Cellulose-based degradable antibacterial peptide and preparation method thereof

A technology of cellulose and antimicrobial peptides, applied in the field of antimicrobial peptides, can solve the problems of poor resistance to proteolytic enzymes, reduced activity of antimicrobial peptides, and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

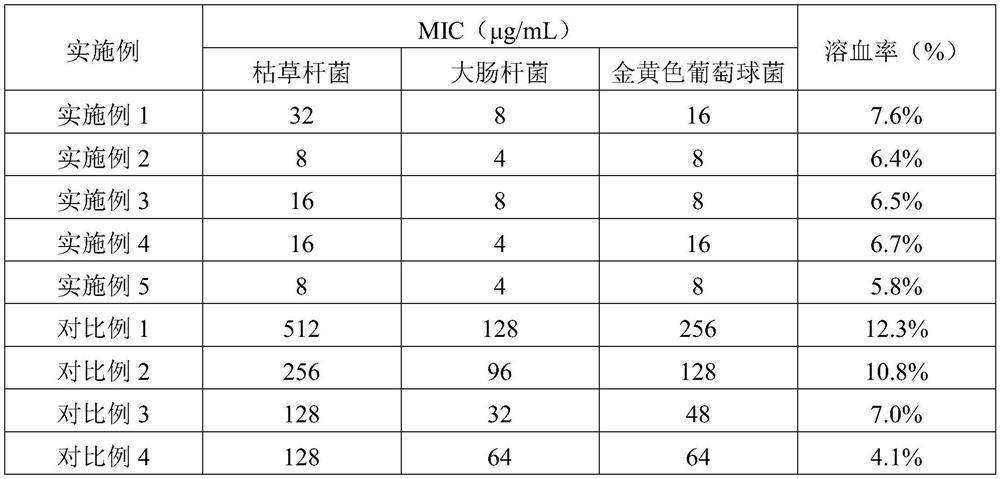

Examples

Embodiment 1

[0027] Step 1: Add 2 g of carboxymethyl cellulose to 20 mL of sulfuric acid solution with a concentration of 50%, acid treatment at room temperature for 2 hours, and ethanol to terminate the reaction; centrifuge at a centrifugal speed of 6000 rmp for 10 minutes, wash and freeze-dry to obtain fibers prime A;

[0028] Step 2: Disperse cellulose A in deionized water to obtain a cellulose solution; adjust pH=9, add 1-(3-dimethylaminopropyl)-3-ethylcarbeneimide, N-hydroxythiol Succinimide sodium salt, stirring for 2 hours; adding excess 5-diaminopentane, stirring for 12 hours, adding methoxypolyethylene glycol amine, reacting for a period of time; ethanol precipitation, centrifugation, washing, freeze-drying; It is ultrasonically dispersed in water, adjusted to pH=3.5 with 0.1M hydrochloric acid, stirred for 4 hours, washed, dialyzed and freeze-dried to obtain degradable antimicrobial peptides.

[0029] In the technical scheme, the added amount of 5-diaminopentane accounts for 20%...

Embodiment 2

[0031] Step 1: Add 2 g of carboxymethyl cellulose into 20 mL of sulfuric acid solution with a concentration of 50%, treat with acid for 1 to 6 hours at room temperature, and terminate the reaction with ethanol; centrifuge at a centrifugal speed of 6000 rmp for 10 minutes, wash, freeze-dry, to obtain cellulose A;

[0032]Step 2: Disperse cellulose A in deionized water to obtain 0.1 g / mL cellulose solution, adjust pH=9, add 1-(3-dimethylaminopropyl)-3-ethylcarbeneimide, N-Hydroxysulfosuccinimide sodium salt, stirred for 2 hours; added excess diamino compound, stirred for 8 hours; added methoxypolyethylene glycol amine, added 0.1M hydrochloric acid to adjust pH=5, stirred for 6 hours Ethanol precipitation, centrifugation, washing, freeze-drying; ultrasonically dispersing it in water, using 0.1M hydrochloric acid to adjust pH=3.5, stirring for 4 hours, adding tetrabutylammonium hydroxide solution dropwise, and continuing to stir for 3 hours; Washing, dialysis, freeze-drying to ob...

Embodiment 3

[0035] Step 1: Add 2 g of carboxymethyl cellulose into 20 mL of sulfuric acid solution with a concentration of 40%, acid treatment at room temperature for 6 hours, and ethanol to terminate the reaction; centrifuge at a centrifugal speed of 6000 rmp for 10 minutes, wash and freeze-dry to obtain fibers prime A;

[0036] Step 2: Disperse cellulose A in deionized water to obtain 0.1 g / mL cellulose solution, adjust pH=9, add 1-(3-dimethylaminopropyl)-3-ethylcarbeneimide, N-Hydroxythiosuccinimide sodium salt, stirred for 2 hours; added excess diamino compound, stirred for 6 hours; added methoxypolyethylene glycol amine, added 0.1M hydrochloric acid to adjust pH=5, stirred for 10 hours ; Ethanol precipitation, centrifugation, washing, freeze-drying; ultrasonically dispersing it in water, using 0.1M hydrochloric acid to adjust pH=3.5, stirring for 4 hours, adding tetrabutylammonium hydroxide solution dropwise, and continuing to stir for 4 hours; Washing, dialysis, freeze-drying to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com