A kind of outdoor super-weather resistant powder coating and preparation method thereof

A powder coating and super weather-resistant technology, applied in powder coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of lack of reinforced mechanical structure, unavoidable mechanical damage, low surface energy, etc., to achieve enhanced curing effect, enhanced structural performance, The effect of increasing the surface contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

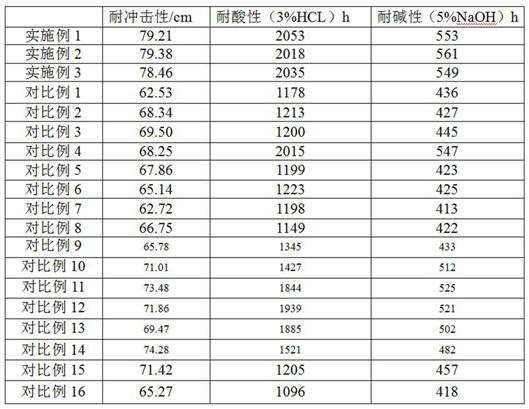

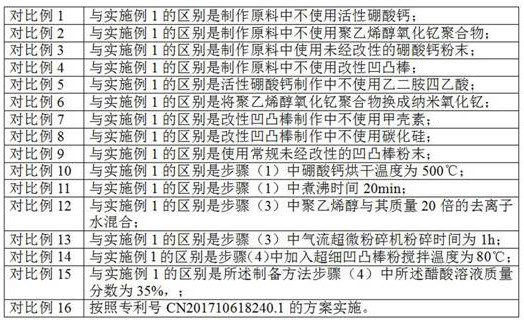

Examples

Embodiment 1

[0031] An outdoor super-weather-resistant powder coating, the raw materials are calculated in parts by weight, 300 parts of epoxy resin, 80 parts of fluorosilicone resin, 150 parts of polyhexamethylene adipamide, 20 parts of dibenzoyl peroxide, and nano-alumina 15 parts, 30 parts of active calcium borate, 8 parts of polyvinyl alcohol yttrium oxide polymer, 3 parts of nano-boron nitride, 5 parts of modified attapulgite; described active calcium borate is composed of nano-boric acid with a mass ratio of 13:2:1 calcium, sodium pimarate, and ethylenediaminetetraacetic acid; the polyvinyl alcohol yttrium oxide polymer is prepared from polyvinyl alcohol and yttrium oxide with a mass ratio of 15:1; the modified attapulgite is prepared from a mass ratio of It is prepared from ultra-fine attapulgite powder, chitin, nano-silicon carbide, and fluororubber at a ratio of 35:5:0.1:85; the fineness of the yttrium oxide is 300 mesh; the fineness of the ultrafine attapulgite powder is 1000 mesh...

Embodiment 2

[0046] An outdoor super-weather-resistant powder coating, the raw materials are calculated in parts by weight, 500 parts of epoxy resin, 100 parts of fluorosilicone resin, 200 parts of polyhexamethylene adipamide, 30 parts of dibenzoyl peroxide, and nano-alumina 20 parts, 50 parts of active calcium borate, 12 parts of polyvinyl alcohol yttrium oxide polymer, 5 parts of nano-boron nitride, and 8 parts of modified attapulgite; Calcium, sodium pimarate, ethylenediaminetetraacetic acid are prepared from; the polyvinyl alcohol yttrium oxide polymer is prepared from polyvinyl alcohol and yttrium oxide with a mass ratio of 21: 5; the modified attapulgite is prepared from a mass ratio of It is prepared from ultrafine attapulgite powder, chitin, nano-silicon carbide, and fluororubber at 46:8:0.3:96; the fineness of the yttrium oxide is 400 mesh; the fineness of the ultrafine attapulgite powder is 1500 mesh .

[0047] The outdoor super-weather-resistant powder coating described in the ...

Embodiment 3

[0061] An outdoor super-weather-resistant powder coating, the raw materials are calculated in parts by weight, 440 parts of epoxy resin, 90 parts of fluorosilicone resin, 190 parts of polyhexamethylene adipamide, 25 parts of dibenzoyl peroxide, and nano-alumina 20 parts, 30 parts of active calcium borate, 12 parts of polyvinyl alcohol yttrium oxide polymer, 3 parts of nano boron nitride, 8 parts of modified attapulgite; Described active calcium borate is by the nano boric acid that mass ratio is 13: 4: 1 calcium, sodium pimarate, and ethylenediaminetetraacetic acid; the polyvinyl alcohol yttrium oxide polymer is prepared from polyvinyl alcohol and yttrium oxide with a mass ratio of 21:1; the modified attapulgite is prepared from a mass ratio of It is prepared from ultra-fine attapulgite powder, chitin, nano-silicon carbide, and fluororubber at a ratio of 46:5:0.3:85; the fineness of the yttrium oxide is 400 mesh; the fineness of the ultrafine attapulgite powder is 1000 mesh . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com