Method for constructing super-hydrophobic coating on surface of copper alloy in situ

A technology of super-hydrophobic coating and copper alloy, which is applied in the direction of metal material coating technology, etc., can solve the problems that the invention has not been reported, and achieve the effect of strong binding force, strong practicability and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

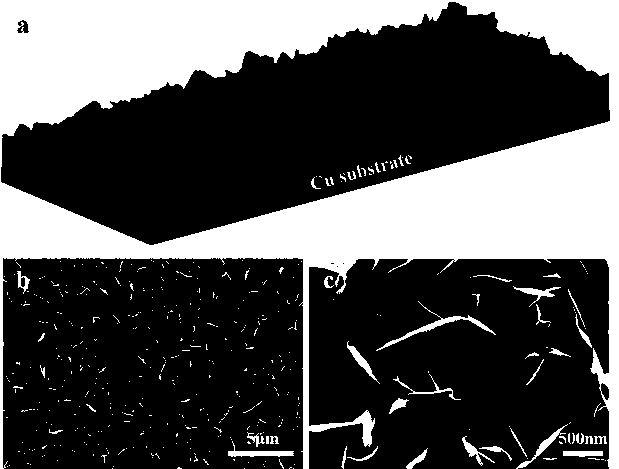

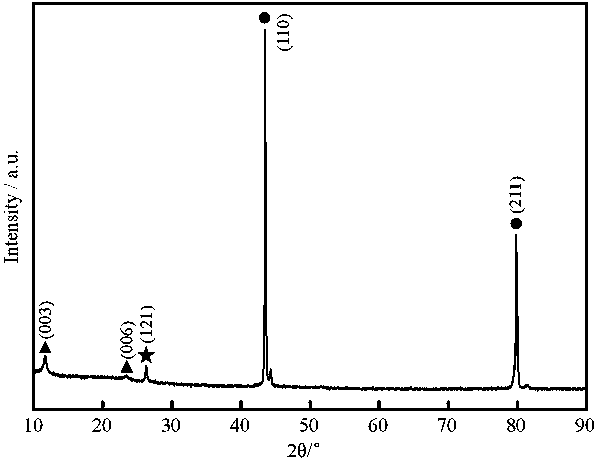

[0042] In this embodiment, a method for constructing a superhydrophobic coating in situ on the surface of a copper alloy comprises the following steps:

[0043] a. Copper alloy surface pretreatment:

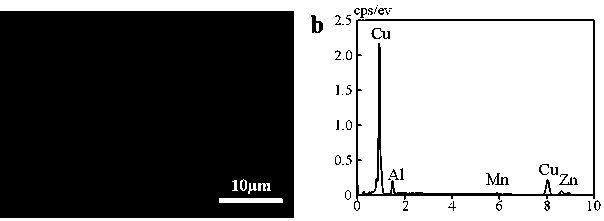

[0044] The aluminum-brass alloy of copper with high aluminum content is used as the base material of the copper alloy, which contains 25.09% zinc, 5.89% aluminum, 1.48% manganese, 0.40% iron, and the rest is copper; the copper alloy is cut and grown, A small piece of copper alloy material with an arbitrary size of 10mm×10mm×5mm in width and height, using SiC sandpaper with a particle size of 240 mesh, 600 mesh, 800 mesh, 2000 mesh, 5000 mesh and 7000 mesh, and using SiC sandpaper of different particle sizes in sequence Grinding, and then polishing the surface of the copper alloy material with a diamond suspension with a particle size of 0.5 μm, then cleaning the surface of the copper alloy material with deionized water, and then ultrasonically cleaning the copper alloy material i...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, especially in that:

[0054] In this embodiment, a method for constructing a superhydrophobic coating in situ on the surface of a copper alloy comprises the following steps:

[0055] a. Copper alloy surface pretreatment:

[0056] The aluminum-brass alloy of copper with high aluminum content is used as the base material of the copper alloy, which contains 25.09% zinc, 5.89% aluminum, 1.48% manganese, 0.40% iron, and the rest is copper; the copper alloy is cut and grown, A small piece of copper alloy material with an arbitrary size of 10mm×10mm×5mm in width and height, using SiC sandpaper with a particle size of 240 mesh, 600 mesh, 800 mesh, 2000 mesh, 5000 mesh and 7000 mesh, and using SiC sandpaper of different particle sizes in sequence Grinding, and then polishing the surface of the copper alloy material with a diamond suspension with a particle size of 0.5 μm, then cleaning the surface of the copper alloy materi...

Embodiment 3

[0069] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0070] a. Copper alloy surface pretreatment:

[0071] Brass is used as the base material, the mass fraction of zinc is 30%, and the rest is copper; the brass is cut into small pieces of brass with any size of 10mm×10mm×5mm in length, width and height, and the particle size is 240 mesh, 600 Mesh, 800 mesh, 2000 mesh, 5000 mesh and 7000 mesh SiC sandpaper, use SiC sandpaper of different particle sizes to polish in turn, and then use a diamond suspension with a particle size of 0.5 μm to polish the surface of the brass, and then use deionized water Clean the brass surface, then ultrasonically clean the brass in ethanol solution and deionized water for 5 minutes, and then dry it with cold air to obtain clean and dry brass with surface pretreatment, and set aside;

[0072] b. The process of in-situ construction of layered double hydroxide / oxide multi-level structure film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com