Method and system for extracting palm oil from fresh palm fruit

A complete set of equipment, palm oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of unable to achieve large-scale production, unable to meet modern production, unable to use palm fruit, etc., to achieve reasonable equipment screening and combination, production. The effect of large capacity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

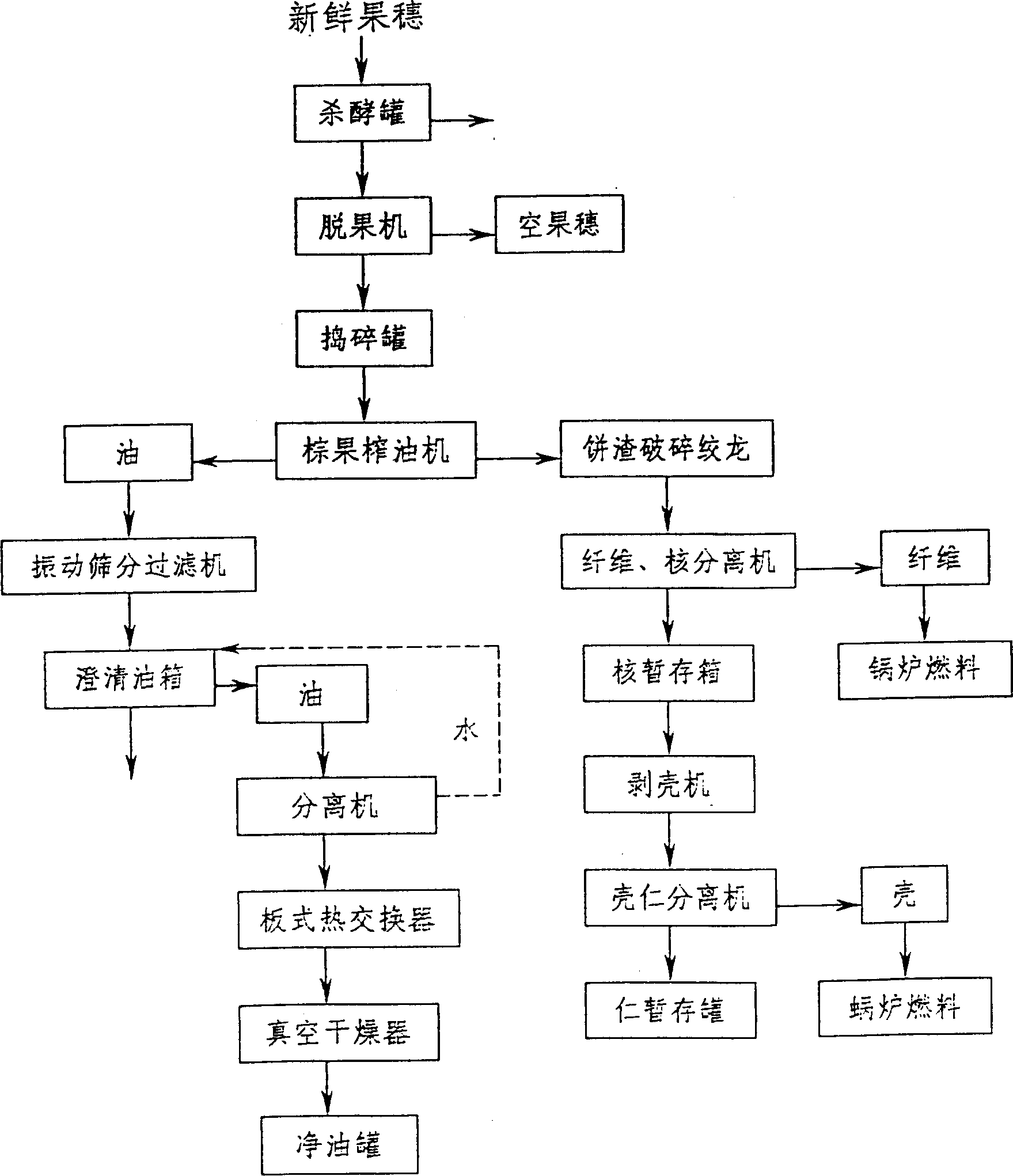

[0018] Below in conjunction with process flow chart and complete set of equipment flow chart, the method of the present invention is further described:

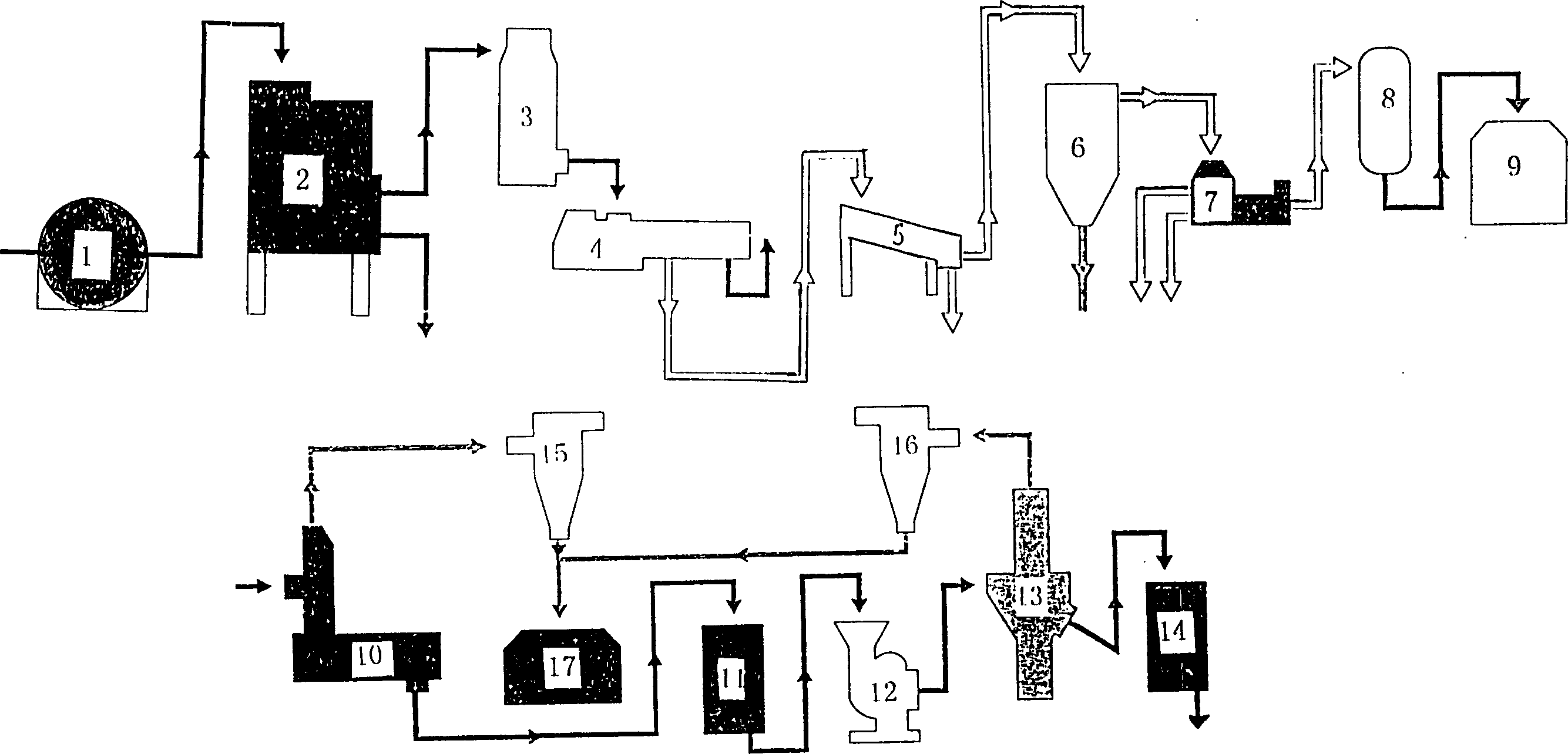

[0019] like figure 2 As shown, the complete set of equipment of the present invention is composed of the following equipment in sequence: sterilizing tank 1, fruit thresher 2, mashing tank 3, double screw oil press 4, vibrating separator 5, clarified oil tank 6, oil purification separator 7. Plate heat exchanger 8. Vacuum dryer 9. The overflow outlet at the tail end of the twin-screw oil press 4 is also sequentially connected with a fiber core separator 10, a blast dryer 11, a centrifugal corrugated sheller 12, a core-shell separator 13, and a kernel dryer 14; The fiber outlet of the fiber core separator 10 is connected with a fiber deduster 15, the core shell outlet of the core shell separator 13 is connected with a core shell deduster 16, and the outlets of the fiber deduster 15 and the core shell deduster 16 pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com