Gradient composite material and preparation method thereof

A composite material and layered composite material technology, applied in the field of gradient composite material preparation, can solve the problems of poor interface bonding strength of composite materials, affecting the service life of electric arcs, and easy cracking at the edge of composite materials, etc., to achieve excellent comprehensiveness Processing performance, low-voltage electrical appliances are not easy to burn out, and the effect of improving quality stability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

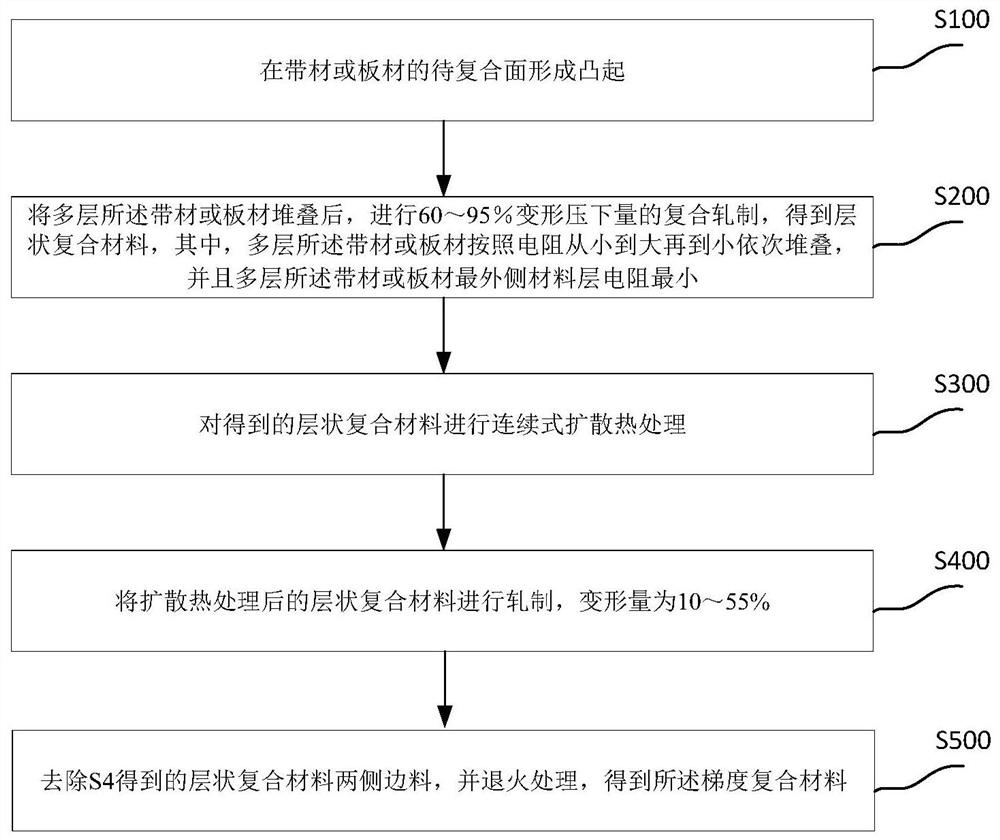

[0043] figure 1 This is a flow chart of a method for preparing a gradient composite material according to an embodiment of the present invention. refer to figure 1 As shown, a preparation method of a gradient composite material may include the following steps:

[0044] S100: Protrusions are formed on the surface to be composited of the strip or plate.

[0045] Specifically, in a preferred embodiment, a special-shaped roller is used to roll a raised pattern on the surface to be compounded of the strip or plate. The profiled roller means that the surface of the roller has grooves along the circumferential direction, or grooves along the direction parallel to the roller axis, or grooves along the circumference and parallel to the roller axis. The grooves match the protrusions. Further, the protrusions may be rib along the direction parallel to the roller axis, may be the rib along the direction perpendicular to the roller axis, may be a grid-like rib, or may be a raised bubbl...

Embodiment 1

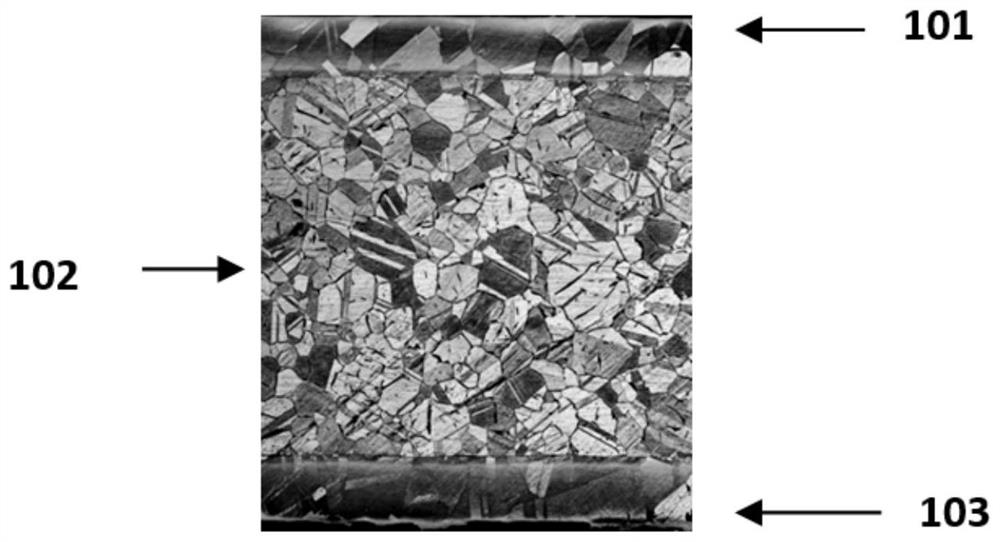

[0062] to prepare as figure 2 Taking the gradient composite material H85 / H65 / H85 as an example, the first material layer 101 is H85 brass; the second material layer 102 is H65 brass; and the third material layer 103 is H85 brass.

[0063] The thickness of the second material layer 102 is 80% of the total thickness of the gradient composite material, and the total thickness of the first material layer 101 and the third material layer 103 is 20% of the total thickness of the gradient composite material. The thickness of the first material layer 101 is 10% of the total thickness of the gradient composite.

[0064] S1: use such as image 3 The special-shaped roller shown, rolls the surface of the H65 strip to be compounded to form a circular arc-shaped convex rib along the direction parallel to the roll axis. Of course, the cross-sectional shape of the convex rib can also be one of trapezoid, triangle, rhombus or rectangle. Or a combination of two or more of them.

[0065] S2:...

Embodiment 2

[0074] to prepare as Figure 4 The gradient composite material TU1 / H68 is shown as an example, the first material layer 201 is TU1 oxygen-free copper; the second material layer 202 is H68 brass.

[0075] The thickness of the second material layer 202 is 70% of the total thickness of the gradient composite material; the first material layer 201 is 30% of the total thickness of the gradient composite material.

[0076] S1: use such as Figure 5 The profiled roll shown, rolls the surface to be clad of the H68 strip to form triangular protrusions along the direction perpendicular to the roll axis.

[0077] S2: Use a wire brush to clean the upper and lower surfaces of the TU1 strip and H68 strip to remove the surface oxide layer and increase the surface roughness to make Ra not less than 1.0μm.

[0078] S3: Stack the strip treated by S2 in two layers, and perform special-shaped composite rolling with 85% deformation reduction. At the same time, the upper and lower rolls are conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com