Planar quick-start heater assembly and preparation method thereof

A planar and component technology, applied in the field of planar fast-start thermal sub-components and preparation, can solve the problems of insufficient heating efficiency and reliability, and achieve the effects of improving quick start-up time, increasing cross-sectional area, and reducing net volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

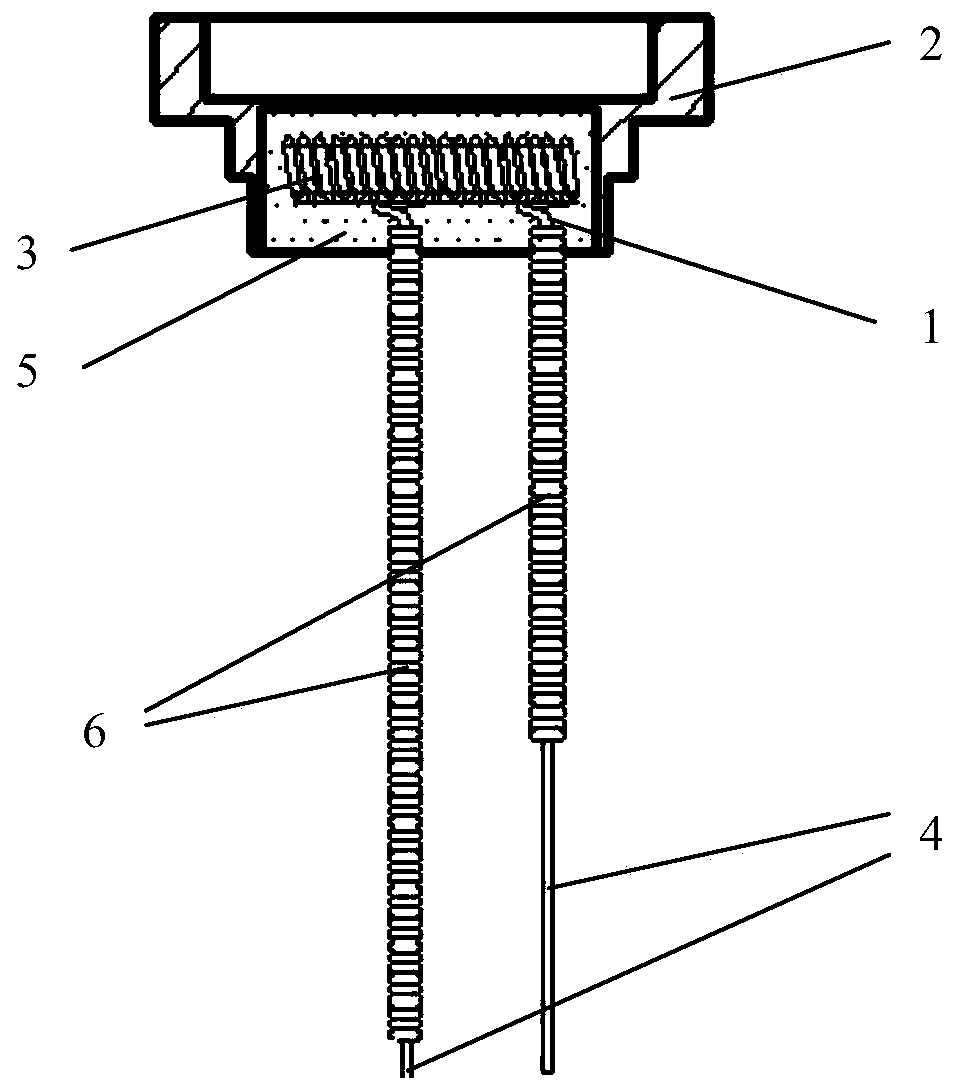

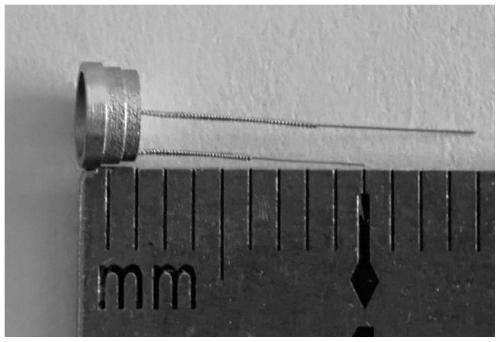

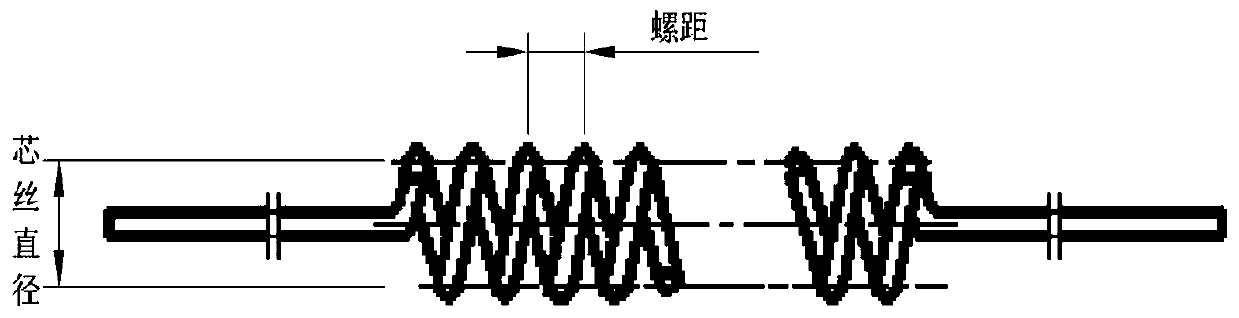

[0030] (a) A single-helix hot wire blank is wound on a hot wire machine, and its structure schematic diagram is as follows image 3 As shown, the diameter of the core wire is 0.4mm, the winding diameter is 0.09mm, the pitch of the single helix is 0.2mm, and the number of turns of the blank is 35;

[0031] (b) Use a pressure of 20MPa on the hydraulic press to press the hot wire blank into a flat shape;

[0032] (c) Winding the flat heating wire blank on the heating wire mold to form a plane e-shaped structure heating wire, leaving the heating wire legs at both ends to obtain the heating wire body;

[0033] (d) Shape the hot wire body in a hydrogen furnace at a temperature of 1500°C for 25 minutes;

[0034] (e) dilute the hot wire body after shaping with sulfuric acid and nitric acid to remove the core wire in a certain proportion, and tightly wind the spring on the hot wire leg;

[0035] (f) attaching a layer of aluminum oxide insulating layer on the surface of the heating ...

Embodiment 2

[0038] (a) Winding a single helical hot wire blank on a hot wire machine, wherein the diameter of the core wire is 0.45 mm, the winding diameter is 0.10 mm, the pitch of the single helix is 0.25 mm, and the number of turns of the blank is 37;

[0039] (b) Use a pressure of 25MPa on the hydraulic press to press the hot wire blank into a flat shape;

[0040] (c) Winding the flat heating wire blank on the heating wire mold to form a plane e-shaped structure heating wire, leaving the heating wire legs at both ends to obtain the heating wire body;

[0041] (d) Shape the hot wire body in a hydrogen furnace at a temperature of 1550°C for 20 minutes;

[0042] (e) dilute the hot wire body after shaping with sulfuric acid and nitric acid to remove the core wire in a certain proportion, and tightly wind the spring on the hot wire leg;

[0043] (f) using the electrophoresis method to attach a layer of aluminum oxide insulation layer on the surface of the hot wire with the hot wire body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com