Treatment method of landfill leachate

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve the problems of difficult treatment, high treatment cost, and high degree of harm, and achieve the effects of increasing the oxidation reaction rate, controlling the degradation rate, and improving the oxidation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

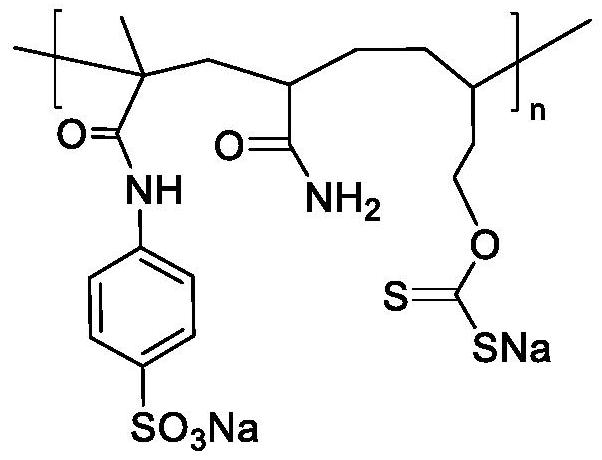

[0052] Preparation of modified anionic polyacrylamide:

[0053] (1) Add 0.01mol methacrylic acid, 0.01mol N,N-diisopropylcarbodiimide, 0.01mol triethylamine, and 60mL tetrahydrofuran into a three-necked flask in turn, stir for 40min, and heat under nitrogen atmosphere To 40°C, add 40 mL of tetrahydrofuran solution containing 0.01 mol of 4-aminobenzenesulfonate dropwise at a rate of 2 drops / second, stir and react for 12 hours, then filter the reaction solution, take the filter cake, wash it, and dry it in vacuum to obtain Benzenesulfonic acid monomer;

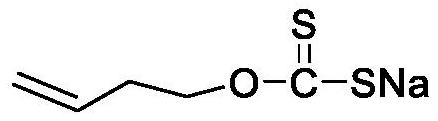

[0054] (2) After mixing 0.011mol 3-buten-1-ol and 50mL ethanol, stir evenly, then add 0.01mol sodium hydroxide, then raise the temperature to 30°C while stirring, add 0.01mol carbon disulfide dropwise, drop The acceleration is 3 drops / second. After the addition is complete, continue the constant temperature reaction for 4 hours, stop the reaction, wash with hexane several times, and dry to obtain the dithiocarboxy monomer;

[...

Embodiment 2

[0057] Preparation of modified anionic polyacrylamide:

[0058] (1) Add 0.015mol methacrylic acid, 0.015mol N,N-diisopropylcarbodiimide, 0.015mol triethylamine, and 120mL tetrahydrofuran into a three-necked flask in turn, stir for 40min, and heat under nitrogen atmosphere To 40°C, add 80 mL of tetrahydrofuran solution containing 0.01 mol of 4-aminobenzenesulfonate dropwise at a rate of 2 drops / second, stir and react for 12 hours, then filter the reaction solution, take the filter cake, wash it, and dry it in vacuum to obtain Benzenesulfonic acid monomer;

[0059] (2) After mixing 0.014mol 3-buten-1-ol and 90mL ethanol, stir evenly, then add 0.01mol sodium hydroxide, then raise the temperature to 30°C while stirring, add 0.01mol carbon disulfide dropwise, drop The acceleration is 5 drops / second. After the addition is complete, continue the constant temperature reaction for 4 hours, stop the reaction, wash with hexane several times, and dry to obtain the dithiocarboxy monomer; ...

Embodiment 3

[0062] The biochemical effluent of landfill leachate was selected as the treatment object, and the indicators of the biochemical effluent of the landfill leachate are shown in Table 1:

[0063] Table 1

[0064]

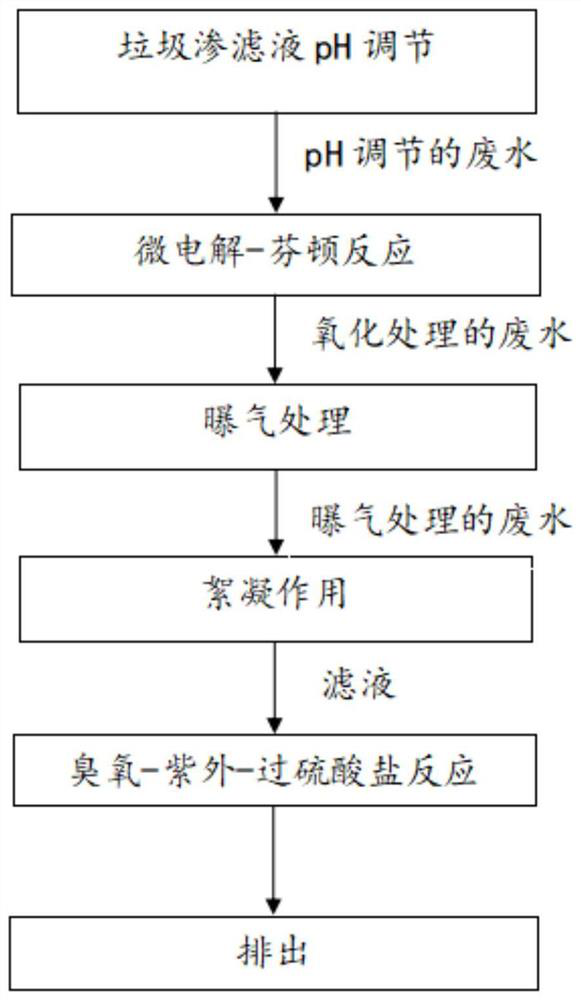

[0065] See processing steps figure 1 As shown, the processing parameters are as shown in Table 2:

[0066] Table 2

[0067]

[0068]

[0069] The indicators of the discharged water are shown in Table 3.

[0070] table 3

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com