Solid-state electrolyte and solid-state battery containing same

A solid-state electrolyte and solid-state battery technology, which is applied in the direction of non-aqueous electrolyte batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve problems that affect the stable energy output and cycle life of solid-state batteries, interface damage, poor contact, etc., and achieve excellent chain segments Mobility, good interface performance, and the effect of inhibiting electrode expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

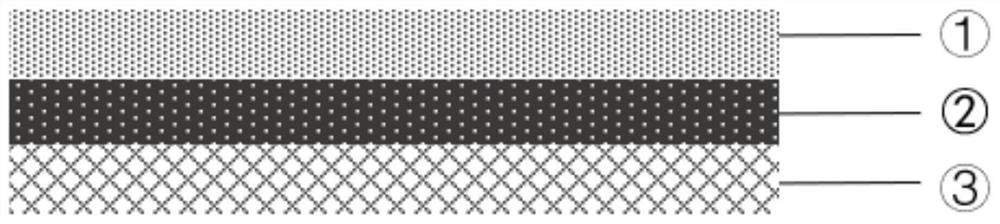

Image

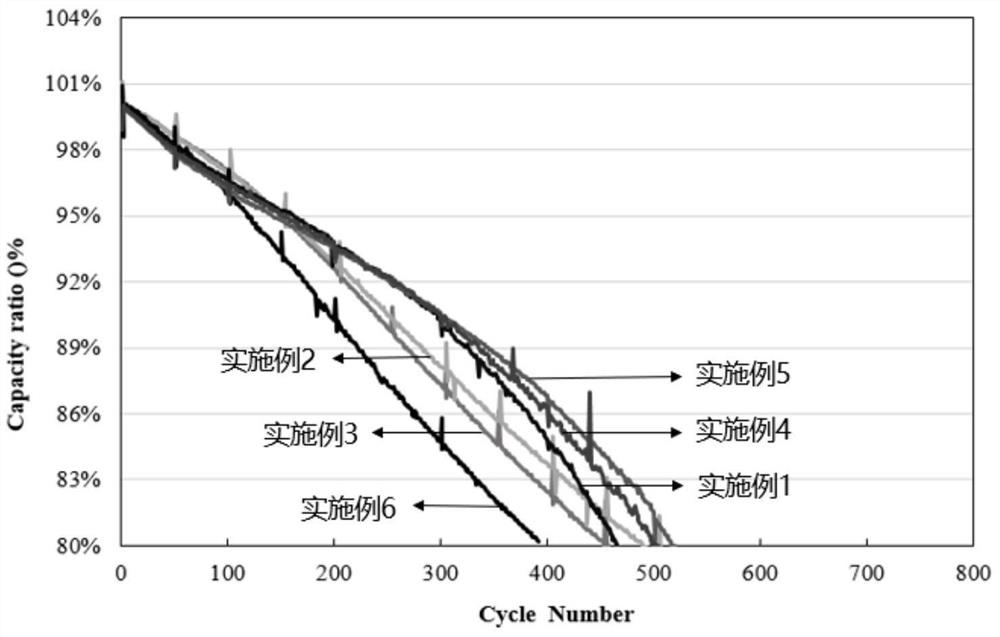

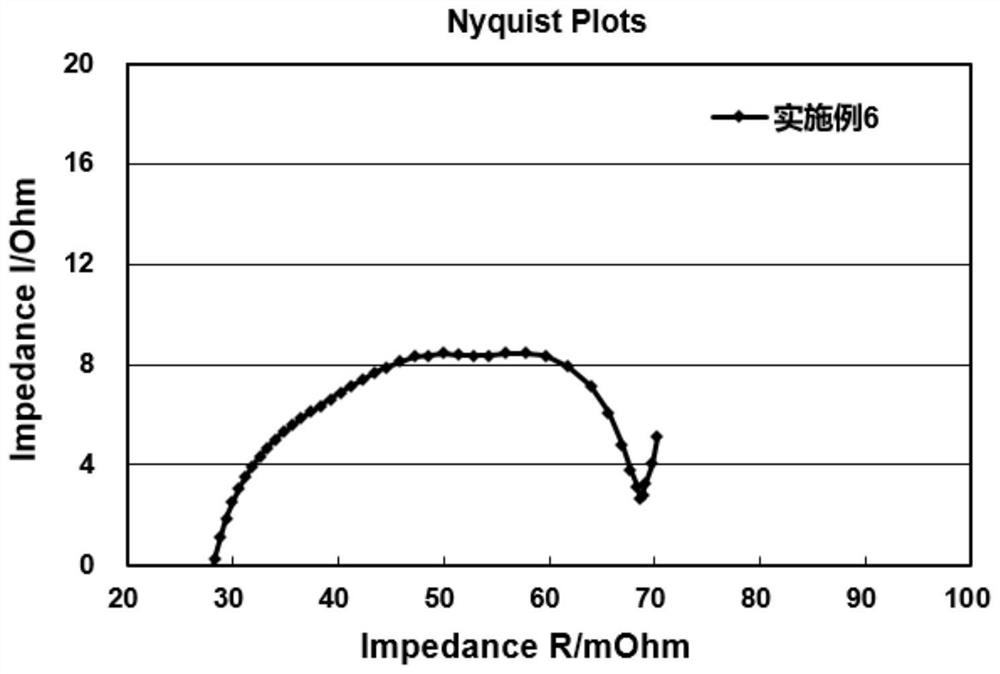

Examples

preparation example Construction

[0074] The present invention also provides a preparation method for the above-mentioned polymer, which includes the following steps: obtaining the polymer by polymerizing a composition comprising the following components: polyester polyol, polysiloxane, electrolyte salt and diisocyanate.

[0075] According to the present invention, additives are further included in the composition.

[0076] According to the present invention, a chain extender is further included in the composition.

[0077] According to the present invention, metal chlorides are further included in the composition.

[0078]According to the present invention, the composition further includes a fast ion conductor.

[0079] According to the present invention, the definition and content of each component in the composition are as described above.

[0080] According to the invention, the polymerization is carried out in a solvent. Exemplarily, the solvent includes but not limited to acetonitrile (abbreviated as ...

Embodiment 1

[0163] Preparation of solid electrolyte:

[0164] (1) Dissolve 26.8g of polycaprolactone diol and 11.2g of hydroxyl-terminated polytrimethicone in ACN to form a solution with a solid content of 13%, and fully stir at 45°C for 3 hours under argon to form a precursor solution A;

[0165] (2) Add 4.4g of diphenylmethane diisocyanate and 1.2g of 4,4'-bipyridine to the above precursor solution A, and continue heating and stirring at 45°C for 1h in an argon atmosphere to form precursor solution B;

[0166] (3) Add 0.5g of 1,4-butanediol (BDO) and 6.7g of LiTFSI into the above-mentioned precursor solution B, and continue to fully stir for 6 hours to form a uniform precursor solution C;

[0167] (4) Dissolve 3 g of zinc chloride in ACN and fully stir to form a homogeneous solution, add it to the above precursor solution C, and fully mix and stir at 500 rpm for 4 hours at room temperature;

[0168] (5) Pour the obtained product into a polytetrafluoroethylene mold plate, heat at 60°C ...

Embodiment 2

[0175] Preparation of solid electrolyte membrane:

[0176] (1) Dissolve 14.3g of polycarbonate diol and 5.4g of hydroxyl-terminated polydimethylsiloxane in DMAC to form a solution with a solid content of 10%, and fully stir at 50°C for 4h under argon to form a precursor solution A ;

[0177] (2) Add 2.1 g of dicyclohexylmethane diisocyanate and 0.7 g of 2,2'-bipyridine-4,4'-dimethanol to the above precursor solution A, and continue heating and stirring at 50°C for 3 hours in an argon atmosphere to form a Precursor B;

[0178] (3) Mix 0.21g of diethylene glycol, 3.9g of LiODFB, 1gLi 6.6 La 3 Zr 1.6 Ta 0.4 o 12 Add to the above precursor solution B, continue to fully stir for 5 hours to evenly form precursor solution C;

[0179] (4) Dissolve 1.3g of zinc chloride in ethanol and fully stir to form a homogeneous solution, add it to the above-mentioned precursor solution C, and fully mix and stir at 600 rpm for 4 hours at room temperature;

[0180] (5) Scrape-coat the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com