Water-based release glue as well as preparation method and application thereof

A release, water-based technology, applied in coatings, polyester coatings, etc., can solve the problem of difficult adhesion between the primer layer and the polyester layer, substandard adhesion between the ink layer and the primer layer, ink and primer layer. Adhesion is not up to standard and other problems, to achieve the effect of good adhesion and peeling balance, good printing decoration effect and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

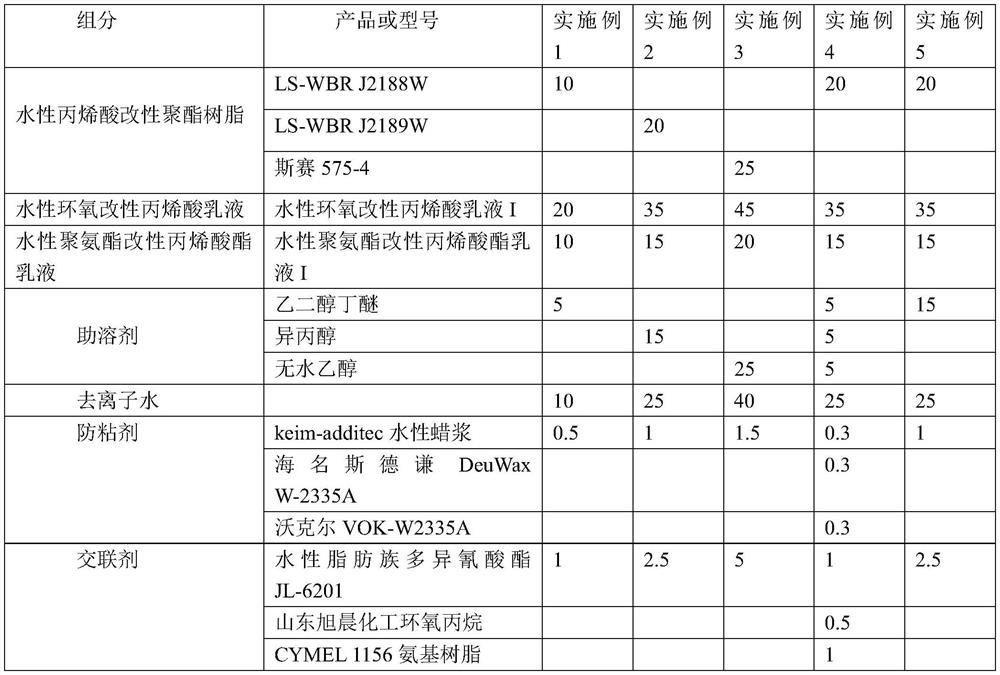

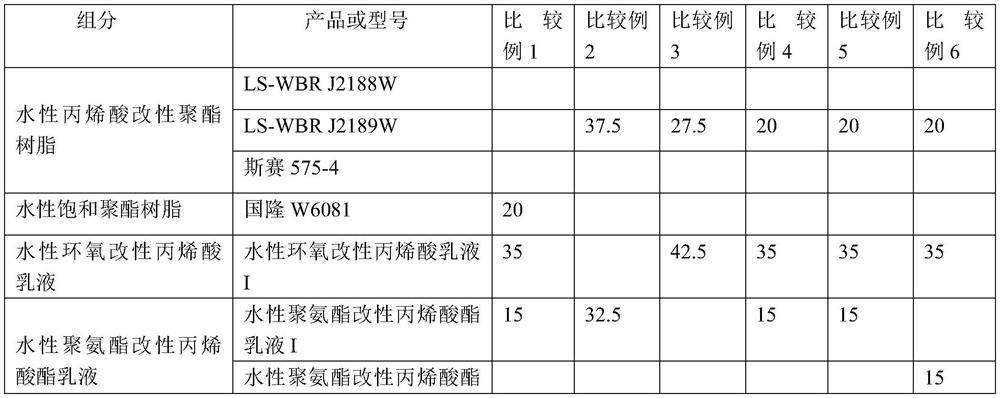

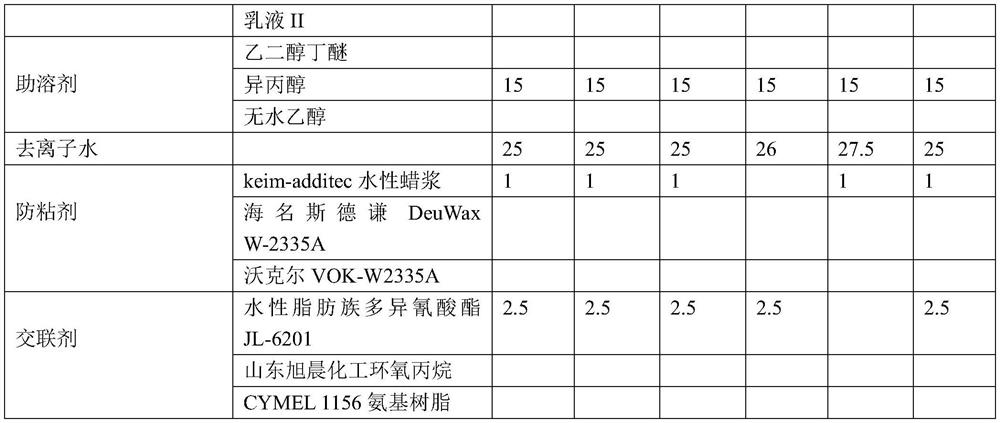

Examples

preparation example 1

[0035] Preparation Example 1, Waterborne Epoxy Modified Acrylic Emulsion I

[0036] Mix 780g epoxy resin E44, 1g dimethylbenzylamine, 0.1g hydroquinone, and 90g propylene glycol methyl ether, heat to 80-100°C, and then slowly add a mixture of 202g crotonic acid and 40g propylene glycol methyl ether. The reaction is performed at a constant temperature for 2-3 hours after the dropwise addition is complete, and when the acid value is less than 3 mgKOH / g, the reaction is stopped to obtain the modified epoxy resin E44.

[0037] Mix 360 g of hydroxyethyl methacrylate, 350 g of methacrylic acid, 300 g of cyclohexyl methacrylate, 250 g of butyl acrylate, and 60 g of azobisisobutyronitrile, stir evenly, and add modified epoxy resin E51 to dissolve completely to obtain mono body mixture. Another 5g of disproportionated sodium rosin and 5g of poloxamer were mixed with 150g of water, and the monomer mixture was slowly added. After adding, the mixture was stirred at high speed for 30 minu...

preparation example 2

[0039] Preparation Example 2, Waterborne Polyurethane Modified Acrylate Emulsion I

[0040] 226g of lysine diisocyanate and 450g of N,N-diethylethanolamine were mixed, stirred and heated to 60°C, vacuumed to -0.095MPa and reacted for 30min, then heated to 80°C and reacted for 2h to obtain a polyurethane prepolymer. 145 g of acrylic acid-β-hydroxyethyl ester was added to cap the polyurethane prepolymer, and the reaction was carried out for 2 h to obtain a polyurethane crosslinking agent.

[0041] Mix 12g of octylphenol polyoxyethylene ether, 6g of disproportionated sodium rosinate, 280g of water and 2.5g of sodium bicarbonate, stir and fully dissolve to obtain an emulsion, then mix 360g of ethyl acrylate, 515g of ethyl 2-methacrylate and 17g of polyurethane cross-linking agent was stirred evenly to obtain a monomer solution. The monomer solution and potassium persulfate solution (containing 5g of potassium persulfate and 130g of water) were slowly added to the emulsion at 80°C ...

preparation example 3

[0042] Preparation Example 3, Waterborne Polyurethane Modified Acrylate Emulsion II

[0043] After mixing 125 g of diphenylmethane diisocyanate and 225 g of dehydrated polyether diol DL-2000, the temperature was raised to 60°C with stirring, and vacuumed to -0.095MPa for reaction for 40min, and then heated to 80°C for reaction for 2h to obtain polyurethane prepolymer. 58 g of acrylic acid-β-hydroxyethyl ester was added to cap the polyurethane prepolymer, and the reaction was carried out for 2 h to obtain a polyurethane crosslinking agent.

[0044] Mix 10.7g of octylphenol polyoxyethylene ether, 5.3g of sodium lauryl sulfate, 224g of deionized water and 1.3g of sodium bicarbonate, and then stir and fully dissolve to obtain an emulsion; then mix 24g of methyl methacrylate, 40g of Butyl acrylate and 15.5g of polyurethane cross-linking agent were stirred evenly to obtain a monomer solution; 3.2g of potassium persulfate was fully dissolved in 100g of deionized water to obtain a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com