Treatment method of chemical synthesis pharmaceutical wastewater

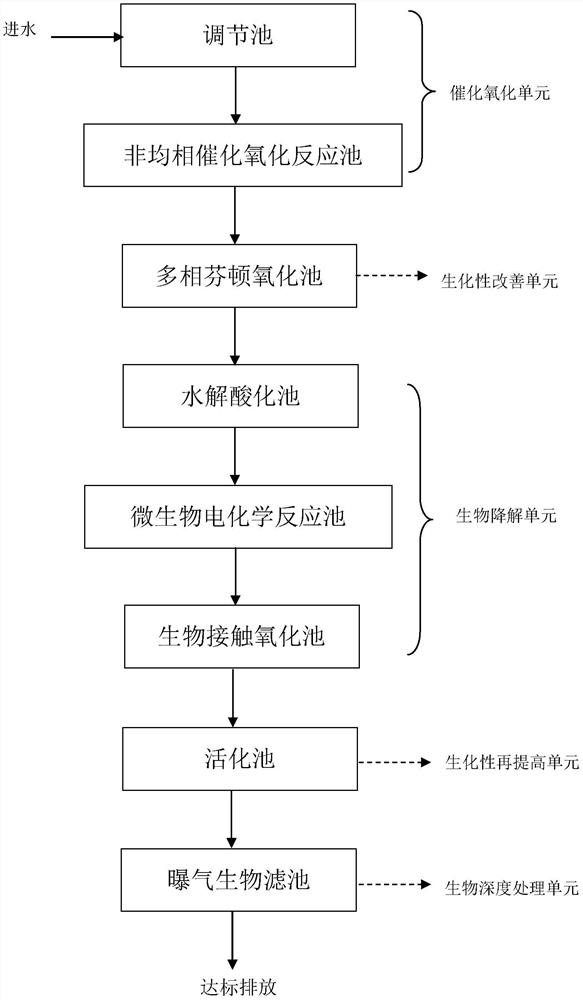

A technology for pharmaceutical wastewater and chemical synthesis, which is applied in the fields of special compound water treatment, electrochemical biocombination treatment, chemical instruments and methods, etc. Acid corrosion and other problems, to achieve the effect of significant COD removal rate, appropriate and reasonable combination, and compact cascade reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

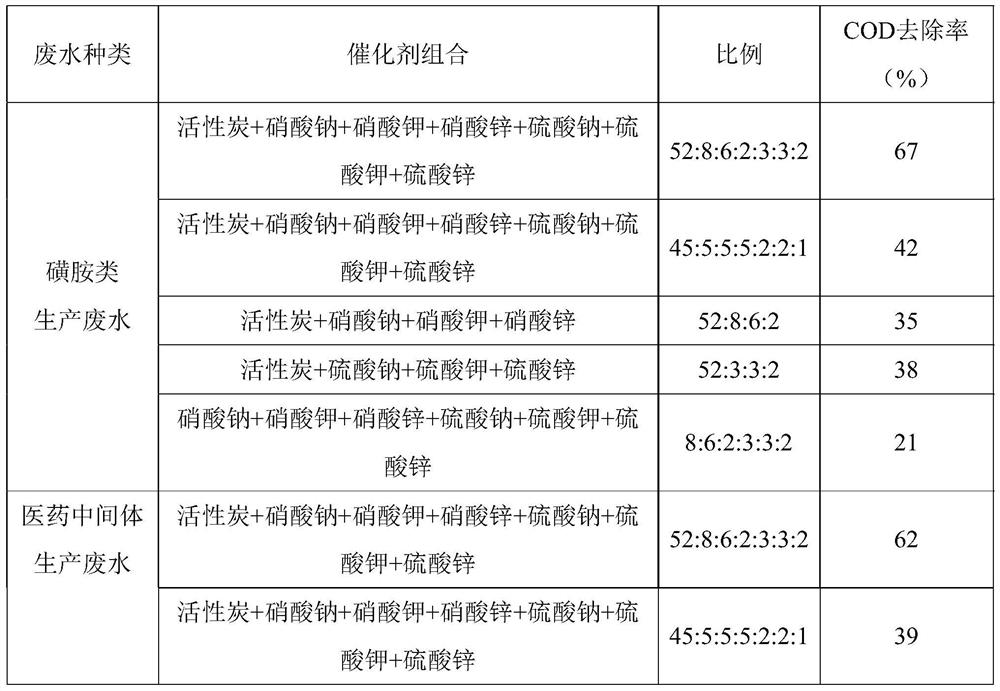

Embodiment 1

[0067] Example 1: A certain pharmaceutical factory in Jiangsu Province is a medium-sized pharmaceutical enterprise mainly engaged in the synthesis of chemical raw materials. Production wastewater contains refractory organic substances such as stupid, toluene, and chlorobenzene. The wastewater indicators are: COD concentration 8000-13000mg / L, BOD concentration 2240-3640mg / L, NH 3 -N concentration is 550-872mg / L, pH value is 6.2-6.8, the fluctuation range is not large, the ratio of BOD to COD (B\C) is less than 0.3, and the biodegradability is poor. Adopt the treatment method of a kind of chemical synthesis class pharmaceutical waste water that the present invention relates to to process, concrete treatment process is as follows:

[0068] Catalytic oxidation unit: discharge the pharmaceutical wastewater into the adjustment tank, add sodium hydroxide to adjust the pH value of the wastewater to 6.5-7.5, discharge the adjusted wastewater into the heterogeneous catalytic oxidation r...

Embodiment 2

[0074] Embodiment 2: A pharmaceutical factory in Shandong Province is a medium-sized pharmaceutical enterprise mainly producing sulfonamides and antipyretic and analgesic drugs. Production wastewater contains methanol, acetone, methylene chloride, and aromatic hydrocarbons and other refractory organic substances. The wastewater indicators are: COD concentration 9000-11000mg / L, BOD concentration 1890-2250mg / L, NH 3 -N concentration is 420-505mg / L, pH value is 6.5-7.2, BOD to COD ratio (B\C) is less than 0.3, and the biodegradability is poor. Adopt the treatment method of a kind of chemical synthesis class pharmaceutical waste water that the present invention relates to to process, concrete treatment process is as follows:

[0075] Catalytic oxidation unit: discharge the pharmaceutical wastewater into the regulating tank, discharge the mixed wastewater into the heterogeneous catalytic oxidation reaction tank, turn on the ultraviolet light, the wavelength range is 300-325nm, and ...

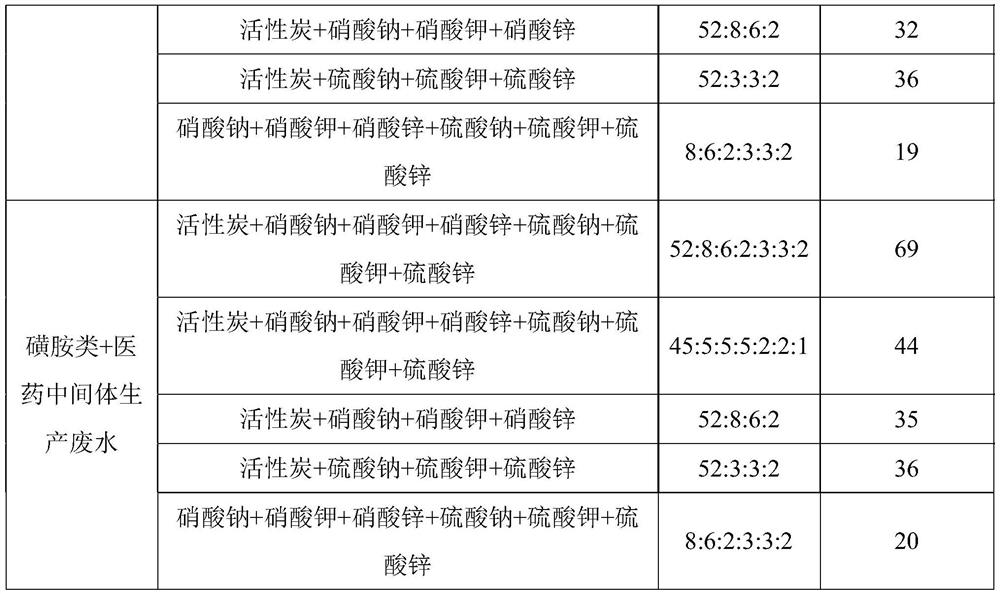

Embodiment 3

[0081] Example 3: A pharmaceutical factory in Shandong Province is a large-scale pharmaceutical enterprise mainly engaged in the production of antibiotics and synthesis of antineoplastic drugs. Production wastewater contains complex components such as methanol, acetone, methylene chloride, pyridine, aromatic hydrocarbon rings, and heterocycles, and contains nitro, nitrogen-based aromatic compounds and other substances, which are highly toxic and have an inhibitory effect on activated sludge. Biochemical is very poor. Wastewater indicators are: COD concentration 9820-14000mg / L, BOD concentration 1980-2860mg / L, NH 3 -N concentration is 600-950mg / L, pH value is 6.0-6.5, the water quality is acidic, the ratio of BOD to COD (B\C) is about 0.2, and the biodegradability is poor. Adopt the treatment method of a kind of chemical synthesis class pharmaceutical waste water that the present invention relates to to process, concrete treatment process is as follows:

[0082] Catalytic oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com