Preparation method of storage bit and preparation method of MRAM

A storage bit and magnetic tunnel junction technology, applied in the field of semiconductor memory chip manufacturing, can solve problems such as magnetic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] As introduced in the background art, the manufacturing process of storage bits in the prior art easily leads to magnetic damage of the device. In order to solve the above-mentioned technical problems, the applicant of the present invention provides a method for preparing a storage bit, including the step of forming a magnetic tunnel junction. After the step of forming a magnetic tunnel junction, the preparation method further includes the following steps: The junction sidewalls are gas passivated to reduce dangling bonds on their sidewall surfaces.

[0032] No matter what etching method is adopted, a large number of high-energy particles will irradiate the tunnel junction during etching, resulting in not only uneven surface and large specific surface area of the etched tunnel junction, but also chaotic surface lattice, dislocations, impurities, The vacancy density is high, the magnetic anisotropy of the surface area is not strong, and multi-domain inversion is prone t...

Embodiment 1

[0053] The method for preparing storage bits provided in this embodiment includes the following steps:

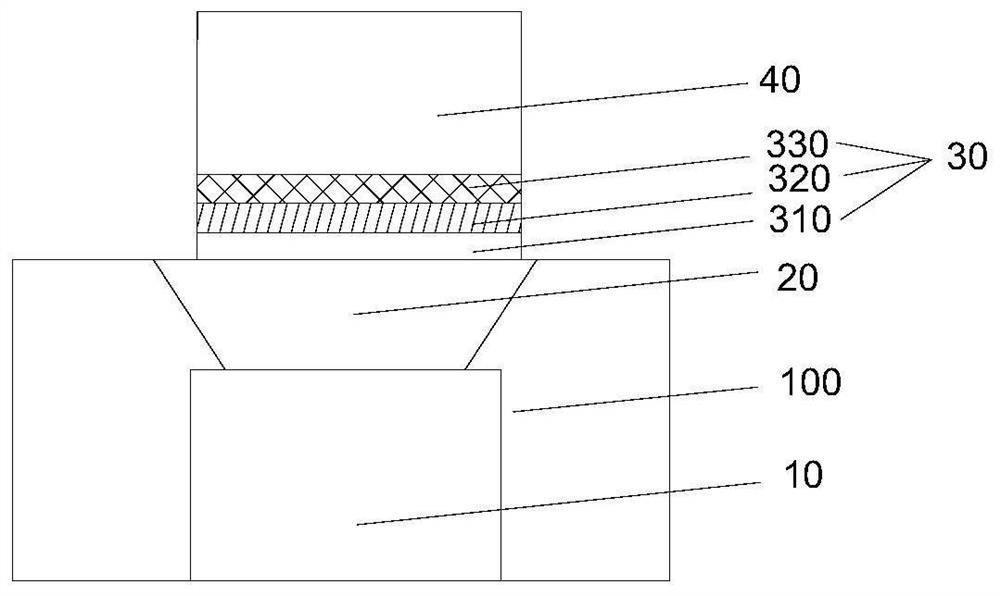

[0054] The second mask material layer 510 is deposited on the first mask material layer 410, and the photoresist 60 is covered on the second mask material layer 510, and the photoresist 60 is patterned by photolithography and developing processes, so as to The photoresist 60 is used as a mask to etch the second mask material layer 510 to obtain the second mask layer 50 with the same pattern as the photoresist 60, such as figure 1 with figure 2 shown; then through the second mask layer 50, the first mask material layer 410 is etched to transfer the pattern of the patterned photoresist 60 to obtain the first mask layer 40;

[0055] The tunnel junction material layer 301 is etched through the first mask layer 40 to form a magnetic tunnel junction 30, including a reference layer 310, a barrier layer 320 and a free layer 330, and the etching stays below the bottom electrode 20...

Embodiment 2

[0059] The difference between the method for preparing storage bits provided in this embodiment and that of Embodiment 1 is that:

[0060] The hydrogen flow rate is 10 sccm, the argon gas flow rate is 5000 sccm, the air pressure is 1 Torr, the power is 10 W, the temperature is 20° C., and the processing time is 500 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com