Corner connecting material for bonding ethylene-propylene-diene monomer rubber, and preparation method thereof

A technology of EPDM rubber and corner material, which is applied in the field of corner material, and can solve the problem of weak bonding of thin and narrow edges of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Above-mentioned a kind of preparation method that is used for bonding the corner material of EPDM rubber, comprises the following steps:

[0039] 1) Add naphthenic oil to ultra-high molecular weight SEBS for oil extension, and the standing time after oil extension is 5-10h;

[0040] 2) Weigh polypropylene and EPDM rubber into the SEBS filled with oil in step 1), mix in a low mixer for 5-10min, and mix evenly;

[0041] 3) Weigh erucamide, silicone masterbatch, antioxidant and black masterbatch and add to the mixture in step 2), mix in a low mixer for 10-20min, and mix thoroughly;

[0042] 4) Weigh talcum powder and add it to the mixture in step 3), mix it in a low mixer for 10-20mim, and mix thoroughly;

[0043] 5) Add the mixed material in the above step 4) into the twin-screw by feeding, melt in the twin-screw and extrude through the machine head. Granulate in the granulator to obtain the product, wherein the temperature setting of the twin-screw zone is 60°C, 80°C, ...

Embodiment 1

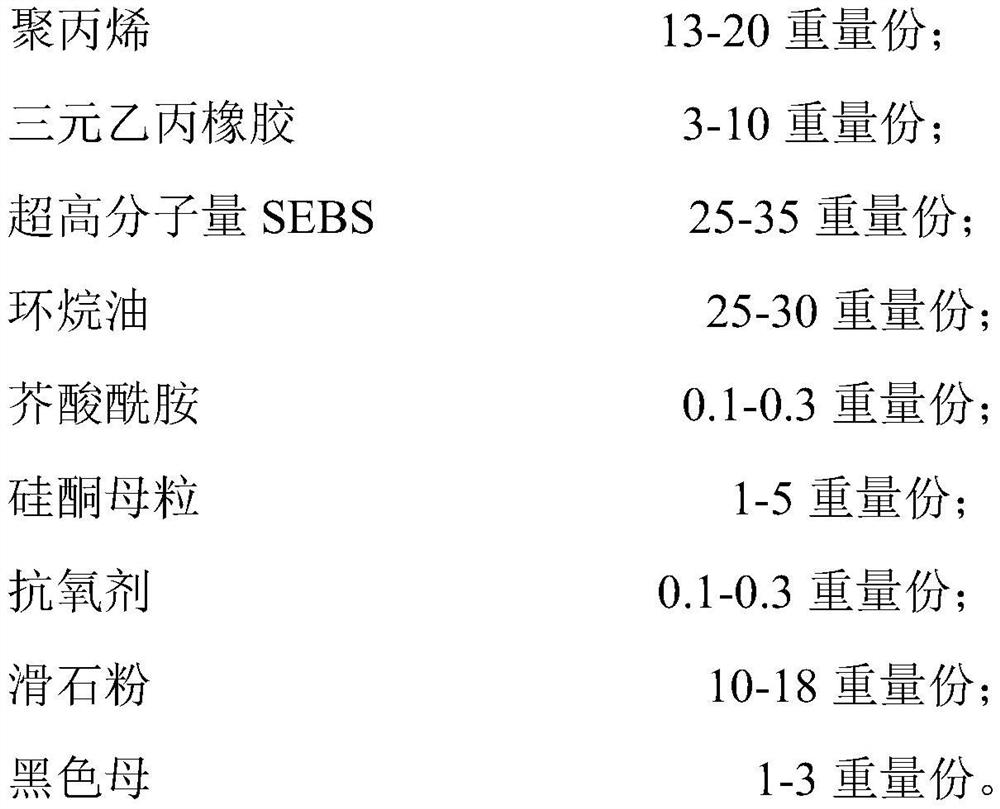

[0046] A kind of joint material that is used for bonding EPDM of ternary ethylene propylene rubber, by weight, comprises the following components:

[0047]

[0048]

[0049] The above-mentioned preparation method of the thermoplastic elastomer corner material for bonding EPDM rubber may further comprise the steps:

[0050] 1) Add naphthenic oil to ultra-high molecular weight SEBS for oil extension, and the standing time after oil extension is 10h;

[0051]2) Weighing polypropylene and EPDM rubber into the SEBS filled with oil in step 1), mixing in a low mixer for 8 minutes, and mixing evenly;

[0052] 3) Weigh erucamide, silicone masterbatch, antioxidant and black masterbatch and add to the mixture in step 2), mix in a low mixer for 10 minutes, and mix thoroughly;

[0053] 4) Weigh the filler and add it to the mixture in step 3), mix it in a low mixer for 10 minutes, and mix thoroughly;

[0054] 5) Add the mixed material in the above step 4) into the twin-screw by feed...

Embodiment 2

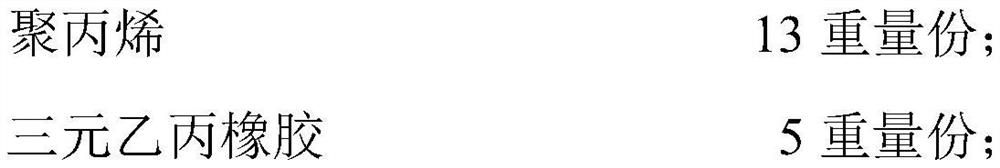

[0056] A kind of joint material for bonding EPDM rubber, by weight, includes the following components:

[0057]

[0058]

[0059] The preparation method of the scrap material of the present embodiment 2 is the same as that of the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com