Method for preparing composite material of aluminium silicon carbide and structural piece

A composite material, aluminum silicon carbide technology, used in electrical components, manufacturing tools, electrical solid devices, etc., can solve the problems of high density, high expansion coefficient and low thermal conductivity of Kovar alloy, and achieve low cost and thermal conductivity. The effect of high rate and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

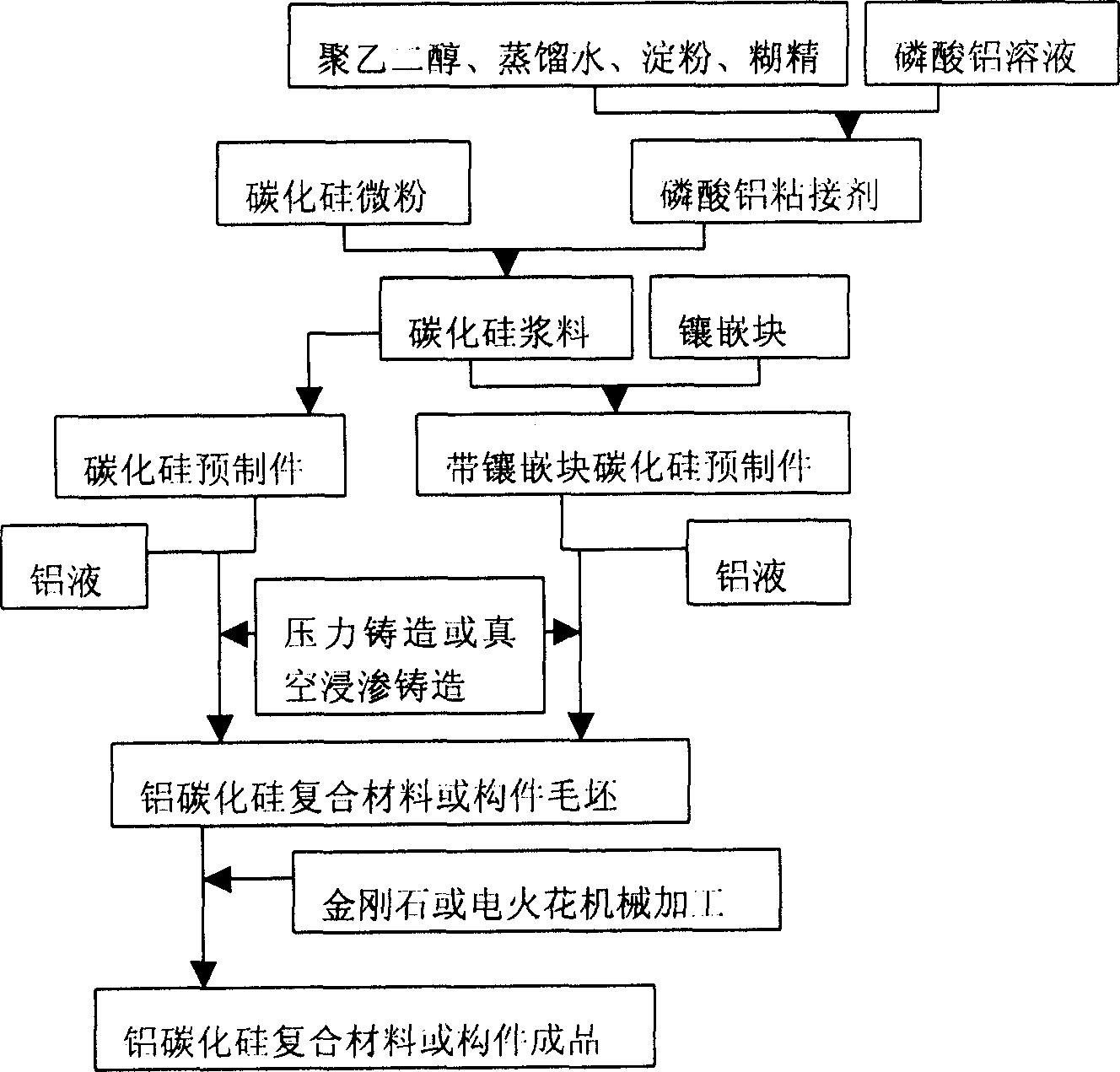

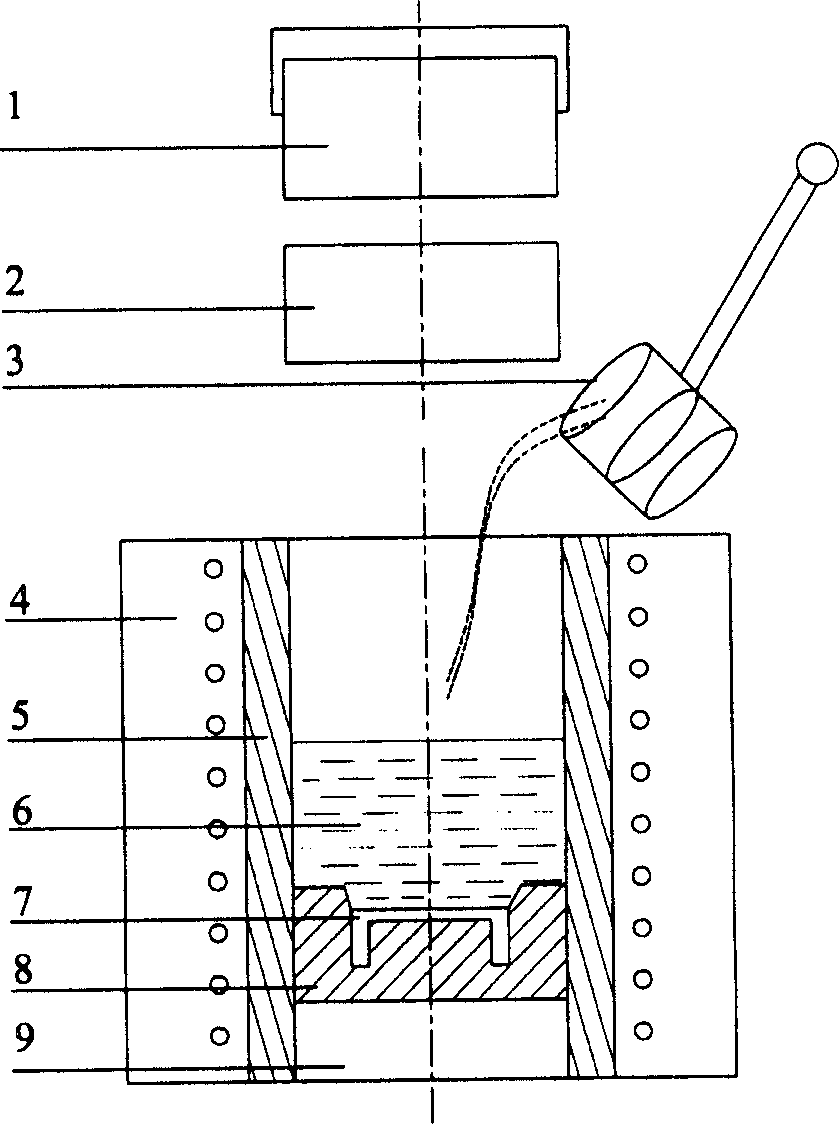

[0031] Embodiment 1 (composite material): prepare the aluminum phosphate solution that phosphorus atom ratio is 23 to aluminum atom; Get 100 gram molecular weight and be the polyethylene glycol melting of 6000, stir after adding 100ml distilled water, 18 gram dextrin and 18 gram glutinous rice flour , then add 100ml of aluminum phosphate solution and 1000 grams of silicon carbide micropowder with a particle size of W28 and stir evenly; weigh an appropriate amount of silicon carbide slurry, and unidirectionally mold it to obtain a green silicon carbide preform of 80mm×50mm×10mm or φ90×15mm. The air furnace was raised to 650°C at a rate of 1.5°C / min for 1.5 hours to obtain a silicon carbide preform. use figure 2 The aluminum silicon carbide composite material is prepared by the die casting method shown, and the specific process parameters are as follows: the preform is heated to 620°C for 1 hour, the forming mold is heated to 340°C for 1 hour, and the ZL101A is melted and heate...

Embodiment 2

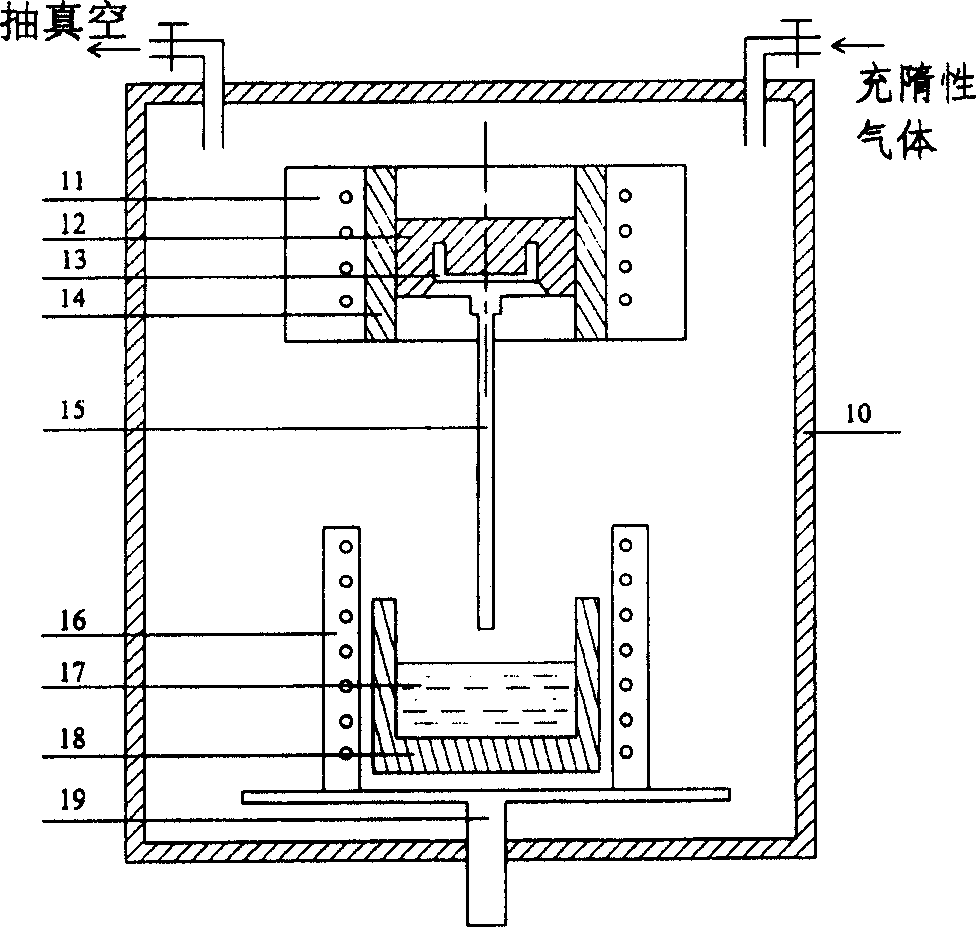

[0034] Embodiment 2: the aluminum phosphate solution that the atomic ratio of phosphorus to aluminum is 10; 5 grams of polyethylene glycol with a molecular weight of 10000, 10 ml of distilled water, 5 grams of dextrin, 5 grams of glutinous rice flour and 10 ml of aluminum phosphate solution are mixed to obtain Aluminum phosphate adhesive, add 100ml of silicon carbide micropowder ball mill and mix to obtain silicon carbide slurry, weigh 20 grams of silicon carbide slurry to obtain bidirectional molding Figure 4 For the silicon carbide preform green body shown, the silicon carbide preform is obtained by raising the temperature at 1.5°C / min to 700°C for 1 hour, and the vacuum infiltration method is used to prepare aluminum silicon carbide composite components. The specific process parameters are as follows: vacuum chamber pressure 5Pa, the silicon carbide preform and molding mold are heated at 720°C for 2 hours, the 6063Al alloy is melted and heated at 760°C for 1 hour, the infil...

Embodiment 3

[0035] Example 3: Figure 5Many circles and rings in the schematic diagram of the components shown require ceramic components to be embedded. Since the ceramic components have low dimensional accuracy and the component requires high air tightness, the ceramic components must be embedded in the silicon carbide preform. Mix aluminum phosphate solution with phosphorus atomic ratio to aluminum atomic ratio of 28, 50 grams of polyethylene glycol with a molecular weight of 12000, 20 ml of distilled water, 10 grams of dextrin, 10 grams of glutinous rice flour and 60 ml of aluminum phosphate solution to make aluminum phosphate bonding Add 500 grams of silicon carbide powder and stir evenly to obtain a silicon carbide slurry, use bidirectional molding to obtain a green silicon carbide preform for inlaid ceramic parts, heat up to 800°C at a rate of 0.7°C / min for 2 hours, and cool in the furnace to obtain the required carbonization Silicon prefabricated parts, using vacuum infiltration m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com