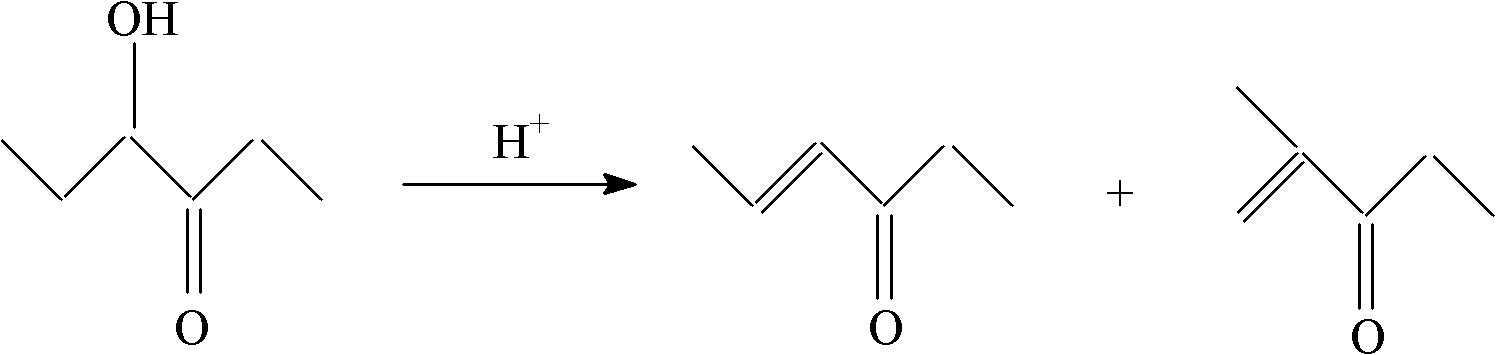

Method of 4-hydroxy-3-hexanone catalysis and dehydration

A technology for catalytic dehydration and hexanone, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc. Effects of reaction temperature, acid-enhancing amount and acid strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

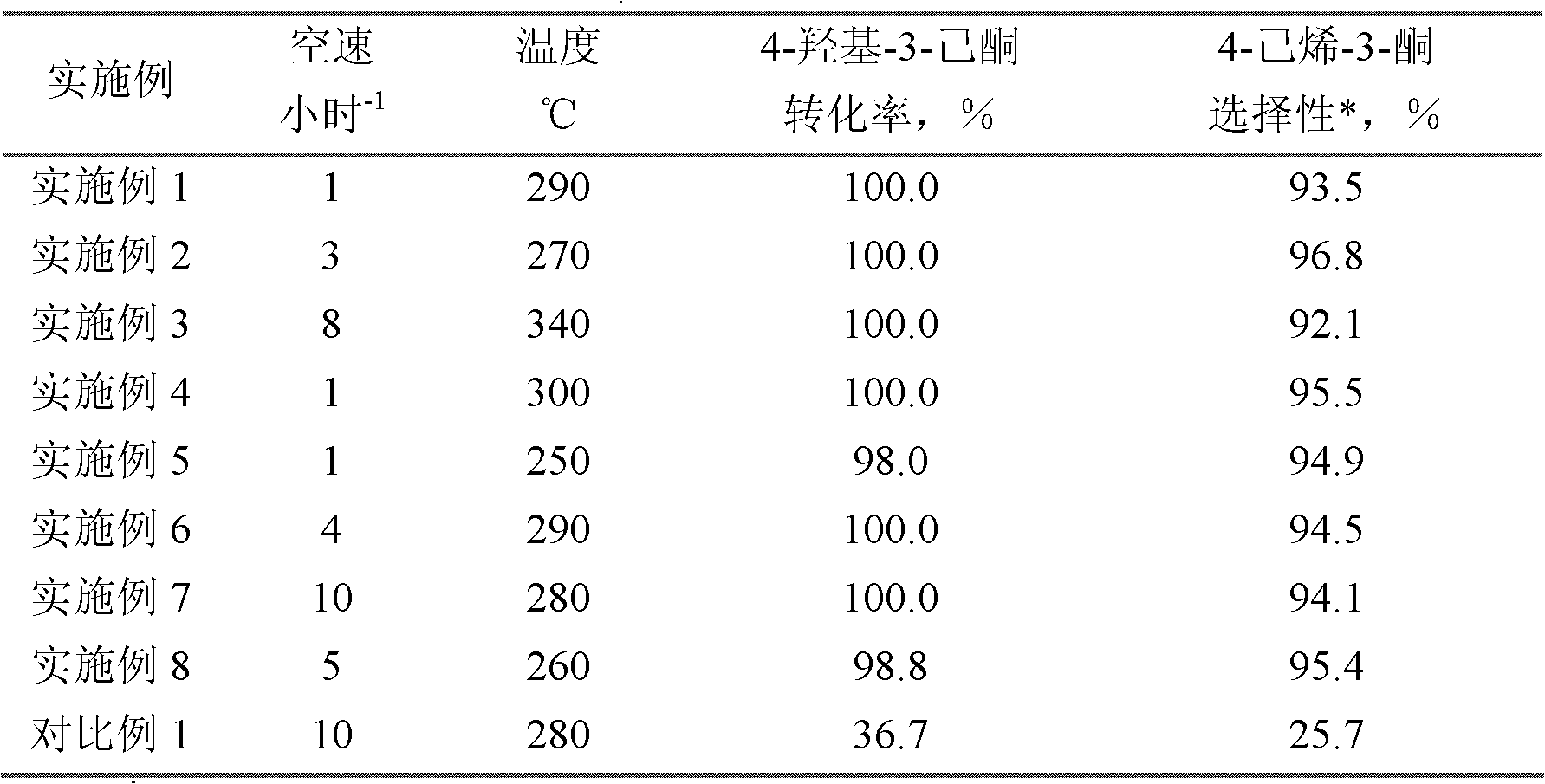

Examples

Embodiment 1

[0017] H 3 Mo 12 o 40 P·nH 2 O is mixed with boehmite, Tianqing powder, and 0.3 mol / liter nitric acid, and the weight ratio of each raw material is H 3 Mo 12 o 40 P / Al 2 o 3 / Tianqing powder=0.13:1:0.1, molded, dried at 120°C for 12 hours, and roasted at 550°C for 10 hours. Al in the catalyst 2 o 3 The parts by weight of is 88 parts, and the parts by weight of heteropolyacid is 12 parts. The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at normal pressure. A stainless steel reactor with an inner diameter of 10 mm was used, the loading amount of the catalyst was 10 ml, the reaction temperature was 290 °C, and the liquid space velocity was 1 hour. -1 , reacted under normal pressure. The reaction product was analyzed by HP 6890 gas chromatography, hydrogen flame detector, and HP-6 capillary column (60m×0.25mm×0.25μm). The reaction results are shown in Table 1.

Embodiment 2

[0019] Press each step and condition of [embodiment 1], only H 4 o 40 SiW 12 / Al 2 o 3 / Tianqing powder=0.20:1:0.1. Al in the catalyst 2 o 3 The parts by weight of is 83 parts, and the parts by weight of heteropolyacid is 17 parts. Catalyst performance was evaluated according to the conditions of [Example 1], except that the reaction temperature was 270°C and the liquid space velocity was 3 hours -1 . The reaction results are shown in Table 1.

Embodiment 3

[0021] Press each step and condition of [embodiment 1], only H 3 o 40 PW 12 / Al 2 o 3 / Tianqing powder=0.20:1:0.1. Al in the catalyst 2 o 3 The parts by weight of is 83 parts, and the parts by weight of heteropolyacid is 17 parts. The catalyst performance was evaluated according to the conditions of [Example 1], except that the reaction temperature was 340°C and the liquid space velocity was 8 hours -1 . The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com