Epitaxial wafer, epitaxial wafer growth method and high electron mobility transistor

A growth method and epitaxial wafer technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of leakage, reduce device performance, cannot achieve high resistance, etc., to improve crystal quality, reduce leakage, and improve clamping. The effect of breaking characteristics and withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

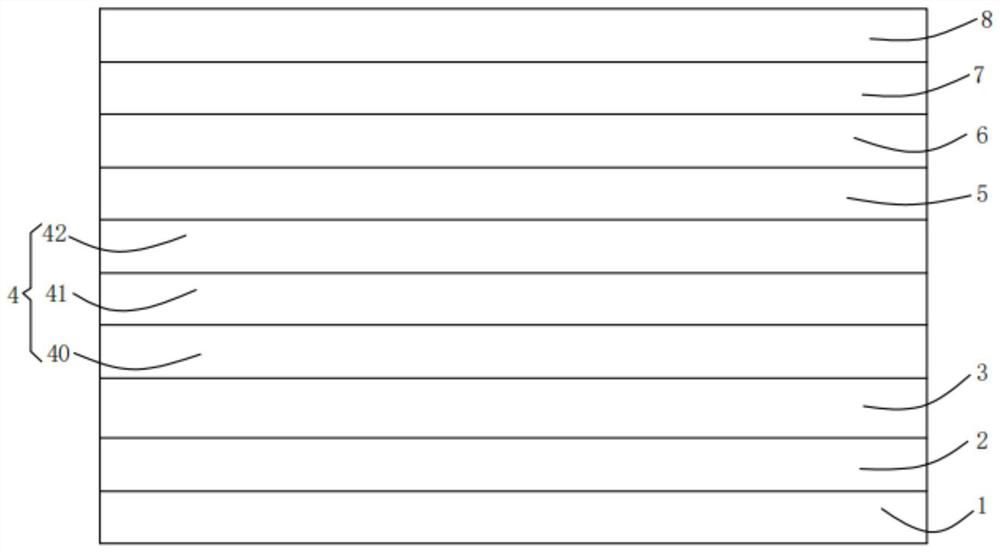

[0026] see figure 1 , is the epitaxial wafer provided in the first embodiment of the present invention, the epitaxial wafer includes a Si substrate 1, an AlN nucleation layer 3, a high resistance buffer layer 4, a GaN channel layer 5, an AlN insertion layer 6, The AlGaN barrier layer 7 and the GaN cap layer 8, and the high-resistance buffer layer 4 include a first carbon-doped AlGaN layer 40, a second carbon-doped AlGaN layer 41 and a third carbon-doped AlGaN layer 42 that are stacked in sequence. The carbon-doped AlGaN layer 40 is arranged on the side close to the AlN nucleation layer 3;

[0027] The doping concentration of the first carbon-doped AlGaN layer 40 is uniformly graded from high to low, the doping concentration of the second carbon-doped AlGaN layer 41 is constant, and the doping concentration of the third carbon-doped AlGaN layer 42 is given by Low to high uniform gradient.

[0028]It can be understood that by arranging a plurality of carbon-doped AlGaN buffer ...

Embodiment 2

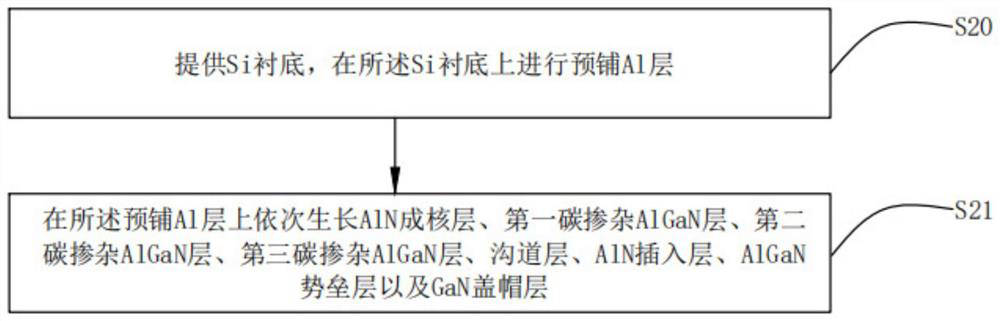

[0033] see figure 2 , is the epitaxial wafer growth method provided in the second embodiment of the present invention, used for growing the epitaxial wafer in the above-mentioned first embodiment, the method includes steps S20-S21:

[0034] Step S20, providing a Si substrate, and pre-spreading an Al layer on the Si substrate;

[0035] Among them, an Al layer is pre-laid on the substrate, which can inhibit the interface reaction between the Si substrate and the epitaxial layer. Specifically, the growth temperature of the pre-laid Al layer is 1000-1100 °C, the pressure is 40-70 mbar, and the The flow rate of the incoming Al source is 50-200 sccm.

[0036] In addition, in order to improve the growth effect of the epitaxial wafer, in some optional embodiments of the present invention, the providing a Si substrate, and before the step of pre-spreading an Al layer on the Si substrate, further includes:

[0037] The Si substrate is deoxidized at a chamber temperature of 1000-1200°...

Embodiment 3

[0044] The third embodiment of the present invention provides a high electron mobility transistor, including the epitaxial wafer in the above-mentioned first embodiment, and the epitaxial wafer can be obtained by epitaxial growth by the epitaxial growth method in the above-mentioned second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com