Glass-chip flowing minisize electrolyzer and manufacturing method

A mobile micro-electrolytic cell and micro-electrolytic cell technology, applied in cross fields, can solve the problems that the chip can only be used once, and the membrane electrode cannot be replaced, etc., and achieve the effect of close distance, flexible and convenient electrode configuration, and small voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

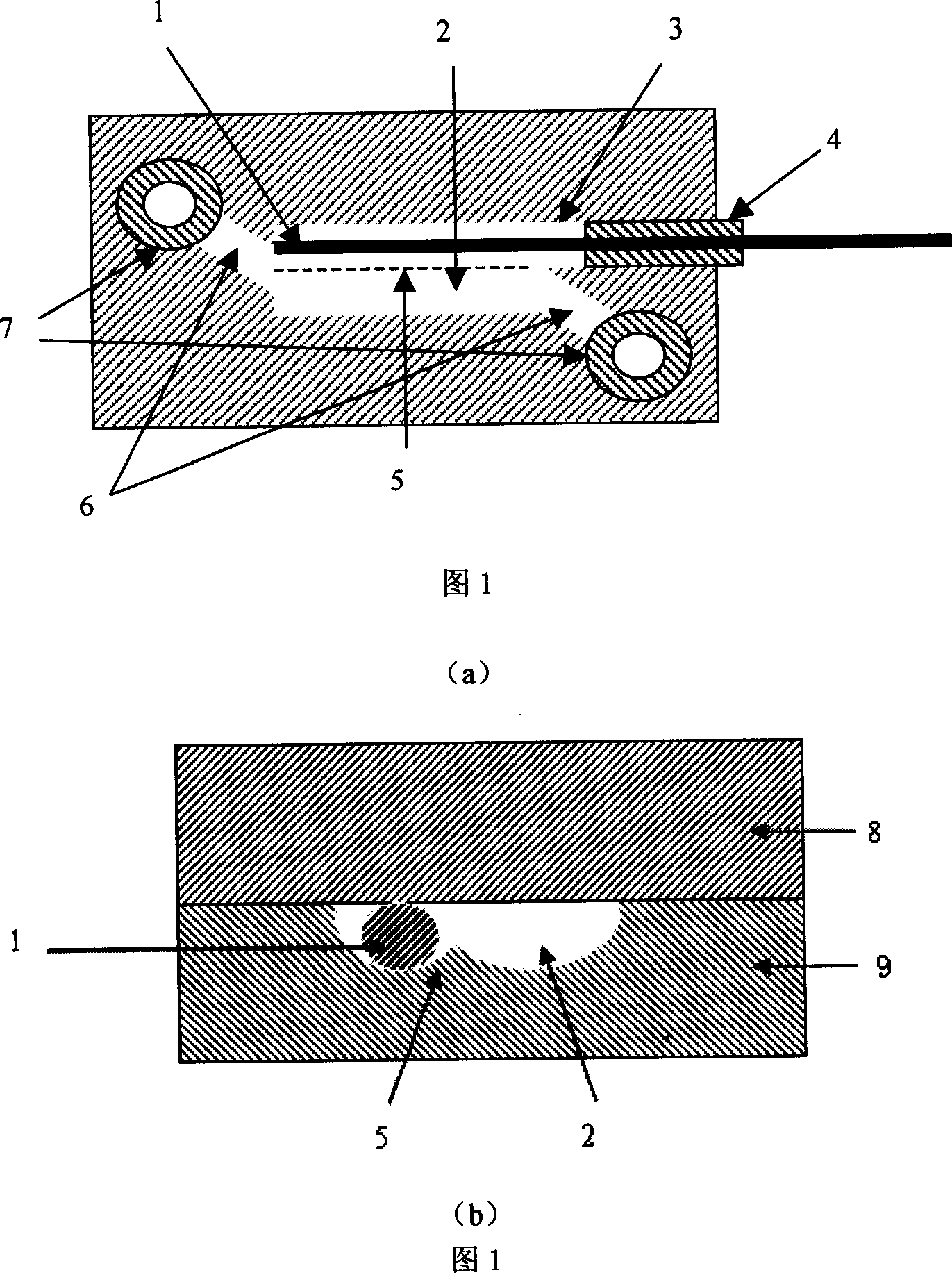

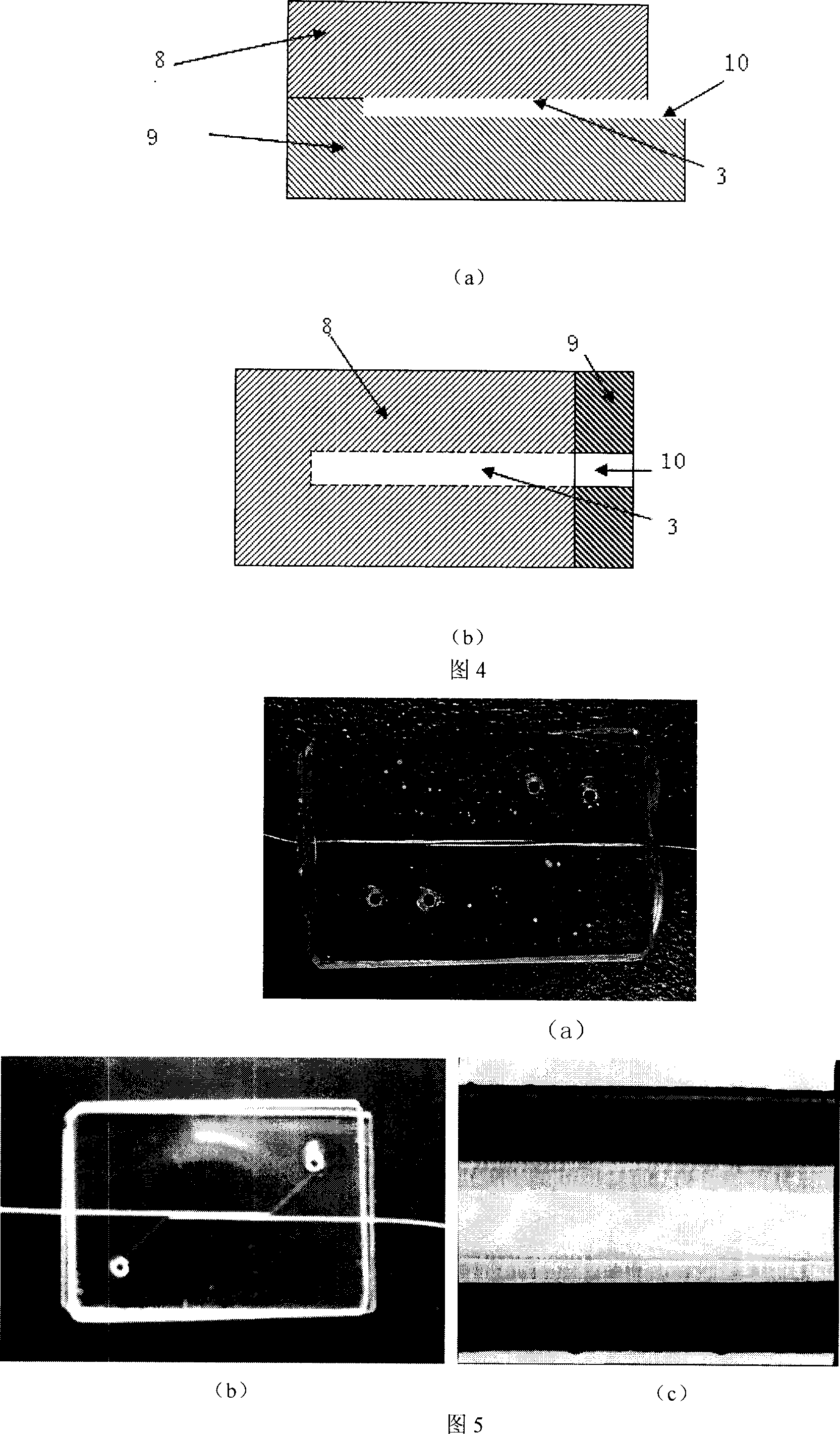

Embodiment Construction

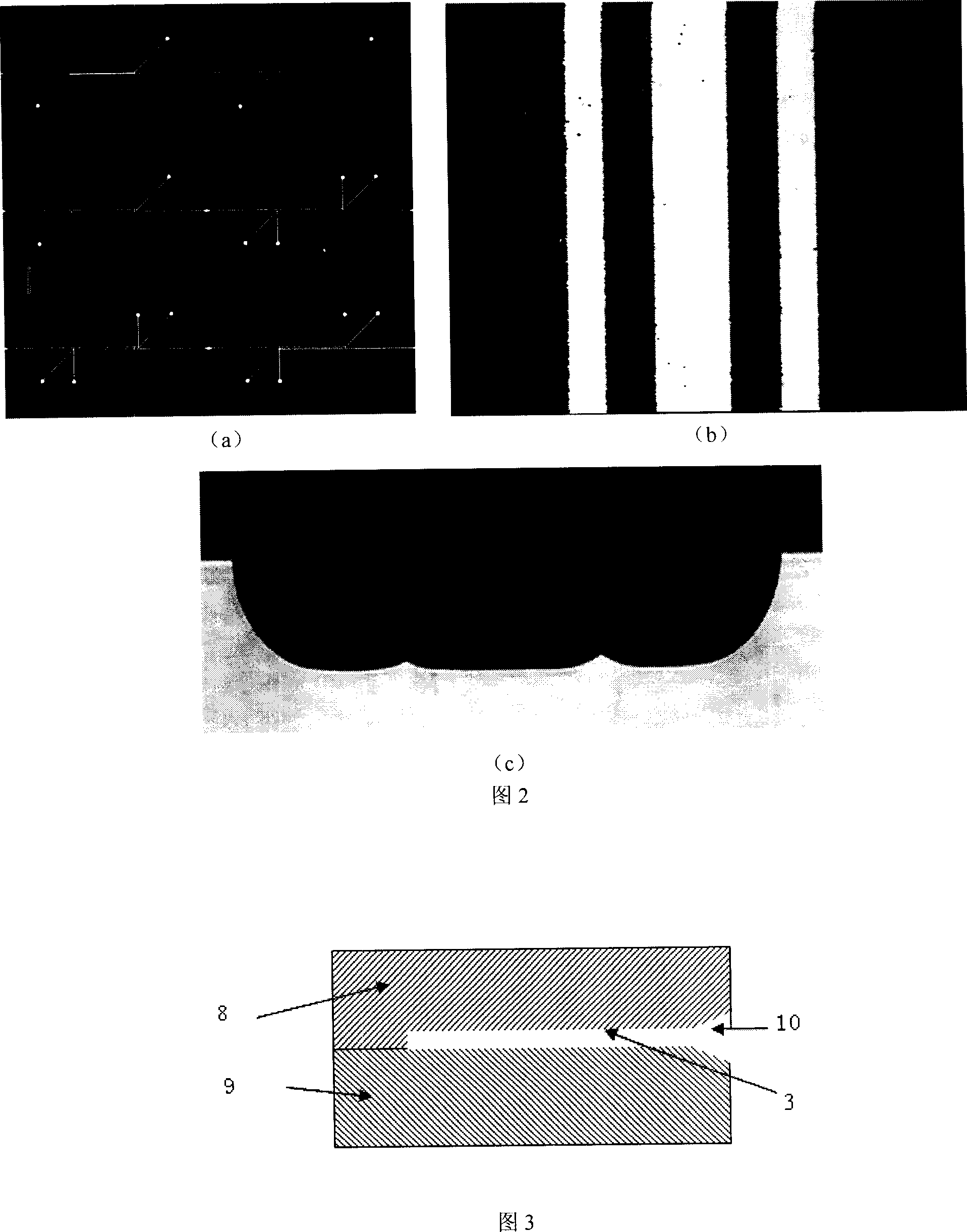

[0031] The specific manufacturing steps of preparing the micro-electrolytic cell chip by photolithography based on laser phototypesetting machine printing mask and wet etching glass substrate are described in detail below.

[0032] 1. Use CoreDraw or similar software to design and generate mask graphics files for microchannels and electrode channels;

[0033] 2. Use a laser phototypesetter to print the graphics file on the polyester film to form a black and white mask;

[0034] 3. Use the UV exposure machine to transfer the mask pattern to the positive photoresist (AZ4650) surface on the chrome plate glass (Changsha Shaoguang, SG2506 type):

[0035] 4. Dip the exposed glass substrate in 0.5% NaOH solution for 40-60 seconds to expose the graphic structure;

[0036] 5. Transfer the chip to an oven at 110°C and bake for about 15 minutes to make the photoresist film firm;

[0037] 6. Soak in the chromium removal solution for about 2 minutes under gentle shaking to remove the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com