Blue-light perovskite thin film, preparation thereof, and inverted quasi-two-dimensional blue-light perovskite light-emitting diode

A light-emitting diode and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of spectral red shift, poor stability, and low device performance, and achieve improved grain refinement, improved Thin film morphology, the effect of suppressing the blue shift of the spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

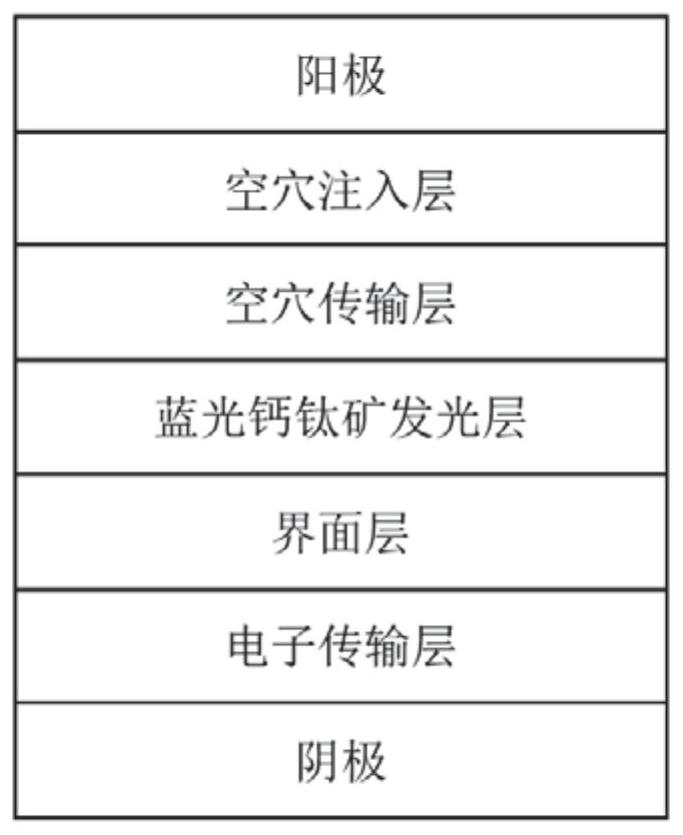

[0061] The device structure of the flip-chip quasi-two-dimensional blue light perovskite light-emitting diode of this embodiment is: cathode (ITO) / electron transport layer (ZnO) / interface layer (PEIE) / blue light perovskite light emission with a peak wavelength of emission spectrum of 490nm layer / hole transport layer (TFB) / hole injection layer (MoO 3 ) / anode (A1).

[0062] The preparation process is as follows:

[0063] a. Prepare the solution: use DMSO to sequentially dissolve PbBr 2 , F-PEABr (p-fluorophenethylamine bromide, F-Ph-CH 2 CH 2 NH 3 Br, 1,4 substitution on the benzene ring) and CsBr are formulated into a solution to obtain a blue light perovskite precursor solution; PbBr in the blue light perovskite precursor solution 2 The concentration of F-PEABr is 0.2mmol / mL, the concentration of F-PEABr is 0.25mmol / mL, and the concentration of CsBr is 0.1mmol / mL;

[0064] b. O 2 -Plasma treatment to improve wettability on ITO, transfer substrate into N 2 In the glove ...

Embodiment 2

[0071] The device structure of the present embodiment is: cathode (ITO) / electron transport layer (ZnO) / interface layer (PEIE) / blue light perovskite light-emitting layer / hole transport layer (TFB) / hole with emission spectrum peak wavelength of 488nm Injection layer (MoO 3 ) / anode (Al). The blue-light perovskite light-emitting layer is the blue-light perovskite thin film.

[0072] The preparation process is as follows:

[0073] a. Prepare the solution: use DMSO to sequentially dissolve PbBr 2 , phenylbutylammonium bromide (Ph-CH 2 CH 2 CH 2 CH 2 NH 3 Br) and CsBr are formulated into a solution to obtain a blue-light perovskite precursor solution; PbBr in the blue-light perovskite precursor solution 2 The concentration of CsBr is 0.2mmol / mL, the concentration of phenylbutylammonium bromide is 0.2mmol / mL, and the concentration of CsBr is 0.1mmol / mL;

[0074] b. Before spin-coating the electron transport layer (ZnO), O 2 -Plasma treatment to improve wettability on ITO, tr...

Embodiment 3

[0081] The device structure of the present embodiment is: cathode (ITO) / electron transport layer (ZnO) / interface layer (PEIE) / blue light perovskite light-emitting layer / hole transport layer (TFB) / hole with emission spectrum peak wavelength of 492nm Injection layer (MoO 3 ) / anode (Al).

[0082] The preparation process is as follows:

[0083] a. Prepare the solution: use DMSO to sequentially dissolve PbBr 2 , F-PEABr (p-fluorophenethylamine bromide, F-Ph-CH 2 CH 2 NH 3 Br, 1,4 substitution on the benzene ring) and CsBr are formulated into a solution to obtain a blue light perovskite precursor solution; PbBr in the blue light perovskite precursor solution 2 The concentration of F-PEABr is 0.2mmol / mL, the concentration of F-PEABr is 0.28mmol / mL, and the concentration of CsBr is 0.1mmol / mL;

[0084] b. Before spin-coating the electron transport layer (ZnO), O 2 -Plasma treatment to improve wettability on ITO, transfer substrate into N 2 In the glove box; Spin coating at 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com