Method for regulating and limiting rotational speed of turbocharger

A turbocharger, speed technology, applied in electrical control, engine control, machine/engine, etc., can solve problems such as unreliable protection of turbochargers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

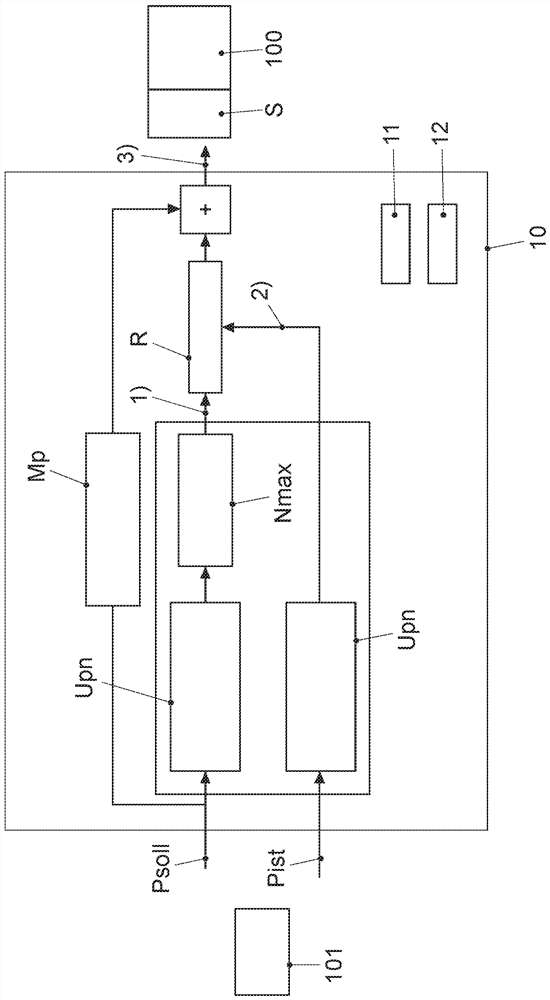

[0049] In the different figures, identical features of the invention are always provided with the same reference symbols, so they are generally only described once.

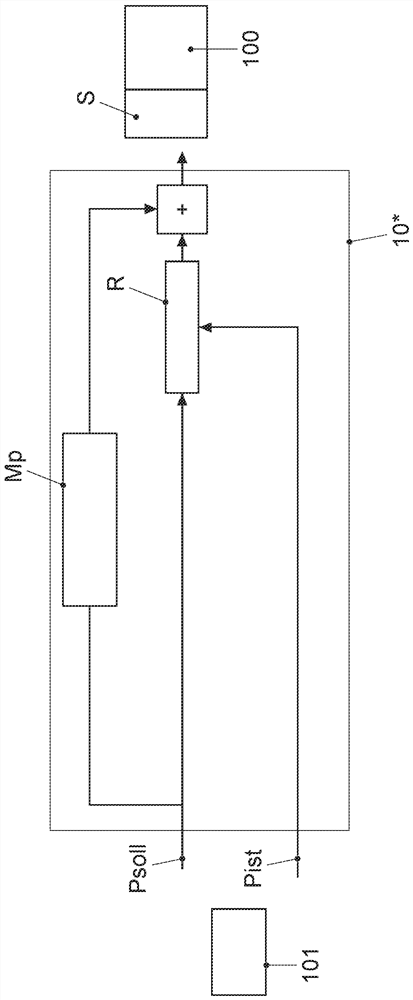

[0050] figure 1 The known control principle of the control variable in the operation of the turbocharger 100 is shown schematically, in which the boost P of the turbocharger 100 is regulated as the control variable.

[0051] The purpose of the regulation is to ensure that turbocharger 100 provides sufficient power at low exhaust gas flows and that its load limit, in particular its maximum permissible rotational speed N, is not exceeded as much as possible at high rotational speeds.

[0052] as in figure 1 As shown in , in the known case of boost regulation, engine control unit 10 * calculates a setpoint boost Psoll upstream of turbocharger 100 by means of model-based pilot control Mp. The model-based pre-control Mp is based on the known Euler turbine master equations.

[0053] A pressure sensor before the turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com