Poly 3,4-ethylenedioxythiophene/polyethyleneimine modified waterborne epoxy emulsion, preparation method thereof and anticorrosive coating

A technology of ethylenedioxythiophene and water-based epoxy emulsion, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor solubility of PEDOT, poor dispersion of PEDOT, and affecting the application of PEDOT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The invention provides a kind of preparation method of the water-based epoxy emulsion of PEDOT / PEI modification, comprises the steps:

[0051] S101: Mix EDOT monomers and solvents, then add an initiator, stir and react, and prepare a PEDOT dispersion.

[0052] Further, in step S101, the mass ratio of EDOT, solvent and initiator is (1-4):(20-80):(1-2).

[0053] Further, in step S101, the initiator is selected from one or more of ammonium persulfate, sodium persulfate and potassium persulfate.

[0054] Further, in step S101, the solvent is a mixture of alcohol and water; the alcohol is selected from one or more of methanol, ethanol and propanol.

[0055] Further, in step S101, the time for the stirring reaction is 1 hour to 10 hours, the temperature of the stirring reaction is 20-100° C., and further, the reaction temperature is 25° C.

[0056] Further, in step S101, the particle size of PEDOT in the PEDOT dispersion is 30-100 nm.

[0057] In the present invention, the...

Embodiment 1

[0109] This example provides a water-based epoxy emulsion modified by poly(3,4-ethylenedioxythiophene / polyethyleneimine) and its preparation method. The steps are as follows:

[0110] (1) Preparation of PEDOT dispersion

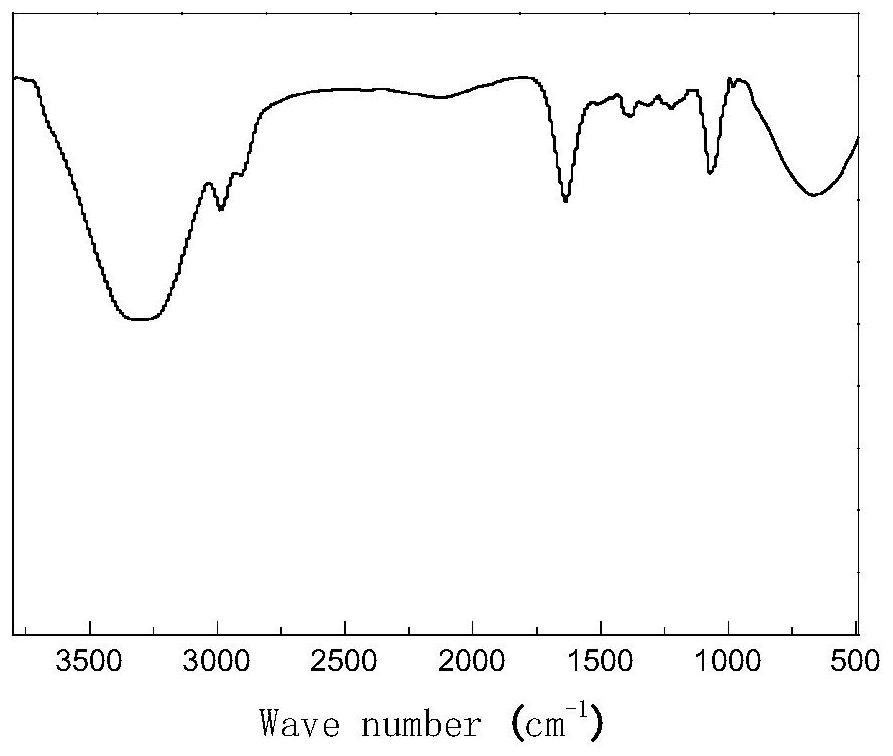

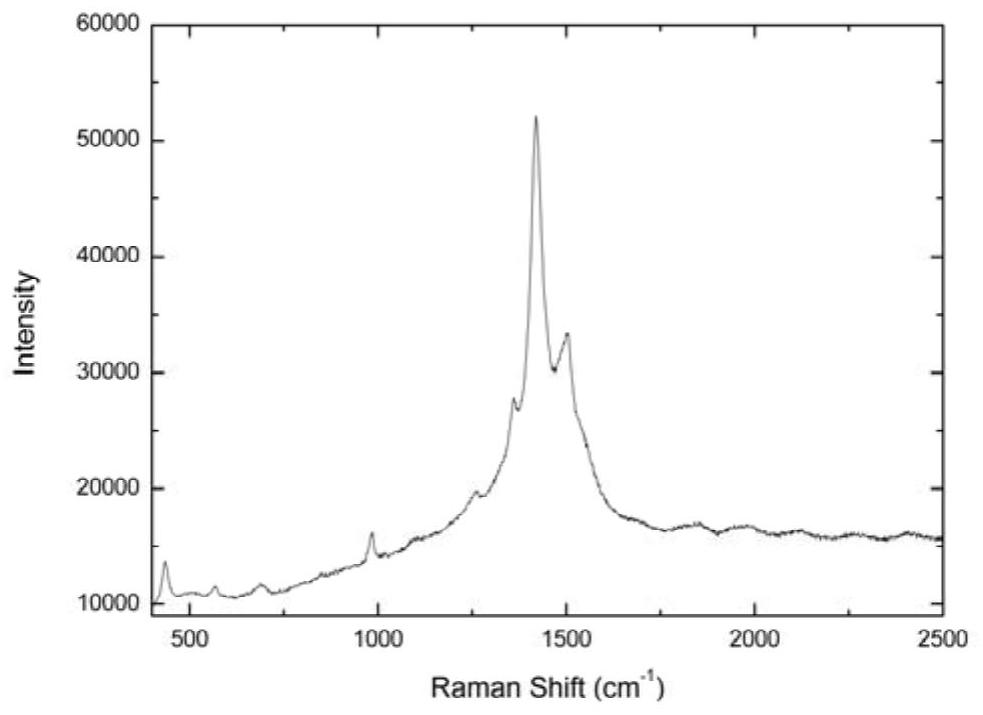

[0111] First dissolve 2g of EDOT monomer in a mixed solution of 20ml of alcohol and 20ml of water, then add 0.5g of ammonium persulfate, stir thoroughly, and after stirring for 1 hour, prepare a PEDOT dispersion. The infrared spectrum of the prepared PEDOT is as follows figure 1 As shown, the Raman spectrum of PEDOT nanoparticles is shown in figure 2 shown.

[0112] combine figure 1 and figure 2 ,Depend on figure 1 In the infrared spectrum of PEDOT, it can be seen that the wavelength is 721 -1 , 862 -1 、995cm -1 is the characteristic peak of the C-S stretching vibration in the thiophene ring; the wavelength is 1062 -1 、1123 -1 、1165cm -1 is the absorption peak of C-O-C bending vibration in PEDOT; the wavelength is 1265 -1 、1499cm -1 are the char...

Embodiment 2

[0119] The present embodiment provides a kind of anticorrosion paint (primer) and preparation method thereof, and the steps are as follows:

[0120] (1) Preparation of component A

[0121] 450g of PEDOT / PEI modified water-based epoxy emulsion prepared in Example 1, 10g of BYK-154 wetting and dispersing agent, 5g of BYK-028 defoamer, 5g of BYK-381 leveling agent, 150g of micaceous iron oxide ash, trimer Aluminum phosphate 80g, zinc phosphate 80g, 3000 mesh barium sulfate 100g, Pangel B40 hydrated magnesium silicate 10g, A200 fumed silica 10g, purified water 100g, mix all raw materials, stir and disperse on a high-speed disperser for 20-30min, then add Grinding with a sand mill, the particle size of the filler in the mixture after grinding is 25-30 μm, filtering and packing separately to obtain component A.

[0122] (2) Preparation of component B

[0123] Divide 200 g of polyetheramine BASF BS-725 water-based epoxy curing agent into subpackages to obtain component B.

[0124]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com