Composite conductive paste as well as preparation method and application thereof

A technology for compounding conductive and conductive materials, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., and can solve poor dispersion effect of slurry, uneven particle size distribution, particle agglomeration, etc. Problems, achieve the effect of improving the resistivity of the electrode sheet, green and environmentally friendly dispersion, and not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the commonly used composite conductive paste is generally as follows: firstly, the first conductive particles are mixed with a solvent and then dispersed in a sand mill to obtain the first conductive paste; secondly, the second conductive particles are mixed with a solvent and then added with sand Disperse in a mill to obtain a second conductive paste; finally, mix the first conductive paste with the second conductive paste, add to a sand mill to disperse, and finally obtain a composite conductive paste. Although the above-mentioned method of using a sand mill for multiple feed wet grinding can obtain a conductive paste with uniform properties, the above-mentioned method is complicated to operate and has low grinding efficiency. At the same time, because the conductive particles are mixed in batches, after the slurry is placed for a certain period of time, the conductive particles still have the phenomenon of agglomeration and sedimentation, and...

Embodiment 1

[0083] Composite conductive paste is prepared as follows:

[0084] a. Weigh 0.2wt% of wetting agent polyvinylpyrrolidone K30, 0.5wt% of thickener polyvinylidene fluoride HSV900 and 91.5wt% of solvent N-methylpyrrolidone, and stir at 600r / min under vacuum conditions Time 2h, obtain the uniform transparent glue solution standby;

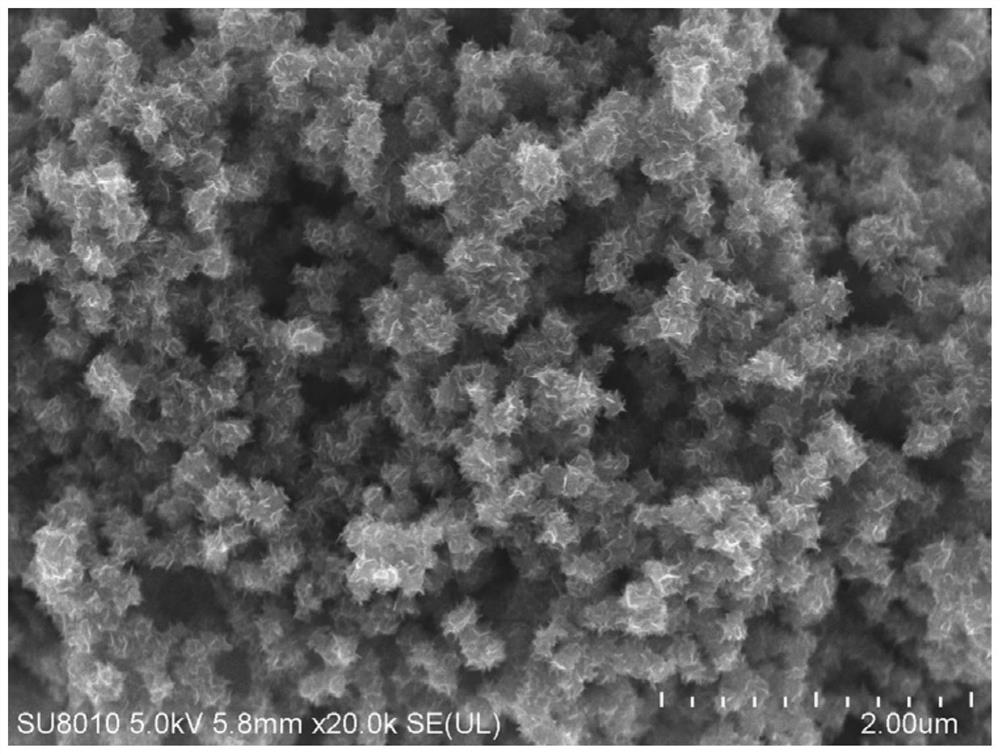

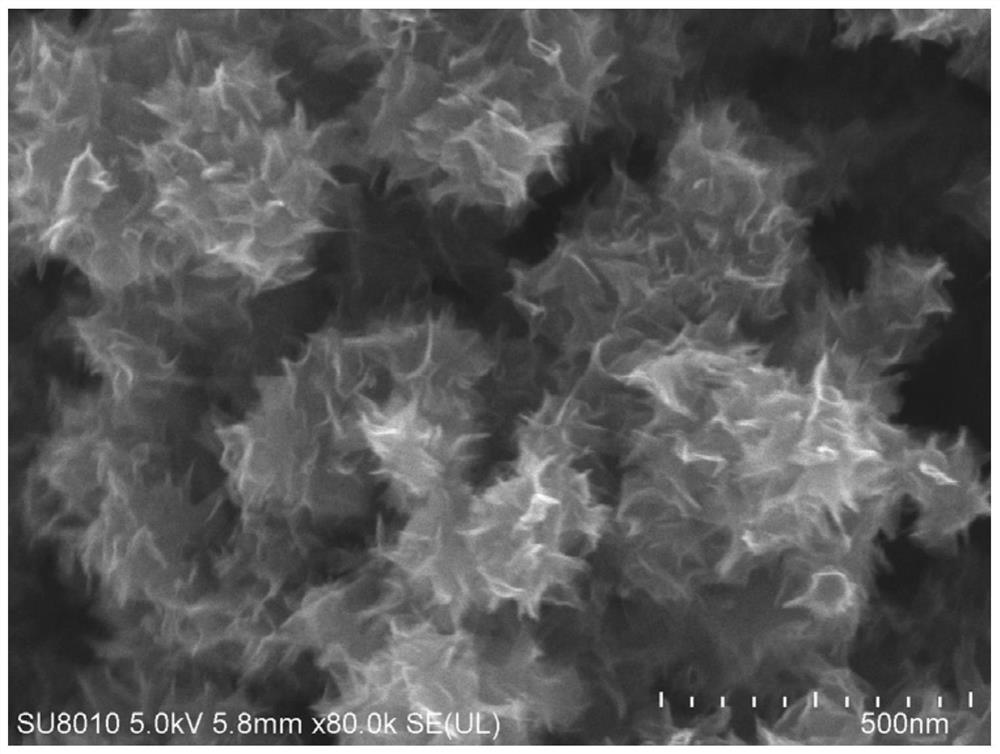

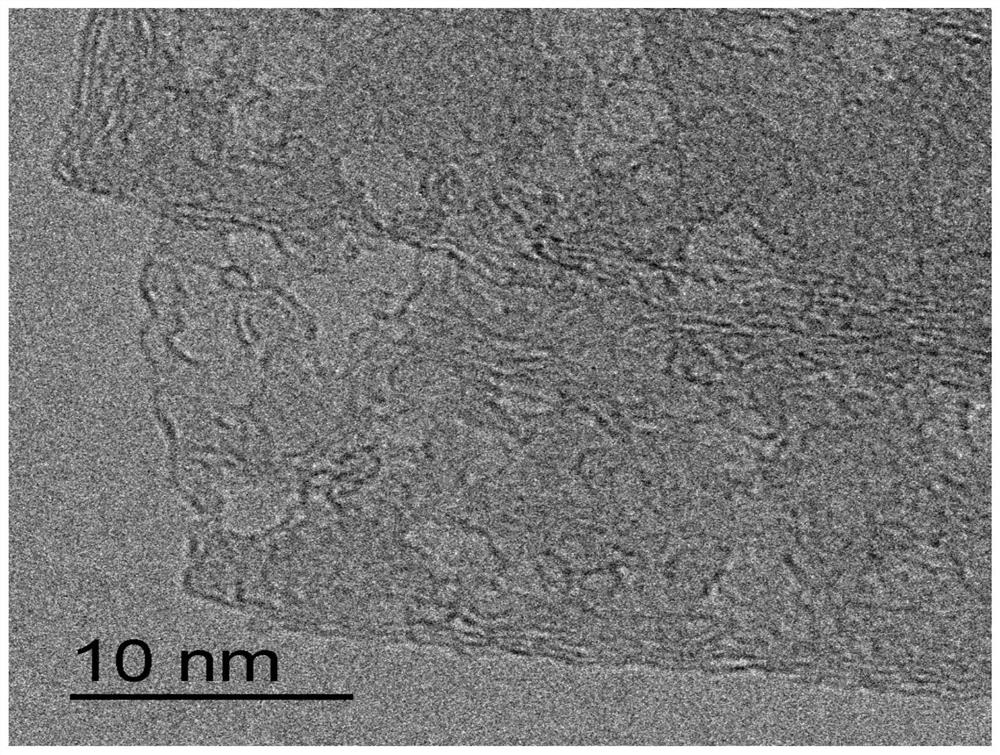

[0085] b. Weigh 6% of the three-dimensional graphene particles, 1wt% of the composite conductive agent carbon nanotubes and 0.8wt% of the surfactant sodium dodecylbenzenesulfonate, and use a ball mill to dry grind. For dry grinding, 0.8mm zirconia zirconia beads were used at a speed of 300r / min, and the ball milling time was 2h.

[0086] c. Put the glue solution prepared in step (a) and the mixed powder prepared in step (b) into an overhead mixer in turn at 800r / min, stirring for 10min, to obtain a mixed slurry.

[0087] d. The mixed slurry prepared in step (c) was wet-milled with a pin-type sand mill. The diameter of the zirconium beads used in the ...

Embodiment 2

[0092] Composite conductive paste is prepared as follows:

[0093] a. Weigh 0.2wt% of wetting agent polyethylene glycol, 0.5wt% of thickener sodium alginate and 91.5wt% of solvent absolute ethanol, rotate at 600r / min under vacuum conditions, and stir for 2h to obtain Uniform and transparent glue for use;

[0094] b. Weigh 6% of the three-dimensional graphene particles, 1wt% of the composite conductive agent nano-carbon fiber and 0.8wt% of the surfactant sodium dodecylbenzenesulfonate, and use a ball mill to dry grind. Dry grinding uses 0.6mm zirconia zirconia beads at a speed of 300r / min, and the ball milling time is 2.5h.

[0095] c. Put the glue solution prepared in step (a) and the mixed powder prepared in step (b) into an overhead mixer in turn at 800r / min, stirring for 15min, to obtain a mixed slurry.

[0096] d. The mixed slurry prepared in step (c) was wet-milled with a pin-type sand mill. The diameter of the zirconium beads used in the wet-milling was 0.3mm, the rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com