Anti-corrosion temperature-resistant adhesive for desulfurization chimney and preparation method of same

An adhesive and temperature-resistant technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as poor construction performance, low elongation at break, general high temperature resistance, etc., to achieve Increased chemical resistance and hydrophobicity, improved tensile strength and elongation at break, good corrosion resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

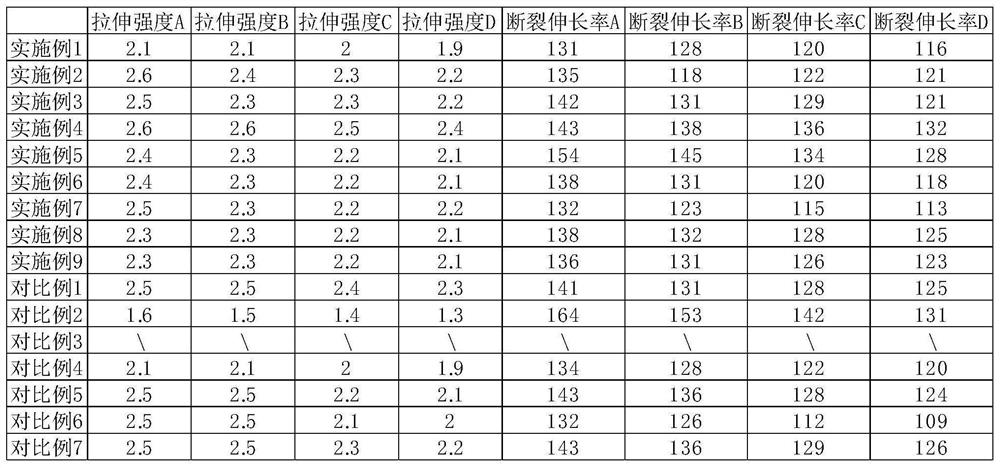

Examples

Embodiment 1

[0051] Step a: 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 80000mPa.s / 25°C, 10 parts of fluorosilicone oil with a viscosity of 10000mPa.s / 25°C, and a viscosity of 1000mPa.s / 25°C Add 5 parts of polydimethylsilicone oil at ℃, 100 parts of mica powder, 30 parts of titanium dioxide, and 5 parts of fumed white carbon black into a vacuum high-speed disperser and mix evenly to obtain component A;

[0052] Step b: 100 parts of polydimethylsiloxane with a viscosity of 1000mPa.s / 25°C, 50 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 5000mPa.s / 25°C, propylene orthosilicate Add 100 parts of ester, 10 parts of aminoethylaminopropyltriethoxysilane, 40 parts of carbon black, and 0.1 part of dibutyltin dilaurate into a vacuum high-speed disperser and stir for 60 minutes to obtain component B.

[0053] Mix A and B components uniformly in a vacuum defoamer according to the mass ratio A:B=13:1 to obtain an anti-corrosion and temperature-resistant adhesive...

Embodiment 2

[0055] Step a: 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa.s / 25°C, 30 parts of hydroxyfluorosilicone oil with a viscosity of 10000mPa.s / 25°C, and a viscosity of 100mPa.s / Add 20 parts of polydimethylsiloxane oil, 50 parts of mica powder, 100 parts of talc powder, 60 parts of kaolin, 4 parts of fumed silica, and 12 parts of organic montmorillonite at 25°C into a vacuum high-speed disperser and mix evenly to prepare A components;

[0056] Step b: 100 parts of polydimethylsiloxane with a viscosity of 100mPa.s / 25°C, 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 1000mPa.s / 25°C, ethyl orthosilicate Add 200 parts of ester, 30 parts of glycidoxypropyltrimethoxysilane, 80 parts of carbon black, and 0.5 part of dibutyltin dioctoate into a vacuum high-speed disperser and stir for 30 minutes to obtain component B.

[0057] Mix A and B components uniformly in a vacuum defoamer according to the mass ratio A:B=18:1 to obtain an anti-corro...

Embodiment 3

[0059] Step a: 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 40000mPa.s / 25°C, 20 parts of hydroxyfluorosilicone oil with a viscosity of 5000mPa.s / 25°C, and a viscosity of 500mPa.s / Add 12 parts of polydimethylsiloxane oil, 80 parts of mica powder, 20 parts of fluorite powder, 20 parts of titanium dioxide, 40 parts of silicon micropowder, 4 parts of fumed white carbon black, and 12 parts of active nano-calcium carbonate at 25°C into the vacuum high-speed disperser Mix uniformly in medium to obtain component A;

[0060] Step b: 100 parts of polydimethylsiloxane with a viscosity of 500mPa.s / 25°C, 70 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 500mPa.s / 25°C, methyl triethyl Add 150 parts of oxysilane, 20 parts of aminoethylaminopropyltrimethoxysilane, 60 parts of carbon black, and 0.3 part of dibutyl tin dioctoate into a vacuum high-speed disperser and stir for 30 minutes to obtain component B.

[0061] Mix A and B components uniformly in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com