Throttling type gas-liquid exchange device

A gas-liquid exchange and throttling technology, used in separation devices, using liquid separation agents, cleaning hollow objects, etc., can solve problems such as unsolved equipment water consumption, waste of water resources, and water cannot flow naturally from the overflow port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

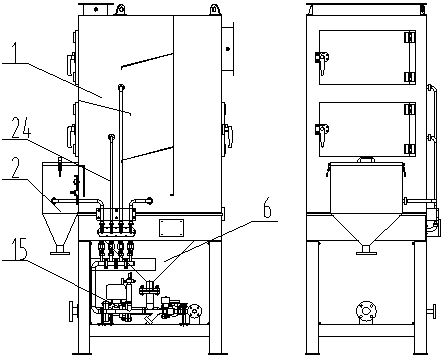

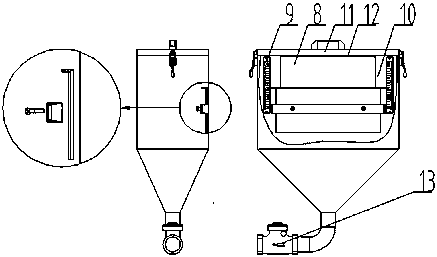

[0032] like figure 1 As shown, the throttling type gas-liquid exchange device of the present invention comprises: main box body 1, negative pressure water tank 2, inlet and outlet 3, as Figure 5 The shown main box 1 has an air inlet 4, an air outlet 5, a throttle plate 7, an overflow port 8, and a water baffle 14. An induced draft fan is arranged at the air outlet 5, and the throttle plate 7 is vertical Fixed in the main box body 1, the main box body 1 is divided into two parts: the air inlet chamber and the air outlet chamber, the air inlet port 4 is located in the air inlet chamber, the air outlet port 5 is located in the air outlet chamber, and the inlet and outlet ports 3 are located in the main box body The bottom of 1 is used to supply water or drain water to the main box 1. The water baffles 14 are distributed on the throttling plate 7 and the wall of the main box 1 in sequence, parallel to the horizontal plane, and the distance between them is equal. The overflow por...

Embodiment 2

[0036] like Image 6 As shown, the throttling gas-liquid exchange device chamber provided in this embodiment is based on the first embodiment, and a settling bucket 6 is arranged under the main box body 1 , and an inlet and outlet 3 are arranged at the bottom of the settling bucket 6 .

[0037] The repose angle α of the settling bucket 6 can make the ash in the settling bucket 6 settle to the bottom of the box bucket. The angle of the angle of repose α of the descending bucket 6 is 45°. Setting the settling bucket 6 can make the dust entering the water enter the bottom of the settling bucket 6, and can realize fast replenishment and discharge of water.

Embodiment 3

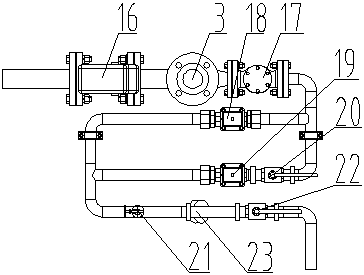

[0039] like image 3 As shown, the throttling type gas-liquid exchange device chamber provided in this embodiment is based on the second embodiment, and an inlet and drain component 15 is added to the throttle type gas-liquid exchange device. Connection, the inlet and outlet parts 15 include the drain electric ball valve 16, the check valve 17, the water inlet solenoid valve 18, the water replenishment solenoid valve 19, the water replenishment control manual ball valve 20, the water hammer buffer 21, the total water inlet control manual ball valve 22, the filter 23. The water replenishment solenoid valve 19 and the water replenishment control manual ball valve 20 are connected in series, and the water inlet solenoid valve 18 and the water replenishment solenoid valve 19 and the water replenishment control manual ball valve 20 connected in series are respectively connected in two branches to form a parallel connection, and one end of the branch is connected in parallel. It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com