Preparation method of functionalized modified molybdenum disulfide nanosheet

A technology of molybdenum disulfide and nano-sheets, which is applied in the field of nano-materials, can solve problems such as organic covalent grafting and modification, and achieve the effects of facilitating lubrication, improving friction resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

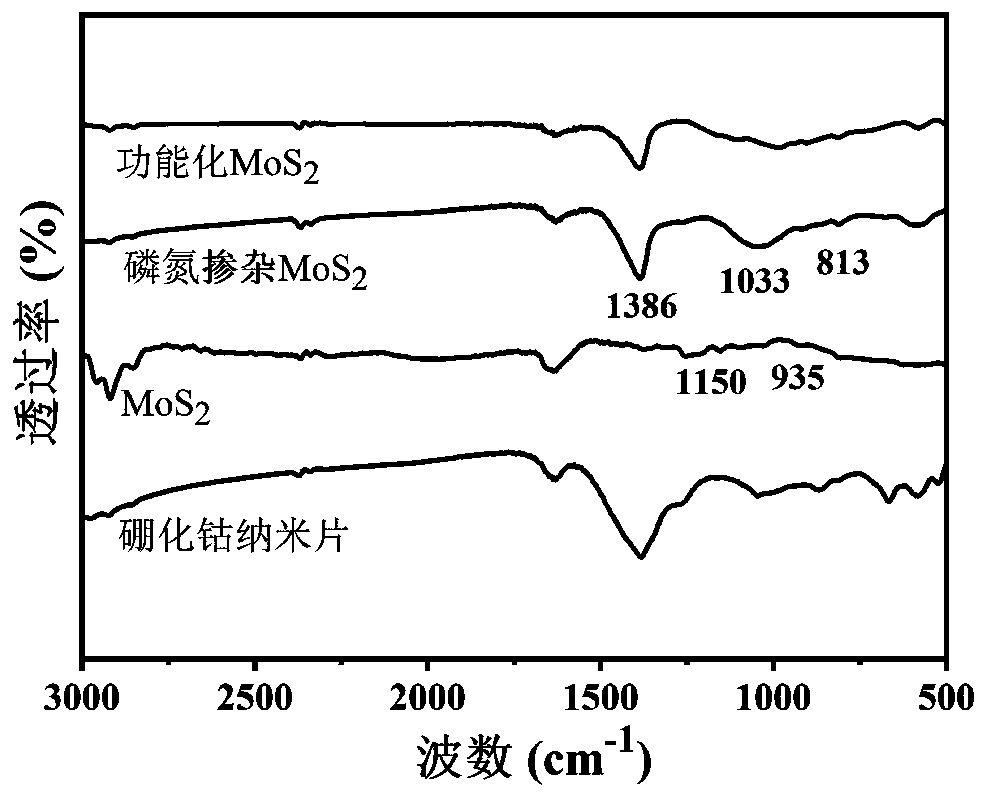

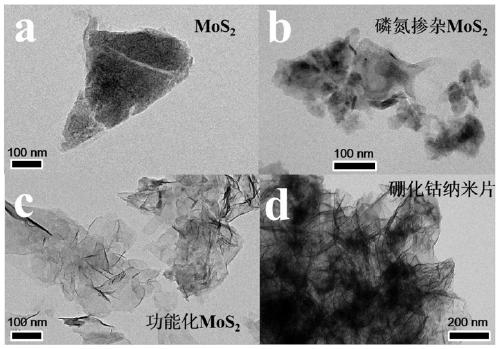

[0028] 1. Put molybdenum disulfide powder (1.0g), hexachlorocyclotriphosphazene (0.1g) and guanidine hydrochloride (0.2g) into a 100mL stainless steel ball mill jar with 60g stainless steel balls, fill it with nitrogen and seal it at 1400rpm The rotation speed lasts for 2h.

[0029] 2. Put 1.0g of the precursor into the quartz furnace, and set the system temperature at 5°C min -1 The heating rate was raised to 550°C, and then a 2h isothermal process was carried out. After the reaction is finished, after cooling to room temperature, the solid powder is collected and washed to prepare phosphorus and nitrogen-containing molybdenum disulfide nanosheets;

[0030] 3. Disperse the phosphorus-nitrogen-containing molybdenum disulfide nanosheets in deionized water, drop them into an aqueous solution of cobalt nitrate hexahydrate (0.02mol / L), and perform an in-situ reaction; the phosphorus-nitrogen-containing molybdenum disulfide sheets and Co 2+ After the electrostatic adsorption proc...

Embodiment 2

[0034] 1. Put molybdenum disulfide powder (0.5g), hexachlorocyclotriphosphazene (0.1g) and guanidine hydrochloride (0.1g) into a 100mL stainless steel ball mill jar with 60g stainless steel balls, fill it with nitrogen and seal it at 1400rpm The rotation speed lasts for 2h.

[0035] 2. Put 1.0g of the precursor into the quartz furnace, and set the system temperature at 7.5°C·min -1 The heating rate was increased to 550°C, and then an isothermal process was carried out for 2.5h. After the reaction is finished, after cooling to room temperature, the solid powder is collected and washed to prepare phosphorus and nitrogen-containing molybdenum disulfide nanosheets;

[0036] 3. Disperse the phosphorus-nitrogen-containing molybdenum disulfide nanosheets in deionized water, drop them into an aqueous solution of cobalt nitrate hexahydrate (0.02mol / L), and perform an in-situ reaction; the phosphorus-nitrogen-containing molybdenum disulfide sheets and Co 2+ After the electrostatic ads...

Embodiment 3

[0040] 1. Put molybdenum disulfide powder (0.25g), hexachlorocyclotriphosphazene (0.1g) and guanidine hydrochloride (0.15g) into a 100mL stainless steel grinding jar with 60g stainless steel balls, fill it with nitrogen and seal it at 1400rpm The rotation speed lasts for 2h.

[0041] 2. Put 1.0g of the precursor into the quartz furnace, and set the system temperature at 10°C min -1 The heating rate was raised to 550°C, and then a 3h isothermal process was carried out. After the reaction is finished, after cooling to room temperature, the solid powder is collected and washed to prepare phosphorus and nitrogen-containing molybdenum disulfide nanosheets;

[0042] 3. Disperse the phosphorus-nitrogen-containing molybdenum disulfide nanosheets in deionized water, drop them into an aqueous solution of cobalt nitrate hexahydrate (0.02mol / L), and perform an in-situ reaction; the phosphorus-nitrogen-containing molybdenum disulfide sheets and Co 2+ After the electrostatic adsorption pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com