Method for removing trace pollutants in tap water by catalytic oxidation combined membrane treatment technology

A technology of trace pollutants and catalytic oxidation, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of disinfection by-products, low removal rate of inorganic small molecule pollutants, etc., and enhance the degradation ability. , Improve electron utilization and reaction efficiency, good electrocatalytic activity and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare multi-metal Ti composite oxide as anode material, the specific preparation process is as follows:

[0043] (1) First cut the Ti plate to the required size, and then pre-treat the Ti plate. The pre-treatment is surface cleaning treatment, including degreasing and deoxidizing film on the surface of the metal layer.

[0044] (2) The pretreated Ti plate was treated by surface etching technology, specifically, a mixed solution of hydrofluoric acid and nitric acid with a volume ratio of 1:3 was used for 1 min.

[0045] (3) The preparation process of the mixture slurry of metal and metal oxide is: with acetone as solvent, metal Ti, multi-metal composite oxide (0.05% aluminum, 0.05% tin, 0.90% antimony, 0.5% nickel, 0.5% Iron, 0.3% iridium, 0.2% yttrium, 1.0% platinum, 2.0% titanium oxide, 1.0% yttrium oxide, 1.0% chromium oxide, 1.0% iridium oxide, 1.0% nickel oxide, 1.0% antimony oxide, 1.0% tin oxide, 1.0% nickel oxide), Ti 3 SiC 2 The nano conductive ceramic powd...

Embodiment 2

[0050] Prepare Pt / Ti composite material as cathode material, the specific preparation process is as follows:

[0051] (1) For Pt / Ti / SiO 2 / Si negative film is pretreated, and the pretreatment is surface cleaning;

[0052] (2) Metal and metal oxide are mixed to make metal / metal oxide metal target by powder metallurgy method, the specific metal / metal oxide metal target is made of Pt, Ti, metal composite material (0.06% titanium, 0.10% chromium, 0.03% yttrium, 1.2% aluminum oxide, 1.50% chromium oxide, 1.20% platinum oxide, 0.5% nickel oxide, 0.08% zinc oxide, 0.5% selenium oxide, 1.10% titanium oxide, 1.10% manganese oxide material, 0.08% antimony oxide, 0.5% tin oxide, 0.02% yttrium oxide, 0.03% nickel oxide) in proportions of 12%, 80% and 8%;

[0053] ③Under vacuum conditions, pre-sputter Ti in an inert gas Ar atmosphere, with a current density of 10mA / cm 2 , the pre-sputtering time is 5min;

[0054] ④ Introduce oxygen, and under the condition of oxygen-argon volume ratio ...

Embodiment 3

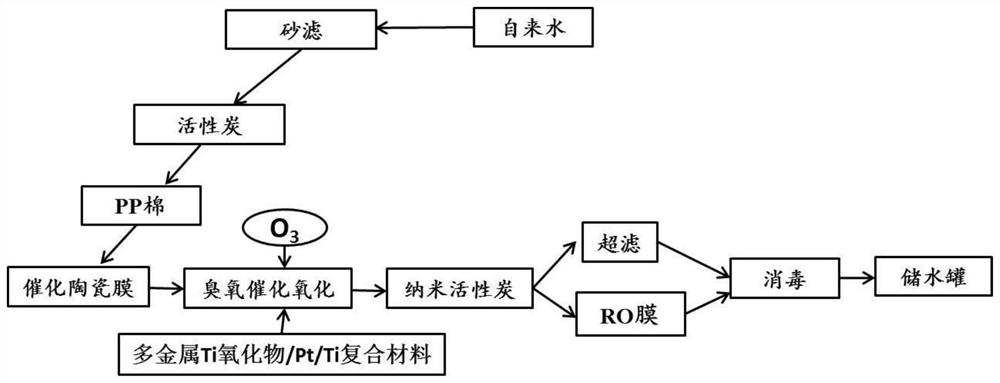

[0058] Catalytic oxidation combined membrane treatment technology is used to remove trace pollutants in tap water. The specific operation method is as follows:

[0059] Such as figure 1 As shown, the tap water is first filtered through sand filter, activated carbon and PP cotton in sequence, and then filtered by catalytic ceramic membrane. After filtering, it enters the sealed water tank for electrocatalytic combined ozone catalytic oxidation treatment. After being filtered by nanofiltration membrane and reverse osmosis filtration membrane respectively, the effluent of nanofiltration membrane and reverse osmosis filtration membrane are mixed according to the ratio of 1:3, and finally enter the water storage tank after being sterilized by ultraviolet light.

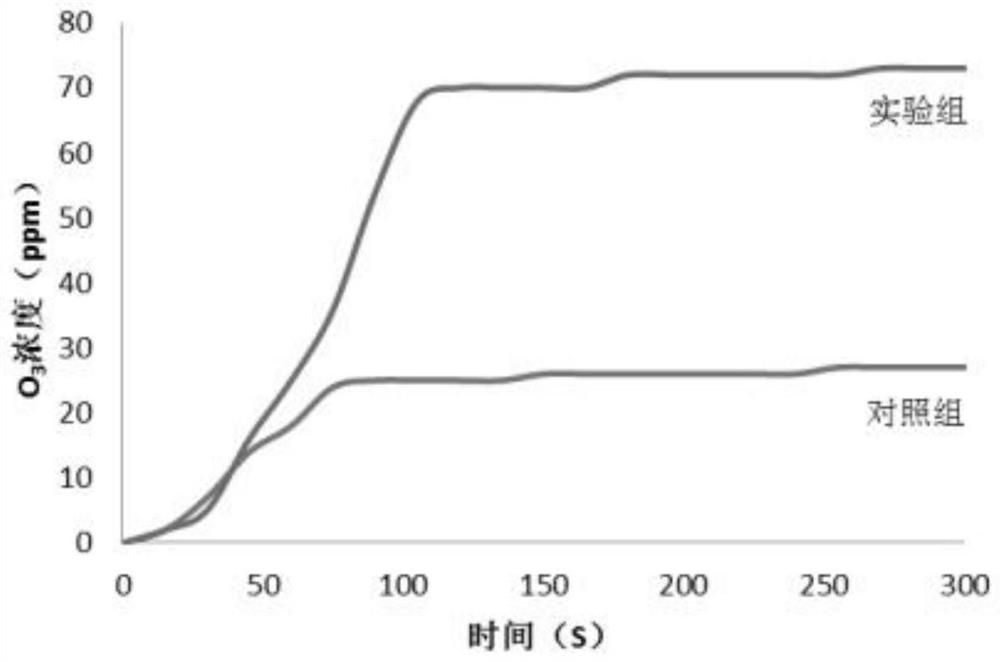

[0060] Wherein the sealed water tank contains a pair of electrodes, the anode is the multi-metal Ti composite oxide prepared in embodiment 1, the cathode is the Pt / Ti composite material prepared in embodiment 2, the ozone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap