Preparation method of large-size flexible gallium nitride single crystal film

A gallium nitride single crystal, large-scale technology, applied in the semiconductor field, can solve the problems of easy-to-crack GaN film, poor heat dissipation of GaN film, high dislocation density, etc., achieve good heat dissipation performance and ductility, not easy to crack, and reduce dislocations effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

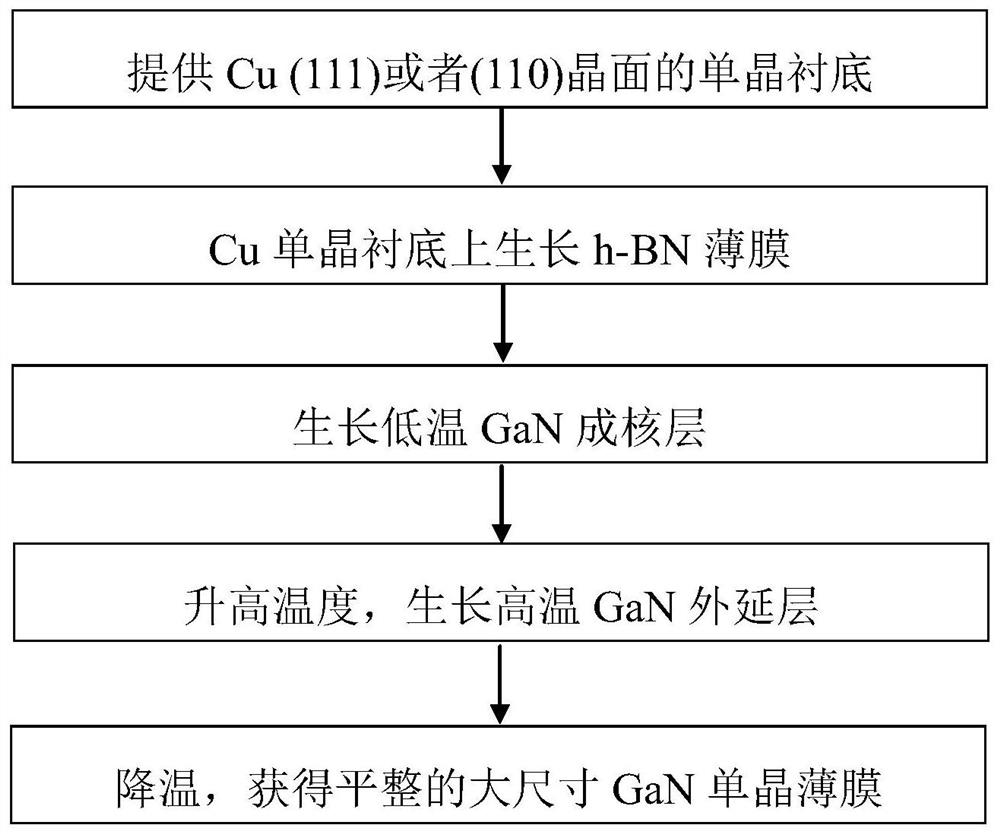

[0046] A preparation method of a large-scale flexible gallium nitride single crystal film, comprising the following steps:

[0047] Step 1: Provide Cu single crystal substrate 1

[0048] The crystal plane of Cu single crystal substrate 1 is (111), and the thickness is 150 μm.

[0049] Step 2: Grow the h-BN thin film layer 2 on the Cu single crystal substrate 1 of Step 1

[0050] The chemical vapor deposition (CVD) method was used, borane ammonia was used as the precursor, the purity of the borane ammonia was 97%, the growth pressure was 160Pa, the precursor temperature was set to 75°C, and the growth temperature on the Cu single crystal substrate 1 was The temperature was 1040 °C, the growth time was 1 h, and the growth thickness was 200 nm.

[0051] Step 3: grow a low temperature GaN nucleation layer 3 on the h-BN thin film layer 2 grown in step 2

[0052] Using the HVPE process, the temperature is set to 680°C, the pressure is set to 700 Torr, the V / III is set to 130, the...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is that the crystal plane of the Cu single crystal substrate 1 is (110), and the dislocation density test of SEM, AFM and cathode fluorescence is also carried out on it, and the obtained results are the same as those of Embodiment 1. quite.

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 is that the crystal plane of the Cu single crystal substrate 1 is (100), and the resulting GaN film has poor uniformity and large roughness. The SEM inspection results are as follows Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com