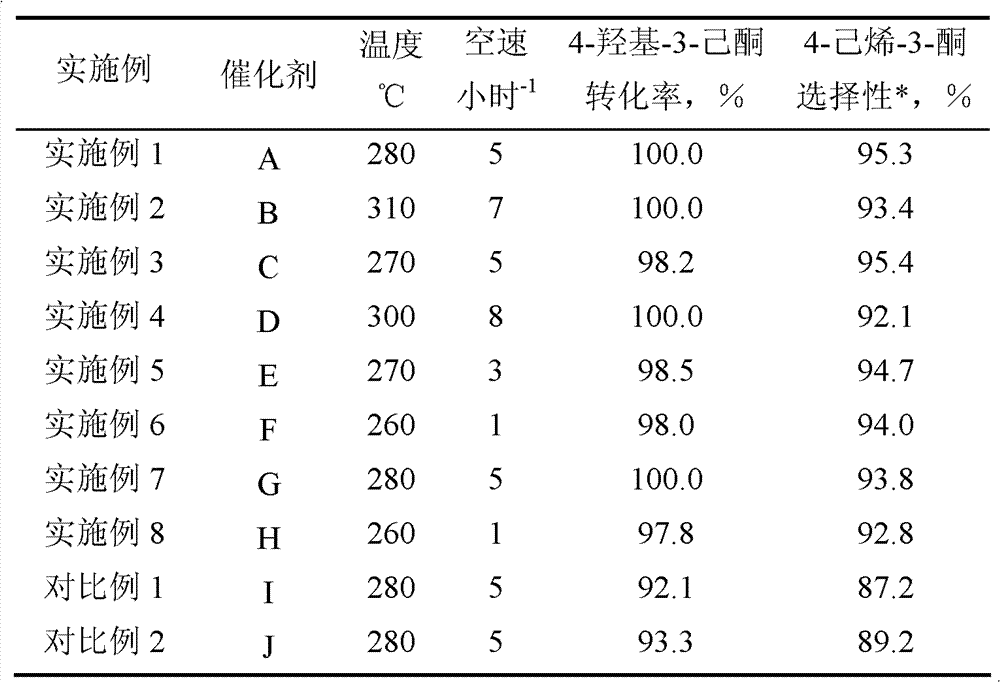

Embodiment 1

[0014] Mix 40% silica sol, sodium metaaluminate, tetrabutylammonium bromide, sodium chloride, sodium hydroxide and water, stir for 20 minutes, put into a reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain ZSM-11 molecular sieve raw powder with a grain diameter of 0.5 microns. The molar ratio of each raw material in the reaction mixture is: SiO 2 / Al 2 o 3 =145,H 2 O / SiO 2 =32.8, NaCl / SiO 2 =0.6, NaOH / SiO 2 = 0.08, TBABr / SiO 2 = 0.12.

[0015] Get 50 gram grain diameters and be the ZSM-11 molecular sieve (SiO 2 / Al 2 o 3 =145), put into 250 gram concentration and be in the aqueous sodium hydroxide solution of 0.5 mol / liter, stir at 80 ℃ of constant temperature for 0.5 hour under reflux, filter, wash with distilled water, then use the ammonium nitrate aqueous solution of 10% mass concentration at 80 Exchanged three times at ℃, the we...

Embodiment 2

[0018] Get 50 grams of grain diameter and be the ZSM-11 molecular sieve (SiO 2 / Al 2 o 3 =40), put into 100 gram concentration and be in the sodium hydroxide aqueous solution of 1 mol / liter, stir 3 hours at 60 ℃ of constant temperatures under reflux, filter, wash with distilled water, exchange, dry, roast with [Example 1] ammonium , molding, and the obtained sample is marked as B.

[0019] Press each step of [embodiment 1] and condition to evaluate the performance of catalyst, and reaction condition and reaction result are shown in Table 1.

Embodiment 3

[0021] Get 50 grams of ZSM-11 molecular sieves (SiO 2 / Al 2 o 3 =100), put into 500 grams of concentration and be 0.2 mol / liter of potassium hydroxide aqueous solution, stir at 50 ℃ of constant temperature for 3.5 hours under reflux, filter, wash with distilled water, exchange, dry, roast with [Example 1] ammonium , forming, and the obtained sample is marked as C.

[0022] Press each step of [embodiment 1] and condition to evaluate the performance of catalyst, and reaction condition and reaction result are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com