Silver-carried alginic acid fiber and preparation method thereof

An alginate fiber and silver-carrying technology can be used in fiber processing, textiles, and papermaking, etc., and can solve unevenness; such as the Chinese invention patent, alginate fiber dressings are easy to harden, and the treatment uniformity is poor. Ease of processing and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

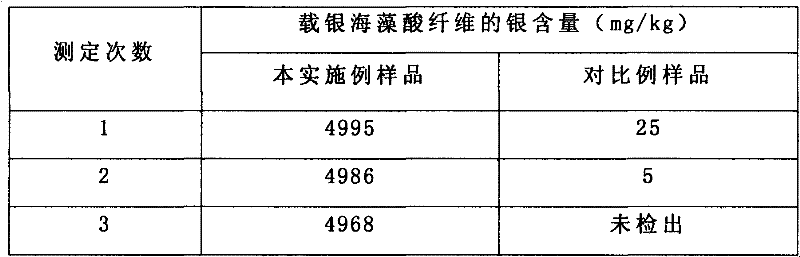

Embodiment 1

[0018] The Chinese invention patent "Method for preparing nano-silver colloidal solution" with the publication number CN101837465A discloses a technical scheme for preparing a nano-silver colloidal solution, which combines an alkylated cyclodextrin aqueous solution with a mass percentage of 0.1% to 10% The silver ammonia solution with a molar concentration of 0.01 to 1.0 mol / L is mixed in a volume ratio of 1:100 to 1:10, and stirred at a temperature of 10 to 100°C for 1 to 120 minutes to obtain an average particle size of 1 to 100nm nano silver colloidal solution.

[0019] In this embodiment, according to the above technical scheme, the alkylated cyclodextrin aqueous solution with a mass percentage of 0.5% and the silver ammonia solution with a molar concentration of 0.5 mol / L are mixed at a volume ratio of 1:10, and the mixture is mixed at a volume ratio of 1:10. Stir for 20 minutes at a temperature of ℃ to obtain a nano-silver colloidal solution with an average particle size of...

Embodiment 2

[0029] According to the technical scheme of Example 1, an aqueous solution of nano silver was prepared.

[0030] Immerse 1 kg of alginic acid fiber in the above-mentioned nano silver aqueous solution with a concentration of 20ug / L, and immerse the place for 60 minutes at a bath ratio of 1:100, and then take out the silver-loaded alginate fiber enriched with adsorbed elemental silver particles, A kilogram of 80% (V / V) acetone aqueous solution was washed and dried to obtain fluffy and soft silver-loaded alginate fiber with a silver content of about 2000 mg / kg.

Embodiment 3

[0032] According to the technical scheme of Example 1, an aqueous solution of nano silver was prepared.

[0033] Dip 1 kg of alginic acid fiber in a nano-silver aqueous solution with a concentration of 200ug / L, bath ratio 1:50, soak for 60 minutes, then take out the silver-loaded alginate fiber enriched with adsorbed elemental silver particles, and wash with 30 kg of chloroform After drying, a fluffy and soft silver-loaded alginate fiber with a silver content of about 10,000 mg / kg is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com