Bismuth-doped rare earth iron garnet single crystal film, preparation method thereof and optical device

An iron garnet, single crystal thin film technology, applied in the field of optical communication, can solve the problems of increased thermal stress and lattice mismatch, increased cracking risk, cracking of the single crystal film layer, etc., so as to eliminate concentration changes and cracking risks. The effect of reducing and reducing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

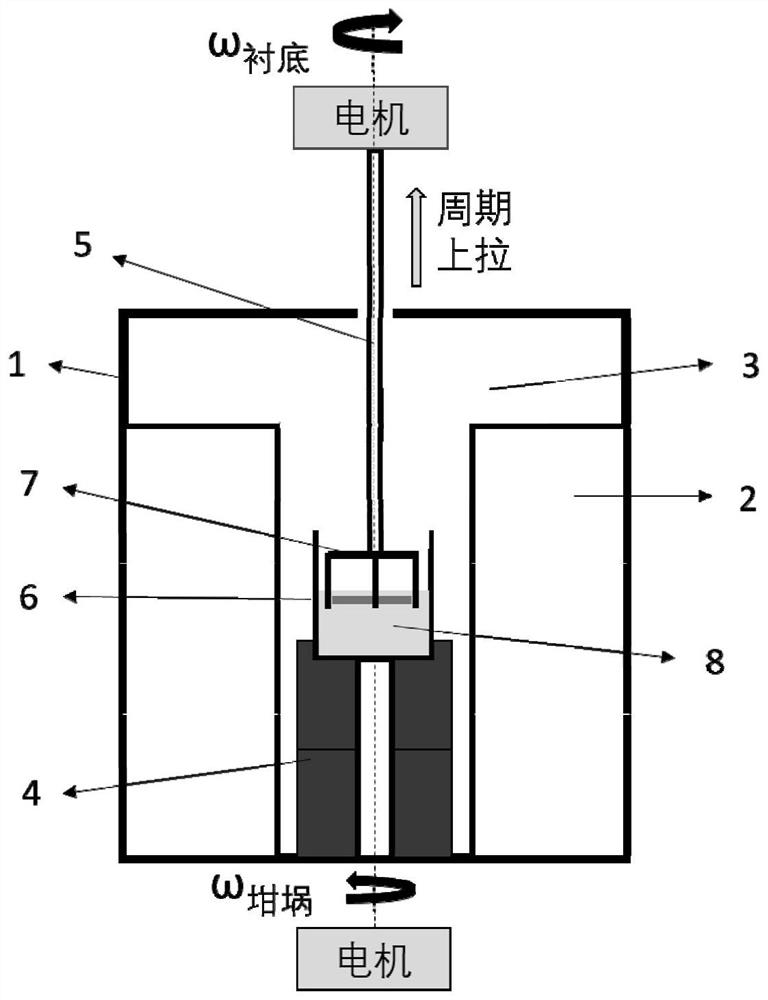

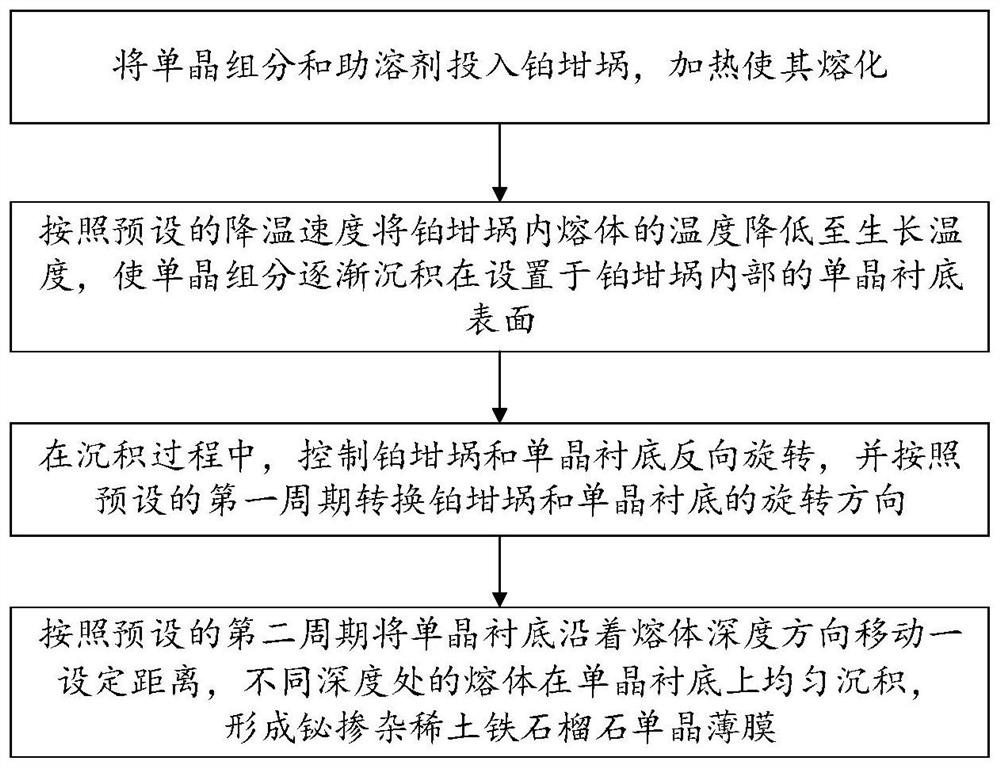

[0042] Combine below figure 2 , the core preparation method of the bismuth-doped rare earth iron garnet single crystal film provided by the present invention is described. In order to prepare a high-performance bismuth-doped rare earth iron garnet single crystal film, the preparation method provided by the present invention includes:

[0043] S1 Put the single crystal component and co-solvent into the platinum crucible, heat it to melt;

[0044] In this embodiment, the configured single crystal component and co-solvent component are added into the platinum crucible 6 of the above-mentioned liquid phase epitaxial growth equipment, and heated until the single crystal component and co-solvent are completely melted.

[0045] The single crystal component refers to the preparation of YIG (yttrium iron garnet, Y 3 Fe 5 o 12 ) of conventional raw materials (Fe 2 o 3 and rare earth R oxides) and Bi element substances used to partially replace Y (such as Bi 2 o 3 ), Ga element m...

Embodiment 1

[0068] A bismuth-doped rare earth iron garnet single crystal film (Bi 3-x R x )(Fe 5-y Ga y )O 12 For preparation methods, see image 3 , and its specific implementation steps are:

[0069] (1) CaMgZr: GGG single crystal substrate with a diameter of two inches is pulled and prepared, processed into a 0.5mm thin slice, and polished on one side, and the measured lattice constant is After cleaning with alcohol, it is ready for use.

[0070] (2) Raw material preparation: Weigh 810g of lead oxide, 1150g of bismuth oxide, 15g of boron oxide, 120g of ferric oxide, 10.5g of terbium oxide, 12.1g of gallium oxide, and 5.1g of ytterbium oxide, and mix well.

[0071] (3) Put the raw material into the platinum crucible, put it into the liquid phase epitaxy furnace, and clamp the CaMgZr:GGG single crystal substrate on the platinum fixture.

[0072] (4) Raise the temperature of the liquid phase epitaxy furnace to 940° C., keep it warm for 10 hours, and then lower the temperature to 7...

Embodiment 2 Embodiment 6

[0078] The bismuth-doped rare earth iron garnet single crystal film (Bi 3-x R x )(Fe 5-y Ga y )O 12 The preparation method, its specific implementation steps are the same as in Example 1, the difference is that the preparation process parameters are different, the preparation process parameters of each embodiment are shown in Table 1, and the obtained single crystal thin film products and corresponding test results are shown in Table 2:

[0079] The process parameter of table 1 embodiment two~embodiment six

[0080]

[0081] The test result of table 2 embodiment two~embodiment six

[0082]

[0083] The minimum thickness of the single-crystal thin film prepared by adopting the recipe provided in Example 6 and the epitaxial growth process is 235 μm, indicating that the 235 μm single-crystal thin film prepared in this example can reach a Faraday rotation angle of 45° in the 1310 nm wave band, and the thinner thickness It has higher growth efficiency and better insertio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Insertion loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com