Composite acrylic resin hot-melt adhesive and preparation method thereof

A technology of hot melt adhesive and acrylic resin, applied in the direction of adhesive type, ester copolymer adhesive, adhesive, etc. High strength, strong sticking force, stable storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 acrylic resin emulsion E-1

[0024] After mixing 145.0 g of butyl acrylate, 31.0 g of styrene, 6.0 g of hydroxyethyl acrylate, and 4.0 g of methacrylic acid at room temperature, they were added to a mixture containing 70.0 g of water and the emulsifier alkylphenol polyoxyethylene ether ammonium sulfate. 1.8 g and 0.8 g of allyloxy hydroxypropyl sodium sulfonate were pre-emulsified for 30 minutes to obtain pre-emulsified monomer A. Take 20.0 g of pre-emulsified monomer A as a seed, add it into a reaction flask, add 120.0 g of water, 0.3 g of ammonium sulfate of alkylphenol polyoxyethylene ether, 1.2 g of sodium allyloxy hydroxypropyl sulfonate and an initiator over Ammonium sulfate 0.4 g, react at 80-84°C for 30 minutes, then add the remaining pre-emulsified monomer A and ammonium persulfate 0.5g dropwise at 80-84°C (add in the form of solution, dissolve 0.5g ammonium persulfate into 5g of water), the dropwise addition was completed withi...

Embodiment 2,3

[0025] Embodiment 2, the preparation of 3 acrylic resin emulsion E-2, E-3

[0026] The proportions of raw materials used in the preparation of pre-emulsified monomer A are shown in Table 1. The experimental process was referred to in Example 1, and acrylic resin emulsions E-2 and E-3 with a solid content of about 40% were prepared.

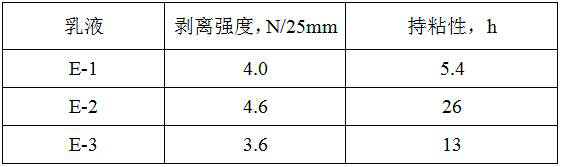

[0027] Table 1 Ratio of raw materials used in the preparation of pre-emulsion monomer A and the glass transition temperature of the obtained emulsion

[0028]

Embodiment 4

[0029] Example 4 Solid acrylic resin R 1 preparation of

[0030]Mix 60.0 g of styrene, 30.0 g of methylstyrene, 42.0 g of acrylic acid, 3.0 g of maleic anhydride, 118.0 g of butyl acrylate, and 5.0 g of di-tert-butyl peroxide at room temperature to obtain a mixture B. Add 48.0 g of solvent propylene glycol butyl ether into the reactor, heat to raise the temperature to 140-145°C, and gradually drop the mixture B into the reactor within 2 hours. After the addition, raise the temperature to 175°C and keep it for 60 minutes. Then reduce pressure (pressure 16-20 kpa) to distill off the solvent propylene glycol butyl ether, discharge while hot, and cool to room temperature to obtain solid acrylic resin R 1 , The softening point is 103°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com