Integrated forming device for silicone rubber double-form tube

A molding device, silicone rubber technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of patient safety, low bonding strength, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

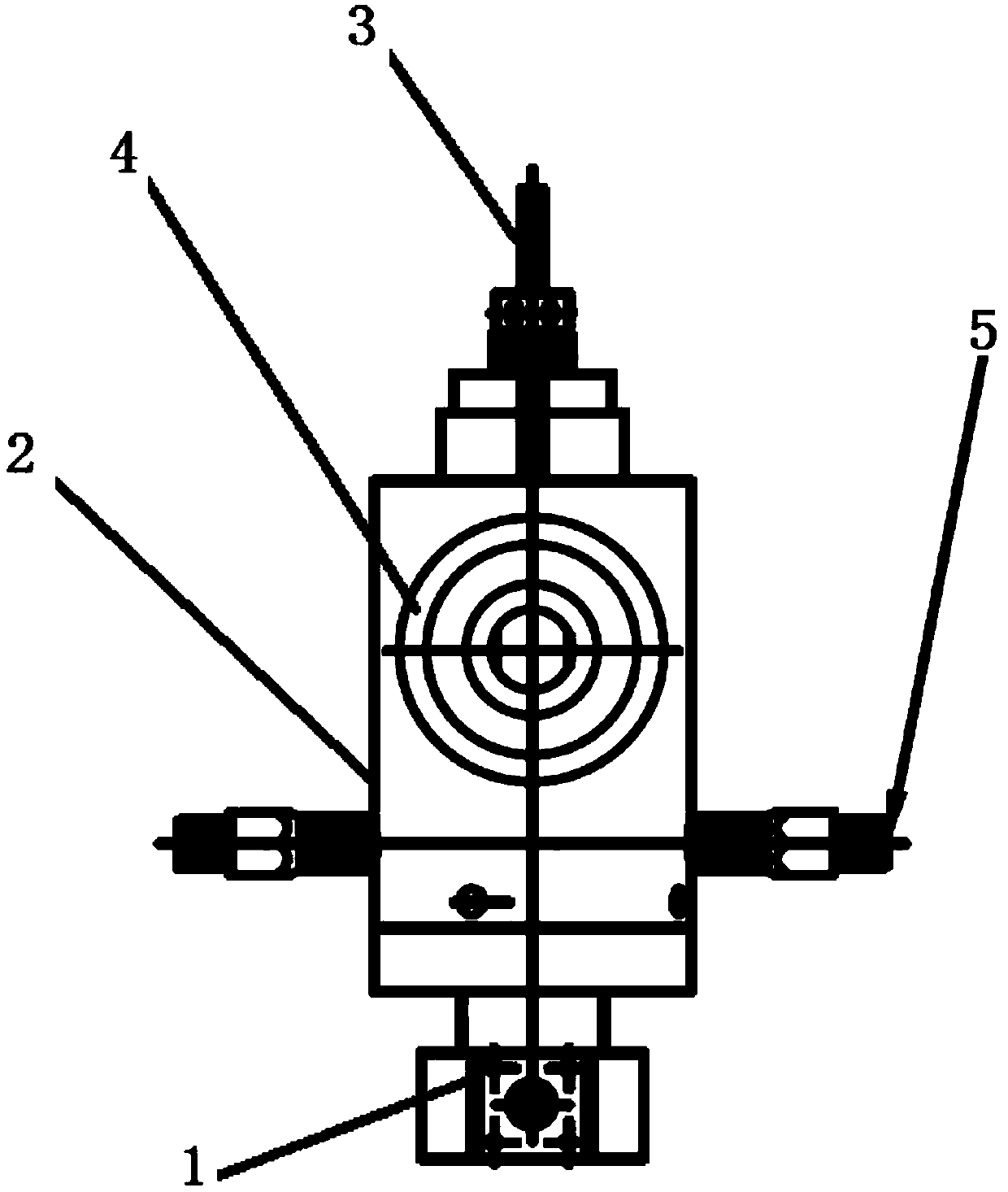

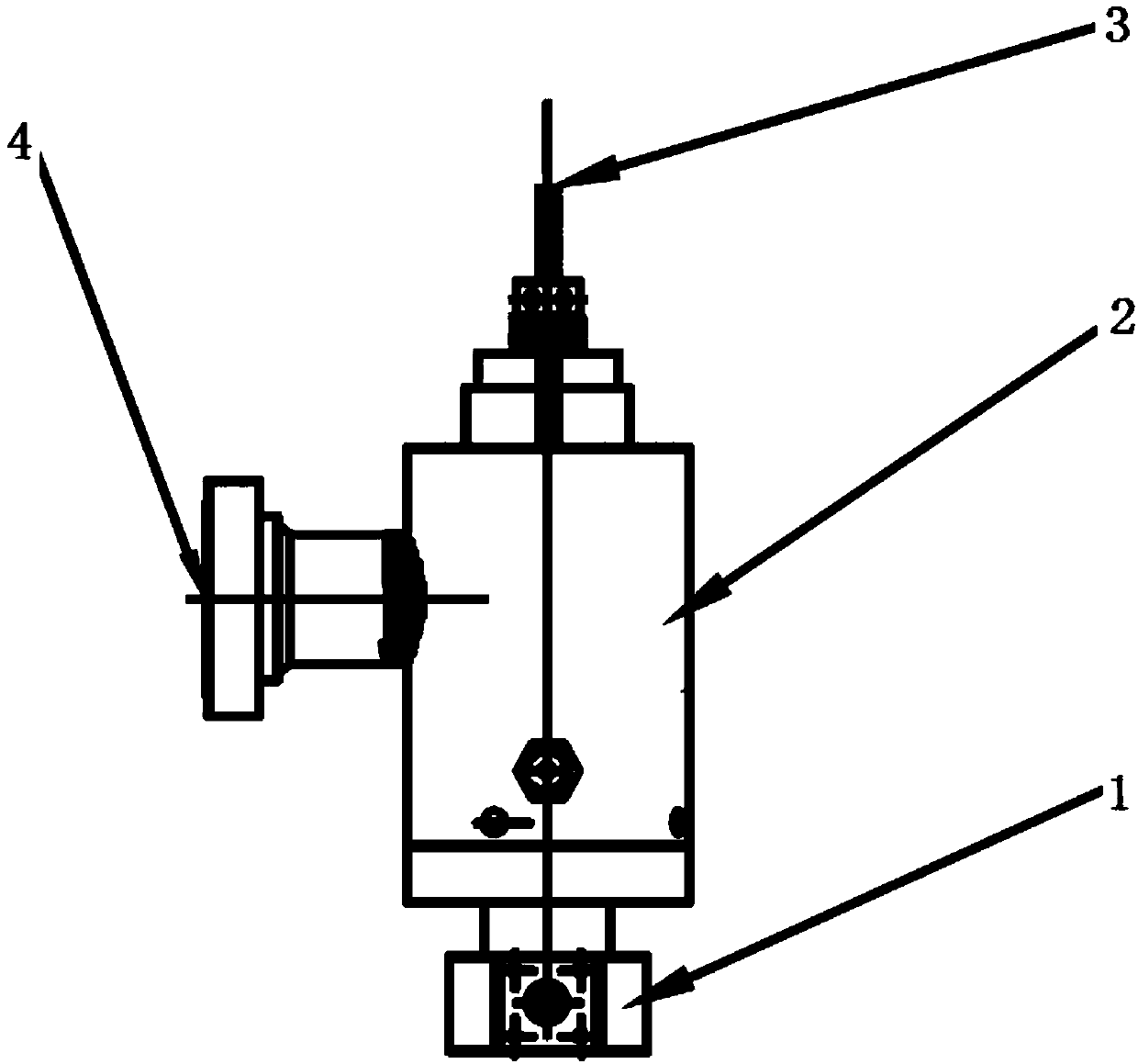

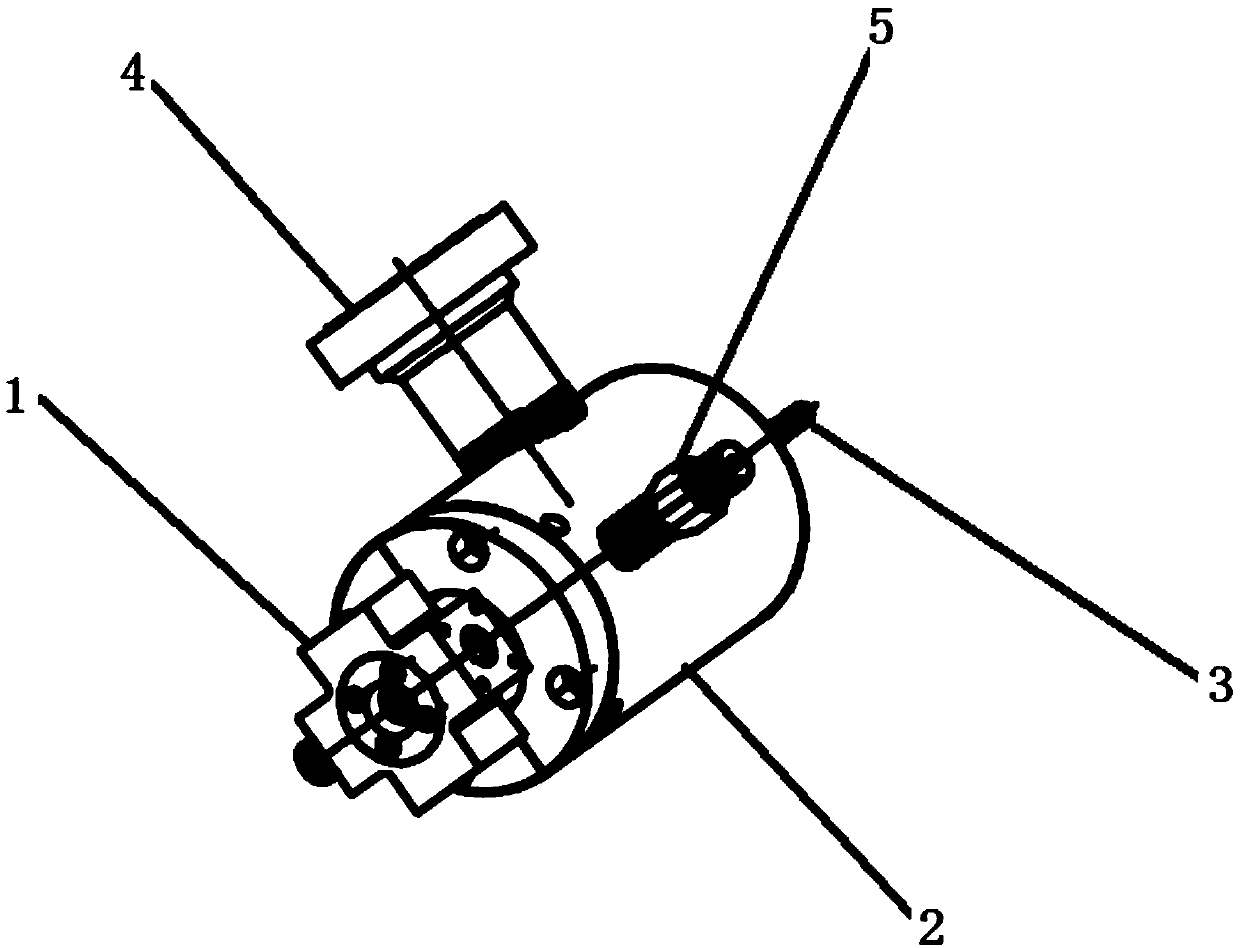

[0029] see figure 1 It can be seen that a silicone rubber double-shaped tube integrated molding device of the present invention includes an integrated molding device body 2; the outer body 2 of the integrated molding device is provided with a casing, and a composite mold A8 and a composite mold B11 are arranged in the casing. The side is provided with a main material channel 4 and an auxiliary material channel 5. The composite mold A8 is formed by a combination of a cross 6 and a core mold 7, and the composite mold B11 is formed by a combination of a circular die 9 and four injection needles 10. One end of the integral molding device body 2 is provided with a connecting rod 3, and the other end of the integral molding device body 2 is provided with a fixed seat 1 of the composite mold B, the composite mold A8 is arranged on the fixed seat of the composite mold A8, and the connecting rod 3 is connected to the composite mold A8 and Composite mold B11 has two auxiliary material c...

specific Embodiment 2

[0030] A method for processing a silicone rubber double-shaped tube integrated molding device, characterized in the integrated molding method:

[0031] 1) Forming of cross strips: Silicon rubber is extruded through the main material channel 4 and auxiliary material channel 5, and the connecting rod 3 drives the cross 6 to move upwards and separate from the composite mold A8 to form the cross strips. The die 9 of the silicone rubber round tube is Circular, 4 quarter arc blocks on the block are compounded into a cross flower shape, and the four needles 10 move radially to the axis and cooperate with the core mold 7 to form the opening of the cross flower strip. The two actions are carried out at the same time. At this moment, the rubber material flows through the space of the forming device to form a cross flower strip;

[0032]2) Forming of circular tube: The circular tube is jointly molded by the composite mold A8 and the composite mold B11, and the silicone rubber flows throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com