Three-component compound magnetoelectric material using organic polymer as adhesive and its preparation method

A technology of organic polymers and magnetoelectric materials, applied in the manufacture/assembly of magnetostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, etc., can solve the difficulties in the preparation and processing of Terfenol-D sheets, PZT sheet processing difficulty, difficult processing and other problems, to achieve the effect of convenient molding, good mechanical properties of materials, high magnetoelectric conversion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 (type 0-3):

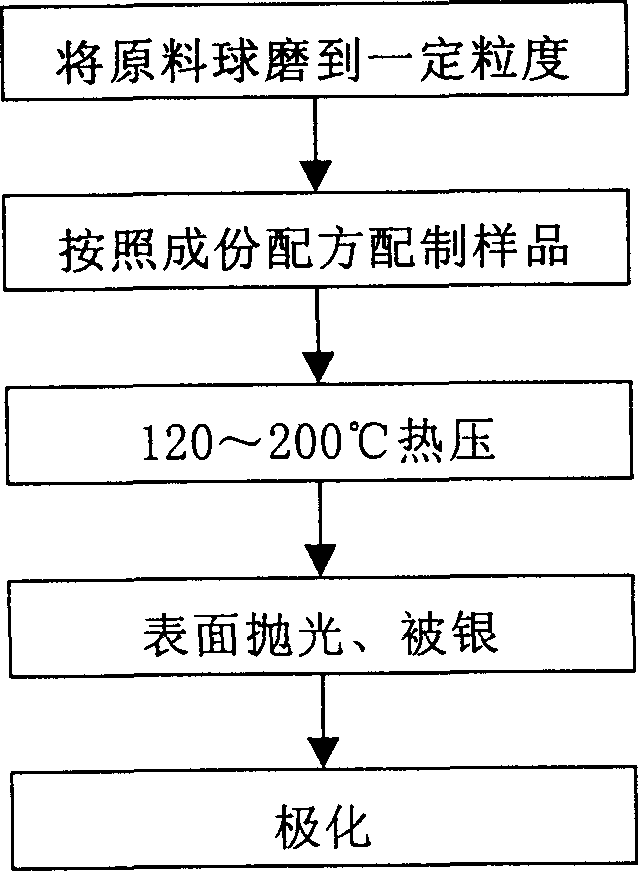

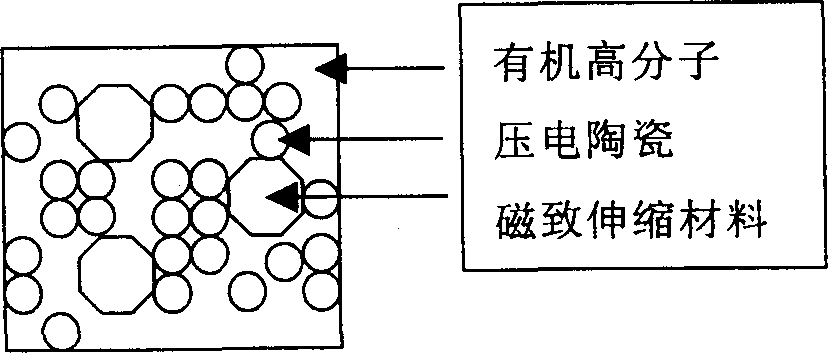

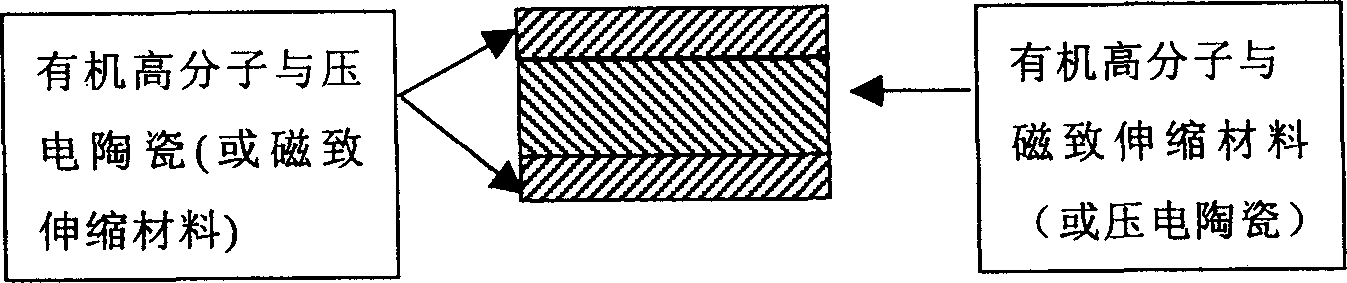

[0059] The ball-milled BT, Terfenol-D and PVDF powders are evenly mixed according to the volume percentage of 60%: 2%: 38%, and then the mixed powder is poured into the mold, and hot pressed at 180 ° C on the powder tablet press (the pressure is 8 MPa , the time is 25 minutes) forming, to obtain the required 0-3 type structural material, the process flow is as follows figure 1 As shown, its surface is polished, covered with silver electrodes, and then polarized in heated silicone oil with a polarization intensity of 3kv / mm. Its microstructure is as Figure 4 As shown, the magnetoelectric conversion coefficient is 1.0-2.2mv / cm Oe, and its change curve is shown in Figure 5.

Embodiment 2

[0060] Embodiment 2 (type 0-3):

[0061] The ball-milled PT, Terfenol-D and polyethylene (PE) powders are mixed evenly according to the volume percentage of 65%: 4%: 31%, and then the mixed powder is poured into the mold, and hot-pressed at 120°C on a powder tablet press (Pressure 10MPa, time is 30 minutes) molding, obtain required 0-3 structure material, technological process such as figure 1 As shown, its surface is polished, covered with silver electrodes, and then polarized in heated silicone oil with a polarization intensity of 3kv / mm. Its microstructure is as Image 6 As shown, the magnetoelectric conversion coefficient is 2 ~ 10mv / cm Oe, and its change curve is shown in Figure 7.

Embodiment 3

[0062] Embodiment 3 (type 0-3):

[0063] The ball-milled PZT, Terfenol-D and polyvinylidene fluoride (PVDF) powders are mixed evenly according to the volume percentage of 75%: 5%: 20%, and then the mixed powder is poured into a mold, and the powder is placed on a powder tablet machine at 200 ° C. Hot pressing (pressure 10MPa, time 30 minutes) molding to obtain the required 0-3 structure material, the process flow is as follows figure 1 As shown, its surface is polished, covered with silver electrodes, and then polarized in heated silicone oil with a polarization intensity of 3kv / mm. Its microstructure is as Figure 8 As shown, the magnetoelectric conversion coefficient is 6-15mv / cm Oe, and its change curve is shown in Figure 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com