Oil-free non-curing rubber asphalt waterproof coating capable of low temperature construction and preparation method thereof

A kind of asphalt waterproof coating, non-curing rubber technology, applied in asphalt coating, rosin coating, coating, etc., can solve the problems of oil leakage, poor aging resistance, etc., to avoid oil separation analysis, good low temperature resistance, reduce high temperature aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

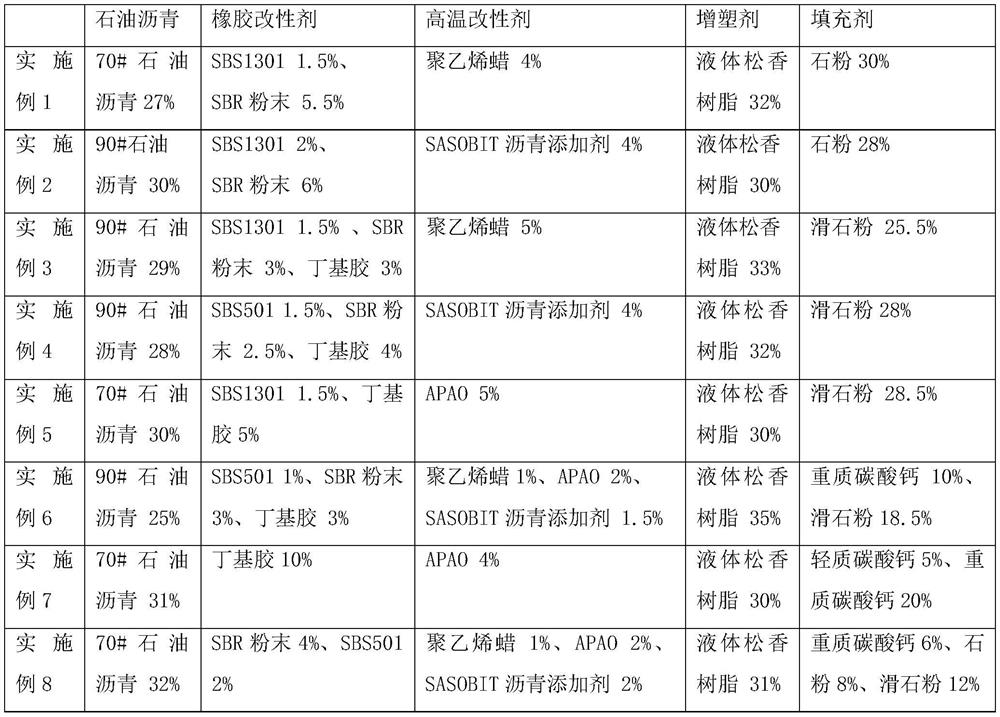

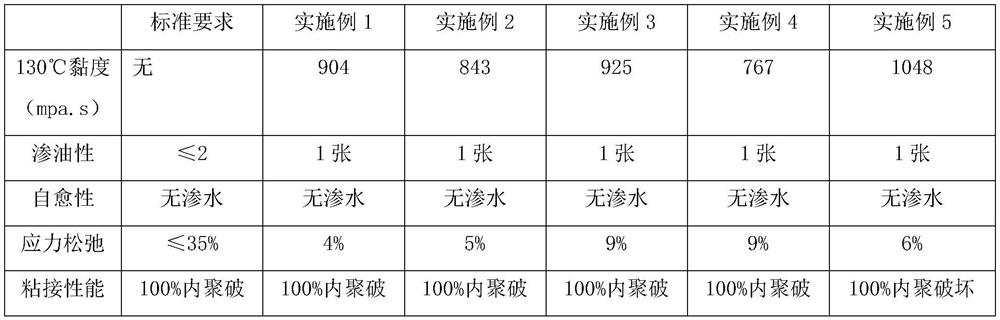

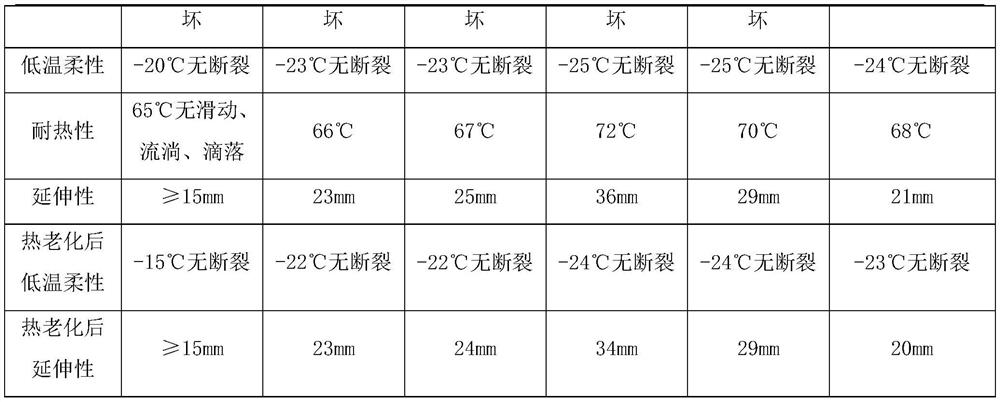

Embodiment 1

[0027] A kind of preparation method of non-cured rubber asphalt waterproof coating of oil-free low-temperature construction comprises the following steps:

[0028] 1. Prepare raw materials;

[0029] 2. Put 70# petroleum asphalt and liquid rosin resin into the batching tank and heat to 130°C, add SBS1301 and SBR powder, heat up to 165°C, and stir for 60 minutes to swell;

[0030] 3. Add polyethylene wax, keep the temperature at 165°C, stir and swell for 20 minutes;

[0031] 4. After passing through the colloid mill, add stone powder, keep the temperature at 120°C, and stir for 60 minutes.

Embodiment 2

[0033] A method for making a non-cured rubber asphalt waterproof coating for oil-free low-temperature construction, comprising the following steps:

[0034] 1. Prepare raw materials;

[0035] 2. Put 90# petroleum asphalt and liquid rosin resin into the batching tank and heat to 140°C, add SBS1301 and SBR powder, heat up to 175°C, and stir for 40 minutes to swell;

[0036] 3. Add SASOBIT asphalt additive, keep the temperature at 175°C, stir and swell for 25 minutes;

[0037] 4. After passing through the colloid mill, add stone powder, keep the temperature at 125°C, and stir for 50 minutes.

Embodiment 3

[0039] A method for making a non-cured rubber asphalt waterproof coating for oil-free low-temperature construction, comprising the following steps:

[0040] 1. Prepare raw materials;

[0041] 2. Put 90# petroleum asphalt and liquid rosin resin into the batching tank and heat to 145°C, add butyl rubber, SBS1301 and SBR powder, heat up to 180°C, and stir for 40 minutes to swell;

[0042] 3. Add polyethylene wax, keep the temperature at 180°C, stir and swell for 25 minutes;

[0043] 4. After passing through the colloid mill, add talcum powder, keep the temperature at 125°C, and stir for 45 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com