Method for fabrication of hybrid solid electrolyte membrane and all-solid-state lithium battery

A solid electrolyte membrane, composite technology, applied in non-aqueous electrolyte batteries, solid electrolytes, electrolytes, etc., can solve problems such as combustion, poor battery performance, and safety impact of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] "La 3 Zr 2 Ga 0.3 (OH) x,x=17.9 Hydroxide Precursor Preparation》

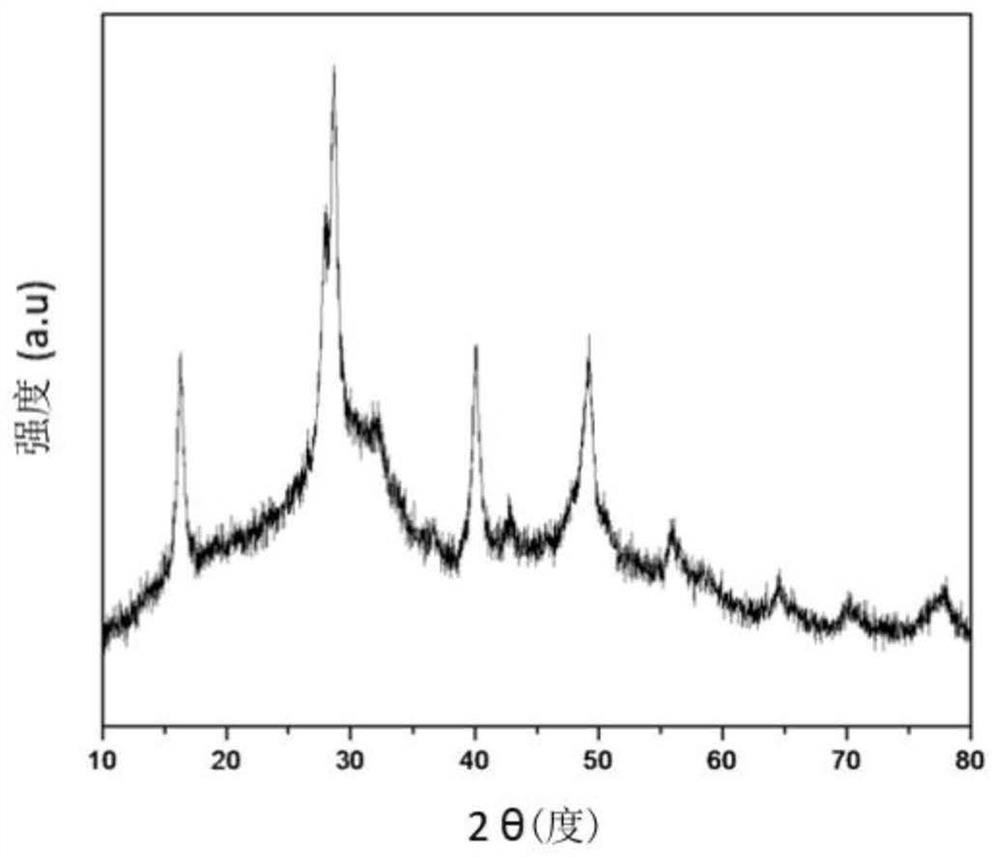

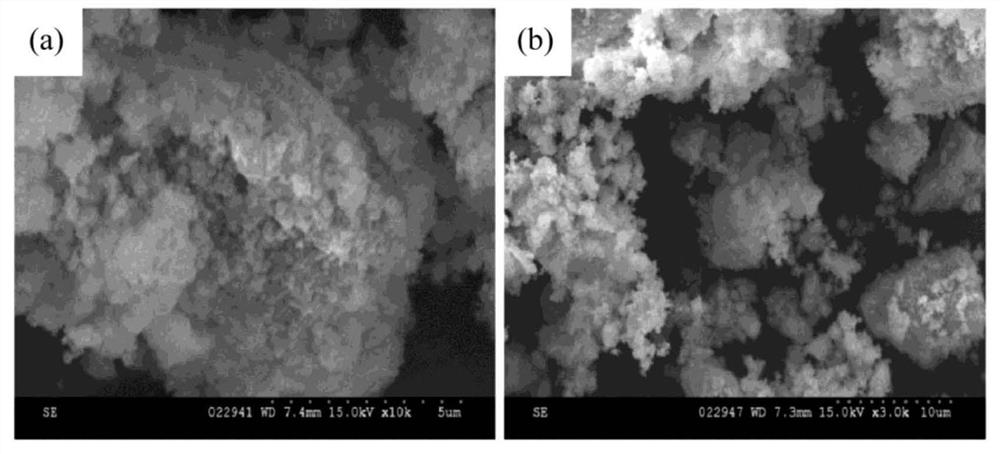

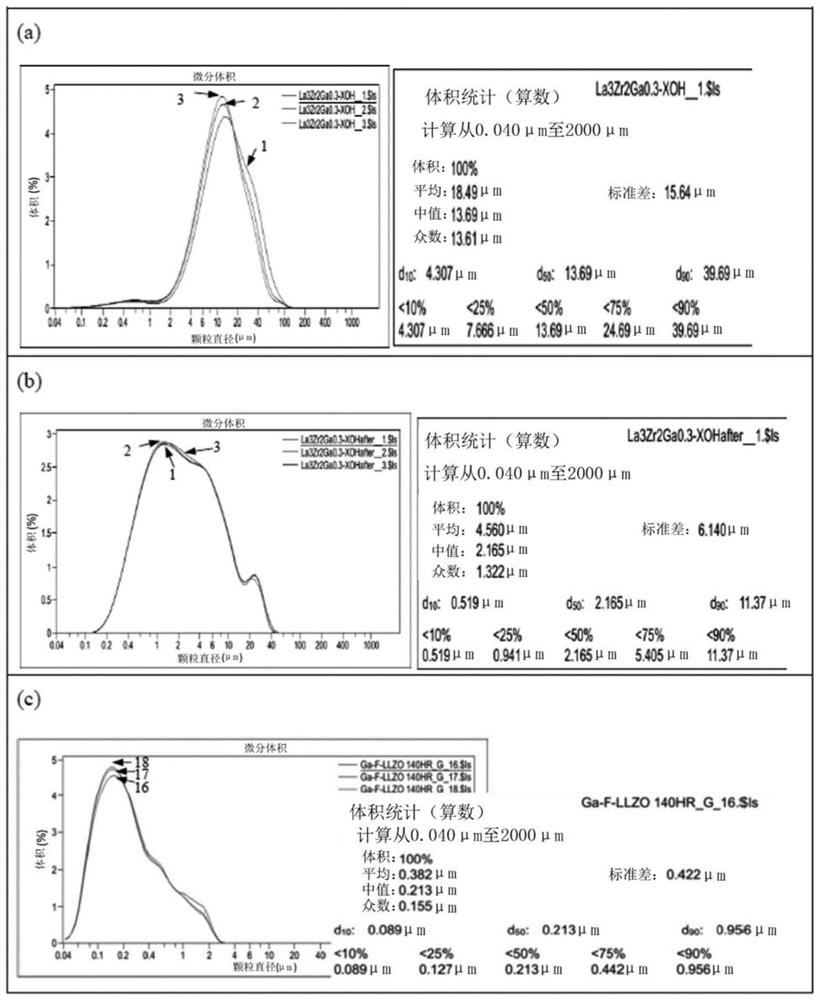

[0070] Compared with the traditional batch reactor (Batch reactor) preparation method, TFR produces a greater mixing force through the flow principle of Taylor fluid, which is about 7 times that of the traditional one, so it can be processed in a shorter reaction time (about 1 / 8 reaction time; faster mass transfer speed: 3.3vs.1.0m s -1 ) to obtain a smaller particle size distribution, about 1 / 2 the size of the traditional, pure cubic phase (Cubic phase) hydroxide precursor and high yield (reactor volume: 1 ~ 300L). Therefore, utilize TFR reactor to prepare La in the present invention 3 Zr 2 Ga 0.3 (OH) 17.9 , metal hydroxide precursors.

[0071] LaZrGa(OH) x One of the specific implementations of the preparation method of the metal hydroxide precursor is as follows:

[0072] First, weigh the metal salt powder to prepare 2M La(NO 3 ) 3 ·6H 2 O, ZrOCl 2 ·8H 2 O and Ga(NO 3 ) 3 The metal...

Embodiment 2

[0074] "Synthesis of ion-doped Ga-F-LLZO (i.e. Li 5.9 Ga 0.3 La 3 Zr 2 f 0.2 o 11.8 ) All-solid lithium ion conductive material》

[0075] The ion-doped Ga-F-LLZO all-solid-state lithium ion conductive material formed by fluorine doping (the metering is 0.2, using LiF as the ion doping source) is obtained by drying the La 3 Zr 2 Ga 0.3 (OH) 17.9 Metal hydroxide precursor, 10% excess LiOH.H 2 O (that is, the molar ratio is LaZrGa(OH) x : LiOH.H 2 O=1:6, in order to compensate for the subsequent loss of lithium in high temperature environment due to calcination heat treatment) and LiF is placed in a ball mill jar filled with 99% methanol solvent (using zirconia balls, the weight ratio of the mixture and the balls is 1:10), and through a planetary ball mill (Planetary Ball Mill PM 200, Retsch, Germany), the rotation speed is 400rpm, and the grinding and mixing time is about 20 minutes. After the grinding is completed, the grinding balls are first taken out of the ball...

Embodiment 3

[0079] "Preparation of Freestanding Double-layer Composite Solid Electrolyte (Bi-HSE) Membrane"

[0080] Independent double-layer composite solid electrolyte membrane, i.e. Ga-F-LLZO@PVDF+PAN / LiTFSI / SN / / Ga-F-LLZO@PVDF+PAN / LiTFSI / SN film of double-layer structure (in the present invention, The substances contained in the same layer of film are separated by / , and the different layers of film are separated by / / , and the position is arranged from top to bottom as "the first layer / / the second layer / / the third layer") One of the specific implementations of the method is as follows:

[0081] The independent double-layer composite solid electrolyte membrane with the function of conducting lithium ions is composed of polyvinylidene fluoride (PVDF) polymer, polyacrylonitrile (PAN) polymer, lithium bistrifluoromethanesulfonimide (LiTFSI) lithium salt , succinonitrile (SN) plasticizer and the ion-doped Ga-F-LLZO all-solid lithium ion conductive material of Example 2. During the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com