Aln buffer layer of led and its epitaxial growth method

A technology of epitaxial growth and buffer layer, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult growth of GaN single crystal thin film, large crystal lattice, mismatch thermal mismatch, etc., and achieve the improvement of crystal quality and optoelectronics performance, grain uniformity, dislocation suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present invention utilizes the magnetron sputtering reaction equipment to prepare the AlN buffer layer on the sapphire substrate, with the metal aluminum (Al) that purity is 5.5N as target material, with helium (Ar), nitrogen (N 2 ) and oxygen (O 2 ) is the reactive gas, and the sputtering bias is set to 3000V. Using MOCVD equipment to prepare GaN-based LED epitaxial wafers, using trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum (TMAl) and ammonia (NH3) as sources of Ga, In, Al and N , with silane (SiH 4 ) and dimagnesium (Cp2Mg) as n-type and p-type doping sources. The specific growth method is as follows:

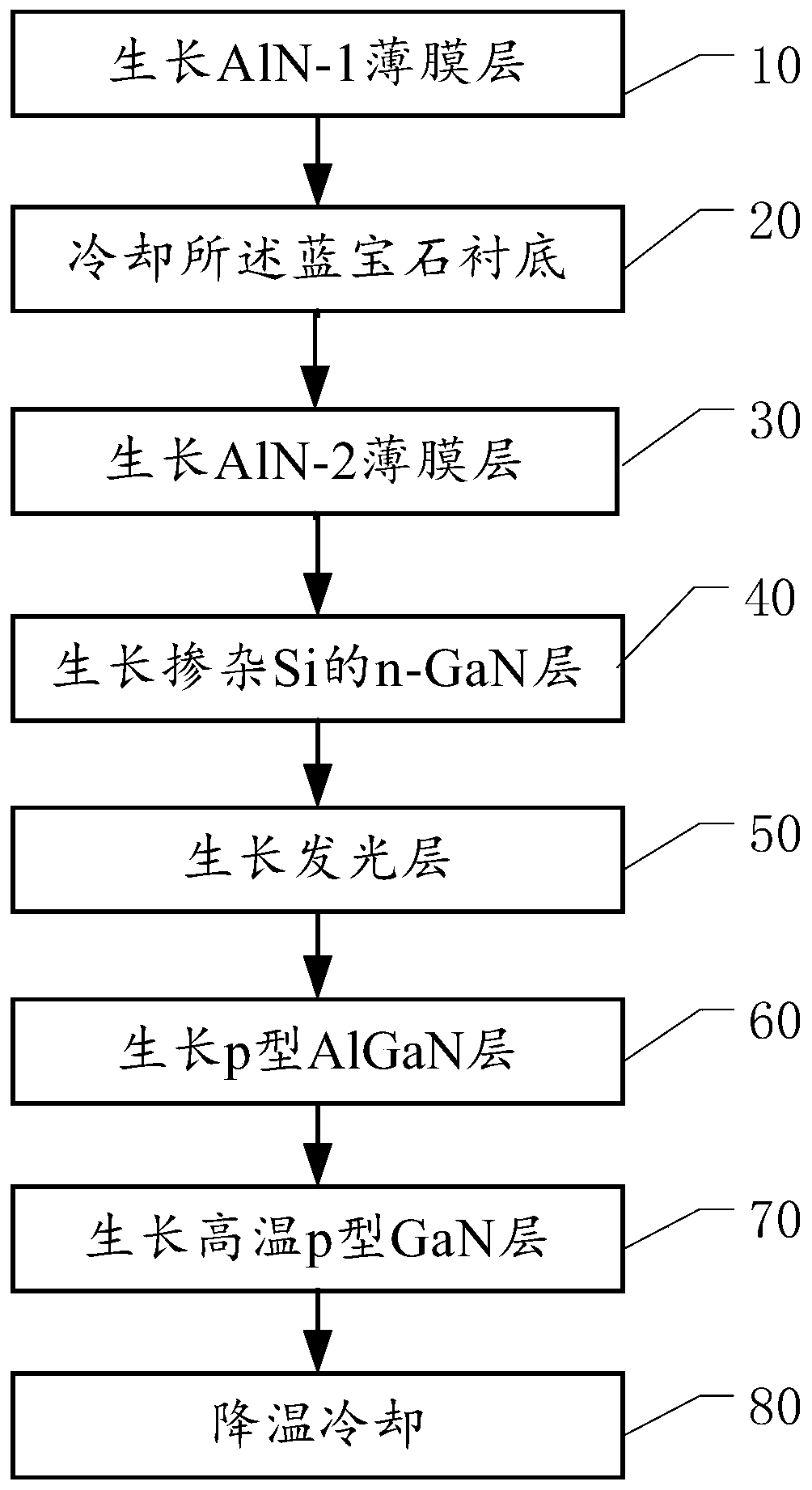

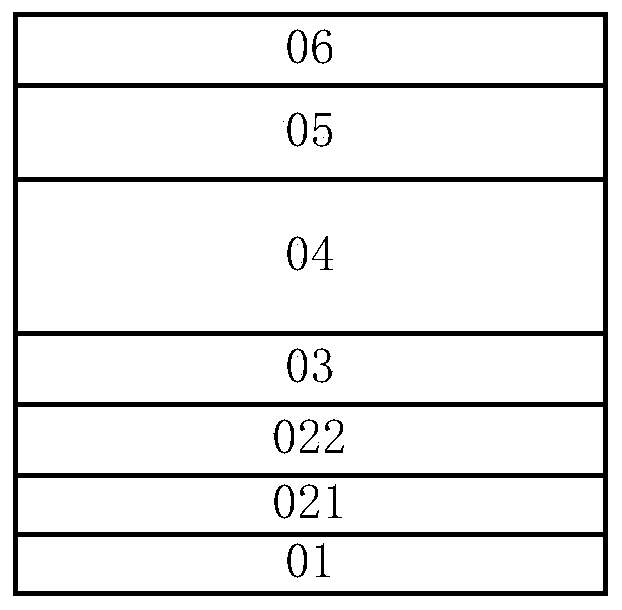

[0044] Please refer to figure 1 and figure 2 , an ALN buffer layer of an LED and an epitaxial growth method thereof, comprising:

[0045] Growing AlN-1 thin film layer, cooling sapphire substrate, growing AlN-2 thin film layer, growing Si-doped n-GaN layer, growing light-emitting layer, growing p-type AlGaN layer, growing high-tempera...

Embodiment 2

[0057] Step 10: growing an AlN-1 film layer, specifically:

[0058] Put the sapphire substrate into the magnetron sputtering reaction equipment, heat the sapphire substrate to 650°C, and feed 30sccm of Ar and 120sccm of N 2 , and 1sccm of O 2 , control the sputtering bias to be reduced from 3000V to 2200V, set the target base distance to 3-4cm, and sputter an AlN-1 film layer with a thickness of 15-20nm on the surface of the sapphire substrate;

[0059] Step 20: cooling the sapphire substrate; for example, cooling for 10 minutes.

[0060] Step 30: growing an AlN-2 thin film layer, specifically:

[0061] Put the sapphire substrate with the AlN-1 thin film layer into the MOCVD reaction chamber, control the temperature to gradually increase from 850°C to 950°C, keep the reaction chamber pressure at 250mbar, and feed 80L / min H 2 , 90L / min of NH 3 , 220sccm TMAl source, and grow an AlN-2 thin film layer with a thickness of 15-20nm on the surface of the AlN-1 thin film layer.

...

Embodiment 3

[0079] A conventional LED growth method is provided below as a comparative example of the present invention.

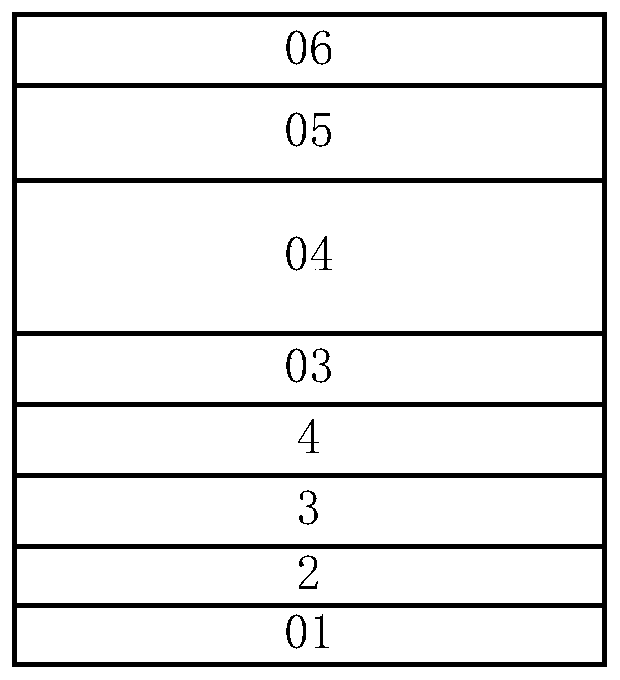

[0080] The growth method of conventional LED epitaxy is (see the epitaxial layer structure image 3 ):

[0081] Step 1, process the sapphire substrate: put the sapphire substrate in the reaction chamber of the metal-organic chemical vapor deposition system, at 900°C-1100°C 2 Under the atmosphere, feed 50L / min-100L / min of H 2 , keep the reaction chamber pressure at 100mbar-200mbar, and process the sapphire substrate for 5min-10min.

[0082] Step 2. Growth of GaN low-temperature buffer layer: cool down to 500°C-600°C, keep the reaction chamber pressure at 300mbar-600mbar, and feed NH with a flow rate of 40L / min-60L / min 3 , 50sccm-100sccm TMGa and 50L / min-90L / min H 2 , growing a GaN low-temperature buffer layer with a thickness of 30nm-60nm on a sapphire substrate.

[0083] Step 3, grow 3D GaN layer: raise the temperature to 850°C-1000°C, keep the reaction chamber p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com