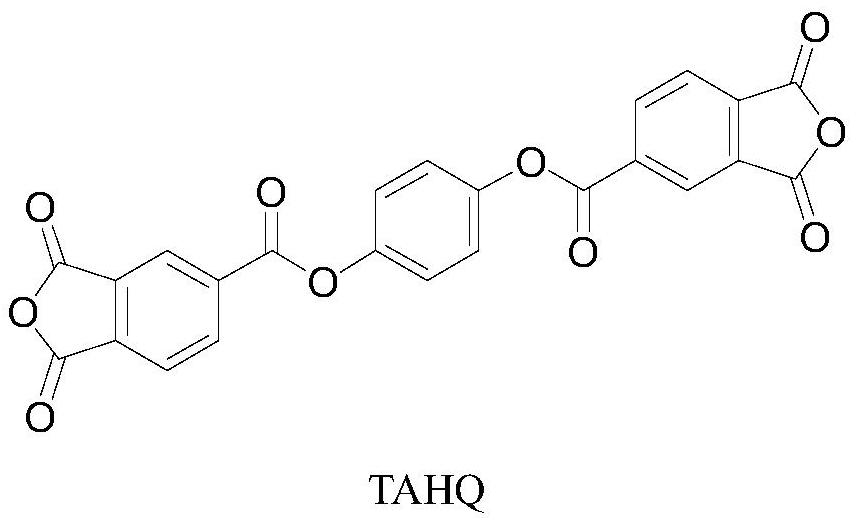

Thermoplastic polyimide resin composite film with low dielectric property and preparation method thereof

A technology of polyimide resin and composite film, which is applied in the field of thermoplastic polyimide resin composite film and its preparation, can solve the influence of polyimide matrix mechanical properties and heat resistance performance, and reduce polyimide film Difficult to control the electrical constant and the uniformity of inorganic fillers, etc., to achieve good melt processability, increase and reduce water absorption, and improve the effect of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 8.0058g (0.025mol) 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl monomer, 9.6105g (0.025mol) 9,9-bis( 4-Amino-3-fluorophenyl) fluorene monomer, 180mL N,N-dimethylacetamide, stirring at room temperature under nitrogen protection, after the diamine monomer is completely dissolved, add 4.5833g (0.01mol) p- Phenyl-bis trimellitate dianhydride monomer: 20.7155g (0.0398mol) bisphenol A type diether dianhydride monomer, 50mL N,N-dimethylacetamide; react at room temperature for 22 hours, add 0.1185 g (0.0008mol) phthalic anhydride monomer, and react at room temperature for 4 hours to obtain a polyamic acid solution.

[0056] Add 34ml of a mixed solution of acetic anhydride and pyridine (30mL of acetic anhydride and 4mL of pyridine), continue the reaction at room temperature for 6 hours, slowly pour the reaction solution into 3L of deionized water to precipitate, filter, and wash the obtained filter cake twice with deionized water , and then dried in a vacuum oven at 120° C....

Embodiment 2

[0059] Add 336.23g (1mol) 2,2'-bis(trifluoromethyl)-4,4'-diaminophenylether monomer into a dry and clean 50L double-layer glass reactor, 1567.98g (4mol) 9, 9-bis(4-aminophenyl)fluorene monomer, 17L N,N-dimethylacetamide, stirring at room temperature under the protection of nitrogen, after the diamine monomer is completely dissolved, slowly add 458.33g (1mol) p- Phenyl-bis trimellitate dianhydride monomer: 1601.19g (3.98mol) 4,4'-triphenylene ether tetracarboxylic dianhydride monomer, 1L N,N-dimethylacetamide; normal temperature reaction After 18 hours, 11.85 g (0.08 mol) of phthalic anhydride monomer was added and reacted at room temperature for 4 hours to obtain a polyamic acid solution.

[0060] Add 2.83L of a mixed solution of acetic anhydride and pyridine (2.04L of acetic anhydride, 0.79L of pyridine), continue the reaction at room temperature for 6 hours, dilute the reaction solution with 54L of N,N-dimethylacetamide and slowly pour it into 360L Precipitated in deionized...

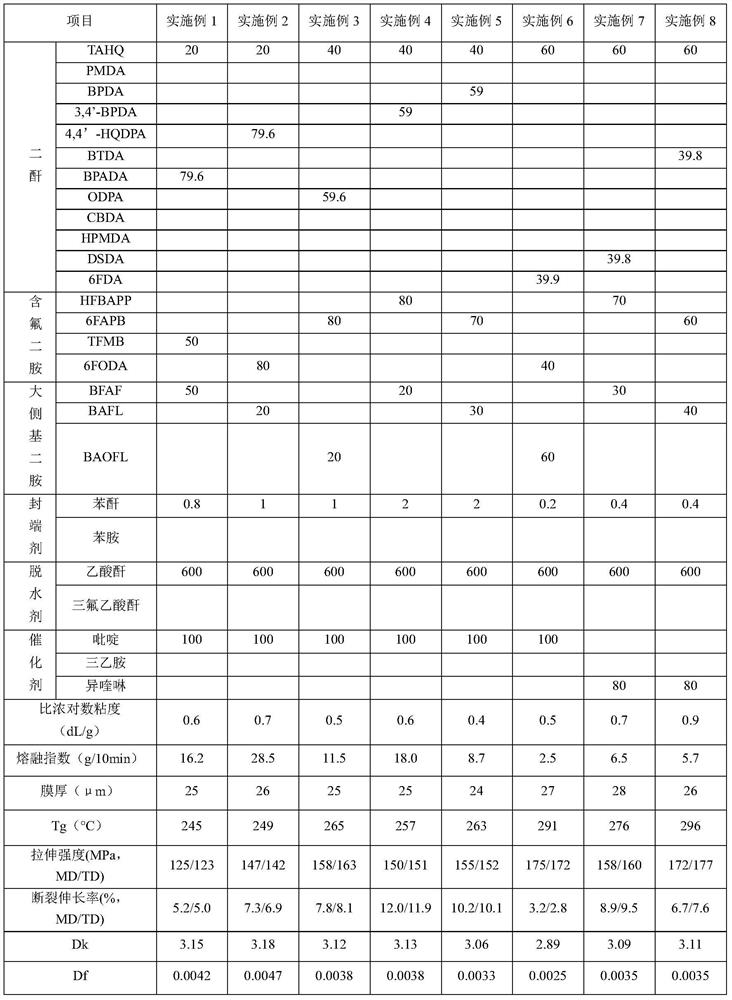

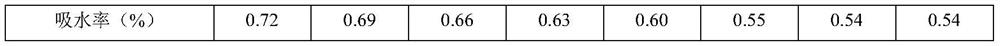

Embodiment 3~14 and comparative example 1~2

[0063] Replace the diamine and dianhydride with the ratios shown in the following Table 1 and Table 2 to carry out resin polymerization respectively, and conduct heat preservation reaction at 0-50°C for 1h-24h polymerization to obtain polyamic acid with a solid content of 10-30% solution.

[0064] Then, in the same manner as in Example 1, a 25 μm thick polyimide film was prepared.

[0065] For the polyimide films obtained in Examples and Comparative Examples, the properties of the prepared polyimide films were measured according to the above-mentioned method, and the results are summarized in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com