Smokeless non-curing rubber asphalt waterproof coating capable of low temperature construction and production method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the field of asphalt waterproof coating to achieve the effect of realizing energy saving and environmental protection, shortening heating time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

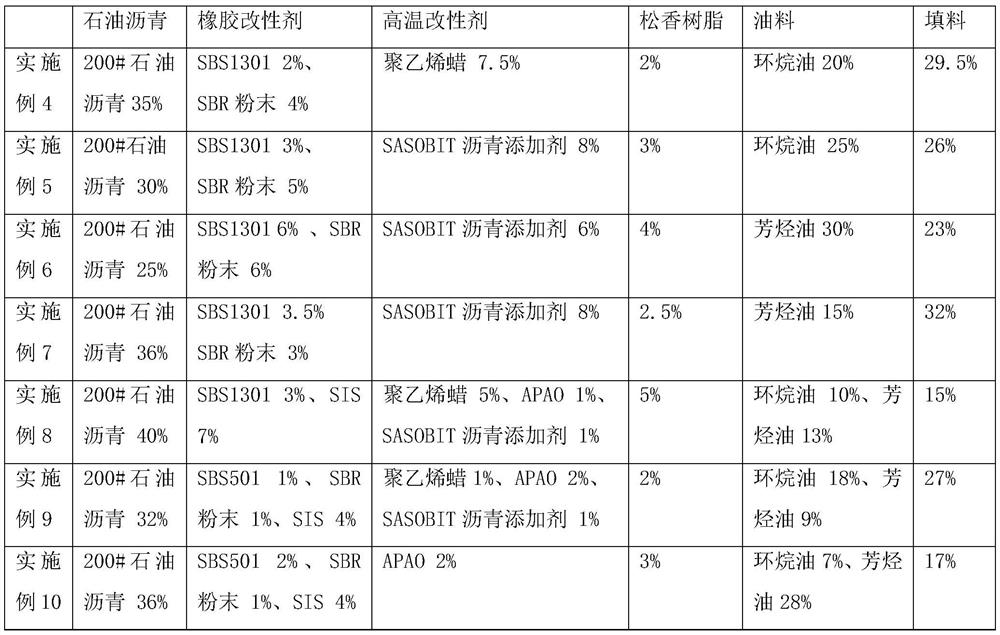

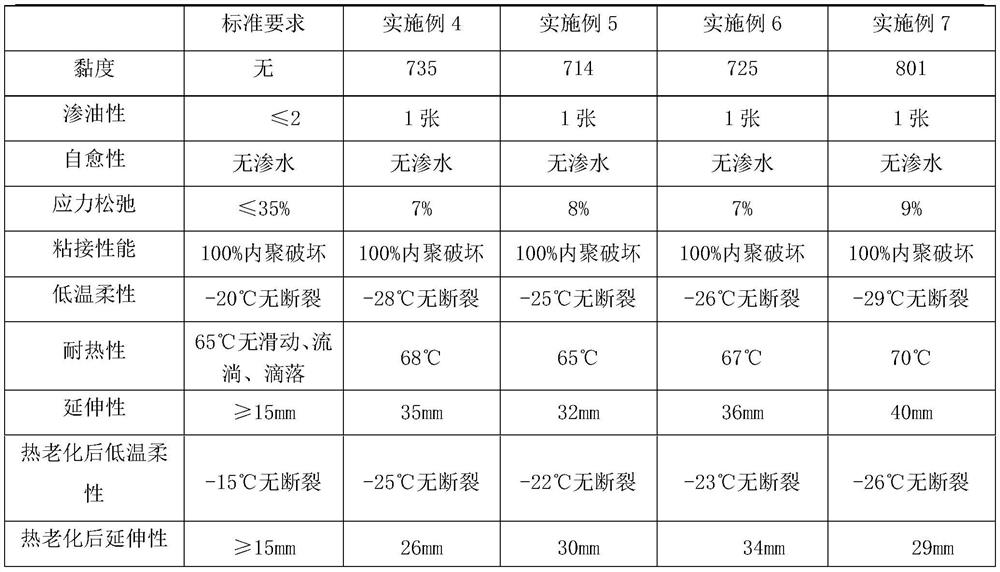

Examples

Embodiment 1

[0025] Stir 50 parts of heavy calcium carbonate at 75°C, add 1 part of aluminate coupling agent, continue stirring for 30-60 minutes, and obtain aluminate modified heavy calcium carbonate after cooling.

Embodiment 2

[0027] Stir 75 parts of heavy calcium carbonate at 85°C, add 1 part of aluminate coupling agent, continue stirring for 30-60 minutes, and obtain aluminate modified heavy calcium carbonate after cooling.

Embodiment 3

[0029] Stir 100 parts of heavy calcium carbonate at 80°C, add 1 part of aluminate coupling agent, continue stirring for 30-60 minutes, and obtain aluminate modified heavy calcium carbonate after cooling.

[0030] 2. Determination of activation rate

[0031] Take by weighing 5g of the aluminate-modified heavy calcium carbonate described in Example 1-3, its mass is recorded as m, put in a 250mL separating funnel, add 200mL of water, shake for 5min, then place on the funnel stand, Stand still for 30 minutes, after the obvious stratification, put the sinking calcium carbonate into the crucible filter which has been dried to constant weight at one time, remove the water by suction filtration, move into the constant temperature box, and dry to constant weight. The activation rate is represented by mass percentage, denoted as AD, and the specific calculation is: AD=(1-(m2-m1) / m)×100%, wherein: m2 is the mass (g) of the crucible and uncoated calcium carbonate after drying ; m1 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com