A Soft Crawler Pipeline Robot

A pipeline robot and crawler-type technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of unreliable transmission movement, reduced driving wheel speed, poor running stability, etc., and achieve stable and reliable robot operation , Reduce energy loss, large axial traction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

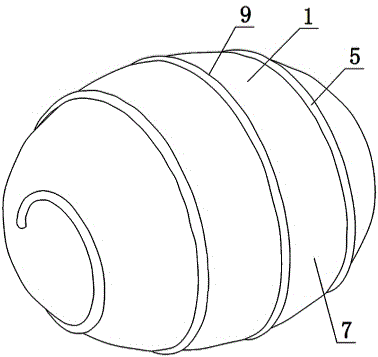

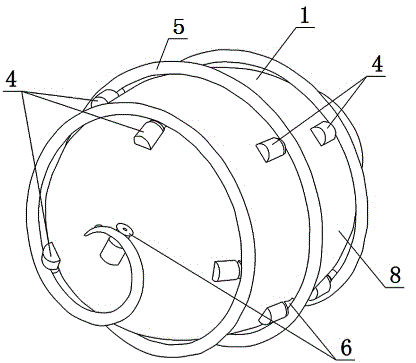

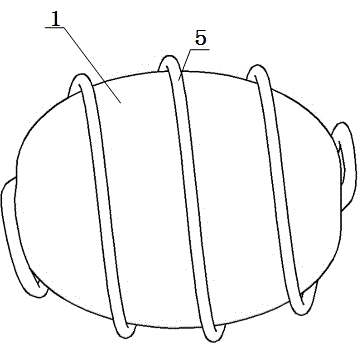

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a soft tracked pipeline robot includes an inflatable expansion body 1 and a motion actuator. The inflatable expansion body 1 is made of flexible materials. The interior of the inflatable expansion body 1 is a closed inflatable cavity. The inflation and deflation device connected to the inflation cavity, the center of the inflation and expansion body 1 is provided with an axial channel 3, and the motion execution device includes a drive motor 4 and a crawler 5, and the crawler 5 is spirally closed and arranged on the surface of the inflation and expansion body 1 , the spiral closure is that the caterpillar 5 is spirally wound around the outer surface of the inflatable body 1 from one end of the inflatable body 1, and the crawler 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com