Ferrite stainless steel having excellent antibacterial characteristics

A technology of stainless steel and ferrite, applied in the field of ferritic stainless steel, can solve the problems of expensive Ag, difficult to obtain yield, lower corrosion resistance of stainless steel, etc., and achieve the effect of excellent antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

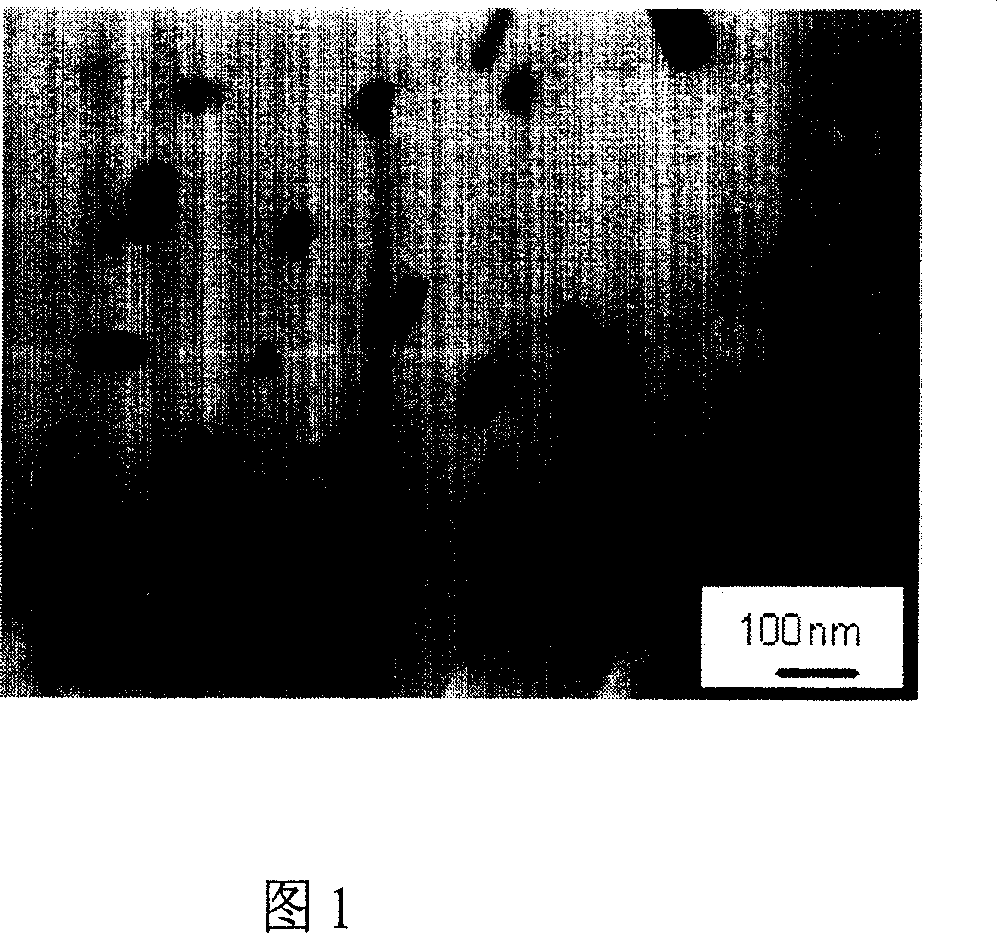

Image

Examples

Embodiment Construction

[0014] Sample preparation: according to the composition of the ferritic antibacterial stainless steel of the present invention, smelt with a 25kg vacuum induction furnace, then through forging, hot rolling and annealing, repeated cold rolling-annealing-pickling, and make a plate of 0.8mm, from the above A sample of 25×25 mm was cut from the plate, kept in a vacuum furnace at 920° C. for 7 minutes, and then aged at 600° C. for 6 hours. Then carry out antibacterial performance test.

[0015] Antibacterial performance test: The specific test is carried out at the Center for Disease Control and Prevention, using the antibacterial detection method of the Japan Antimicrobial Association "Japanese Industrial Standards: Antibacterial Test Methods and Antibacterial Effects of Antibacterial Processed Products" (Japanese Industrial Standard JIS Z2801-2000), using film coating method, with a concentration of 10 5 Cfu / ml of standard bacterial solution under the conditions of temperature 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com