A novel magnetic aluminum-based composite material, its preparation method and its use

An aluminum-based composite material and magnetic technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of easy corrosion, difficult multi-pole magnetization of magnets, and high temperature coefficient of remanence, and achieves enhanced thermal conductivity. Conductivity, prevention of inhomogeneous structure, effect of grain size refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

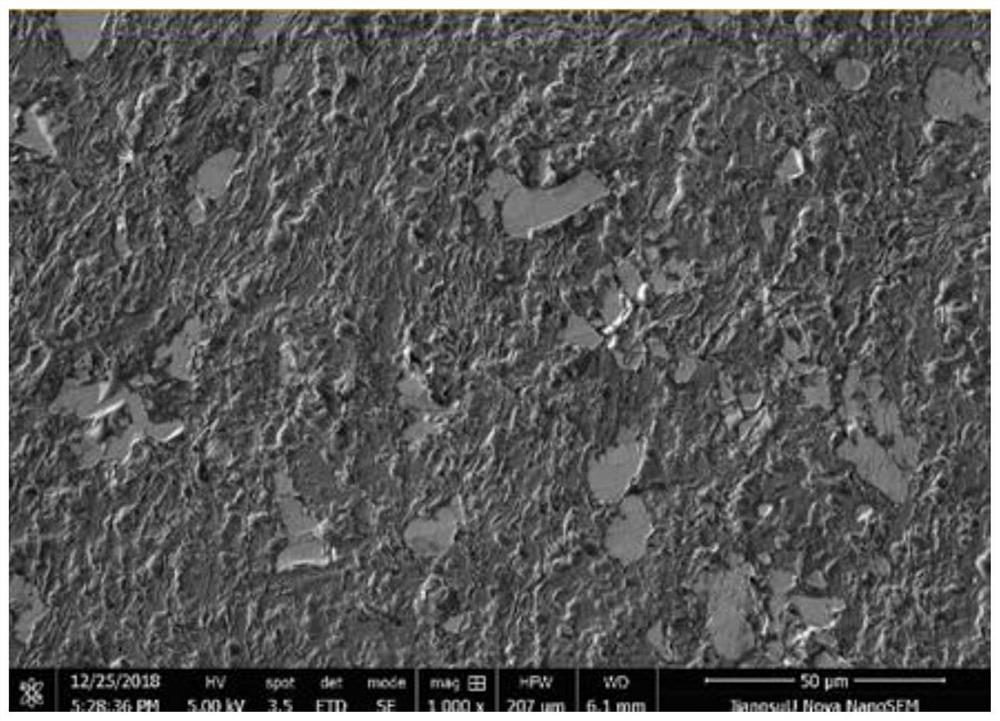

[0040] The matrix material of the novel aluminum matrix composite material of this embodiment is 2024 aluminum alloy, and the composition of composite phase is: NdFeB powder 17.5wt.%, Co 2.4wt.%, Ni 2%, rare earth Sm 0.2wt.%. The powder of the composite phase and the base phase 2024 aluminum alloy powder are mixed in proportion. Composite materials were then prepared as follows:

[0041] (1) High energy ball mill

[0042] Adopt the method of graded ball milling, that is, firstly grind large-sized NdFeB, aluminum powder, cobalt powder and samarium powder at high speed respectively. 3:2:1, the ratio of alcohol to powder is 3:5, and the ball milling time is 15 hours. Then the ball-milled powder is carried out in a low-speed ball mill according to the design ratio to achieve uniform material mixing. The material ratio is 3:5.

[0043] (2) Magnetic field static pressure forming

[0044] The ball-milled powder was pressed under isostatic pressure of 300MPa for 30 minutes, and t...

Embodiment 2

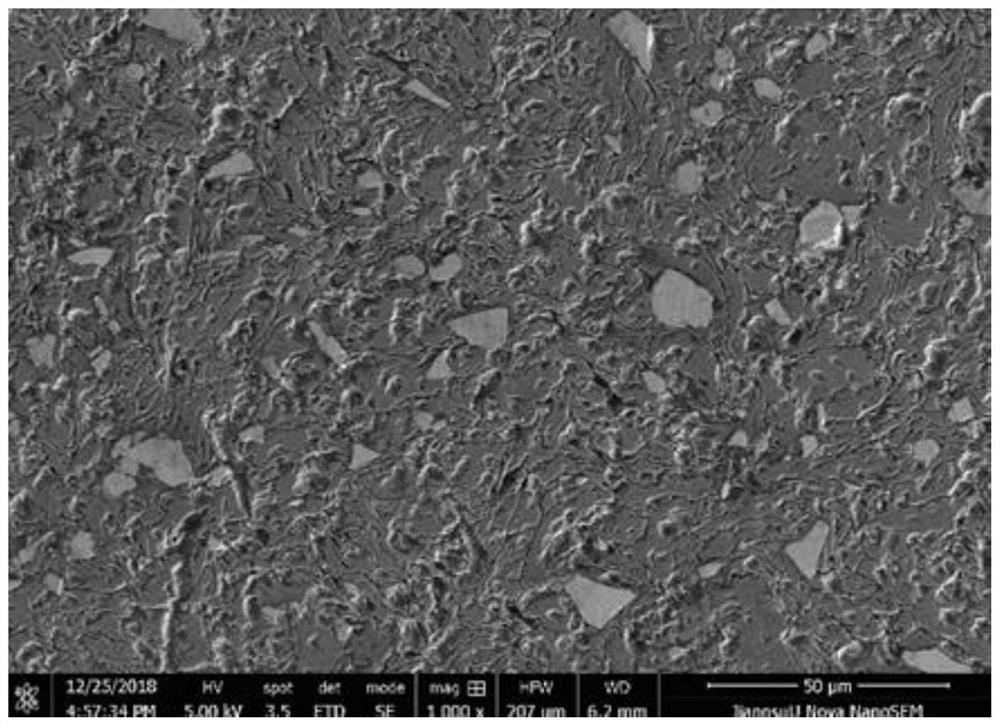

[0054] The base material of the novel aluminum-based composite material in this embodiment is 2024 aluminum alloy, and the composition of the composite phase is: NdFeB powder 18wt.%, Co 4.8wt.%, Ni 4%, rare earth Sm 0.4wt.%. The powder of the composite phase and the 2024 aluminum alloy powder of the base phase are mixed in proportion. Composite materials were then prepared as follows:

[0055] (1) High energy ball mill

[0056] Adopt the method of graded ball milling, that is, firstly grind large-sized NdFeB, aluminum powder, cobalt powder and samarium powder at high speed respectively. 3:2:1, the ratio of alcohol to powder is 3:5, and the ball milling time is 15 hours. Then the ball-milled powder is carried out in a low-speed ball mill according to the design ratio to achieve uniform material mixing. The material ratio is 3:5.

[0057] (2) Magnetic field static pressure forming

[0058] The ball-milled powder was pressed and formed under isostatic pressure conditions of ...

Embodiment 3

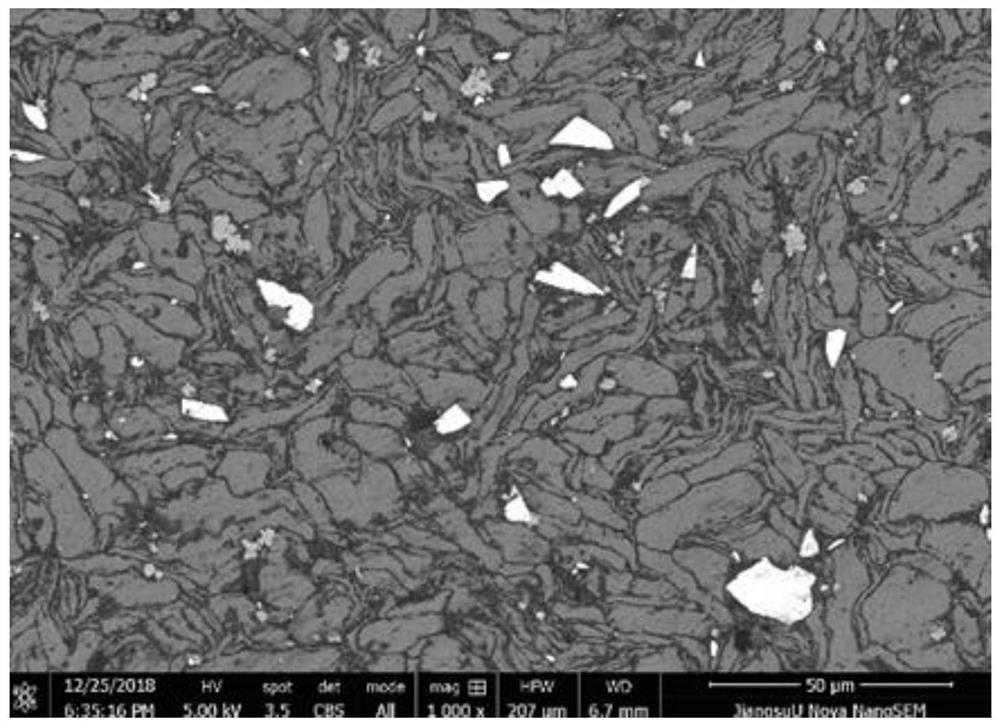

[0068] The matrix material of the novel aluminum-based composite material in this embodiment is 2024 aluminum alloy, and the composition of the composite phase is: NdFeB powder 20.6wt.%, Co 7.2wt.%, Ni 6%, rare earth Sm 0.6wt.%. The powder of the composite phase and the base phase 2024 aluminum alloy powder are mixed in proportion. Composite materials were then prepared as follows:

[0069] (1) High energy ball mill

[0070] Adopt the method of graded ball milling, that is, firstly grind large-sized NdFeB, aluminum powder, cobalt powder and samarium powder at high speed respectively. 3:2:1, the ratio of alcohol to powder is 3:5, and the ball milling time is 15 hours. Then the ball-milled powder is carried out in a low-speed ball mill according to the design ratio to achieve uniform material mixing. The material ratio is 3:5.

[0071] (2) Magnetic field static pressure forming

[0072] The ball-milled powder was pressed into shape under the condition of 300MPa isostatic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com