Single-component epoxy resin composition and preparation method thereof

A technology of epoxy resin and composition, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of affecting production efficiency, peristaltic pump dripping, inconvenient automatic dripping paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

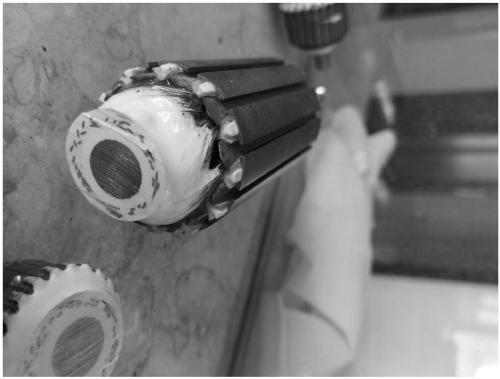

Image

Examples

Embodiment 1

[0096] 30 parts of bisphenol A type epoxy resin (CYD-128) with an epoxy equivalent of 185g / equivalent and a viscosity of 11000cps at 25°C, 2 parts of epoxy diluent hexanediol diglycidyl ether, 40 parts of filler 3000 mesh silica powder Parts, 20 parts of liquid methyl tetrahydrophthalic anhydride, 3 parts of thixotropic additives, unmodified hydrophilic fumed silicon dioxide Aerosil 200 with an average particle size of 12nm and 0.01 part of silicone defoamer were added to the mixing tank In the process, disperse at high speed at 1000rpm for 3 hours, pass cooling water to control the temperature of the mixture below 40°C, stop high-speed dispersion, keep stirring at 20rpm, when the temperature of the mixture drops below 25°C, add latent 1 under stirring at 20rpm part of curing accelerator 2,4-diamine-6-(2'-methylimidazolyl-(1'))-ethyltriazine-isocyanuric acid adduct powder (melting point>260°C), and then at 500rpm Disperse at high temperature for 2 hours, cool down with cold wa...

Embodiment 2

[0098] 30 parts of bisphenol F-type epoxy resin (NPEF-170) with an epoxy equivalent of 170g / equivalent and a viscosity of 3500cps at 25°C, 1 part of epoxy diluent hexanediol diglycidyl ether, and an inorganic filler with a particle size of 30 Add 40 parts of micron aluminum hydroxide, 22 parts of liquid methyl tetrahydrophthalic anhydride, 2 parts of GARAMITE-7305 organic bentonite which does not require pre-activation as a thixotropic additive, and 0.01 part of silicone defoamer into the mixing tank, and disperse at a high speed at 1000rpm For 3 hours, pass cooling water to control the temperature of the mixture below 40°C, stop the high-speed dispersion, and keep stirring at 20rpm. After the temperature of the mixture drops below 25°C, add 1 part of latent curing accelerator microcapsules to seal imidazole at 20rpm, Then disperse at 500rpm for 2 hours, cool down with cold water to ensure that the temperature of the mixture is lower than 30°C, and finally stir and defoam under...

Embodiment 3

[0100] 20 parts of novolac polyglycidyl ether (viscosity 5000cps@66°C) with an epoxy equivalent of 180g / equivalent, bisphenol F type epoxy resin NPEF-170 with an epoxy equivalent of 170g / equivalent and a viscosity of 3500cps at 25°C 10 parts, 2 parts of epoxy diluent butanediol diglycidyl ether, 40 parts of glass powder with filler particle size of 30 microns, 20 parts of liquid methylnadic anhydride, thixotropic additive dimethyl dichlorosilane modification Add 2 parts of hydrophobic fumed silica with an average particle size of 12nm and 0.01 part of silicone defoamer into the mixing tank, disperse at 1000rpm for 3 hours at high speed, pass cooling water to control the temperature of the mixture below 40°C, stop Disperse at high speed, keep stirring at 20rpm, when the temperature of the mixture drops below 25°C, add 3 parts of latent curing accelerator boron trifluoride ethylamine complex under stirring at 20rpm, then disperse at 500rpm for 2 hours, pass Lower the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com