Amphiphilic graphene quantum dot material, preparation method thereof, fluorescent coding anti-counterfeiting ink based on the material and preparation method of the ink

A technology of graphene quantum dots and fluorescent encoding, which is applied in the nanometer field, can solve the problems that the product is difficult to dissolve in various solvents, the preparation process is cumbersome, and the application is limited, so as to achieve good controllability, simplify the preparation steps, and reduce the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

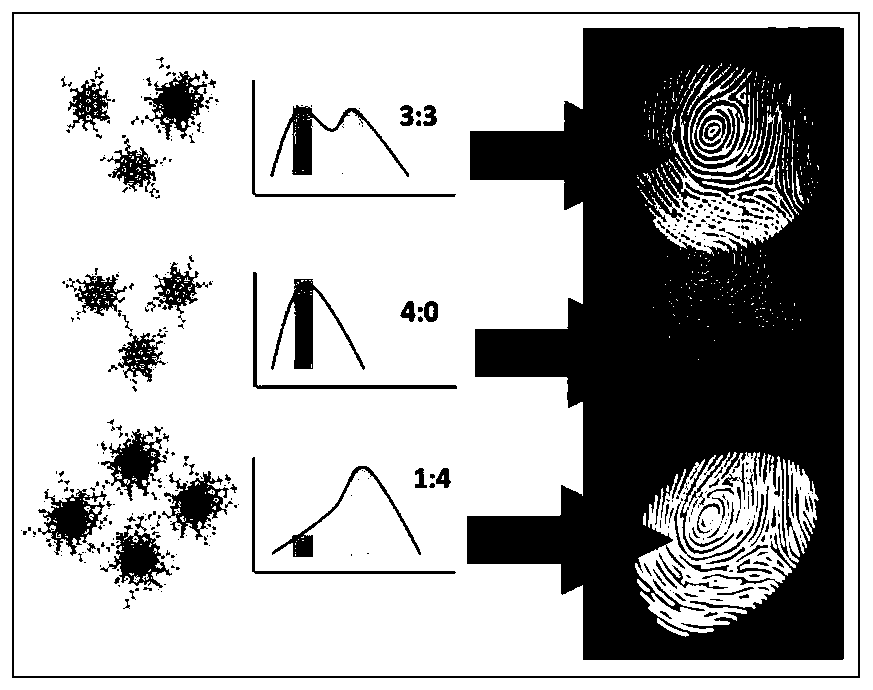

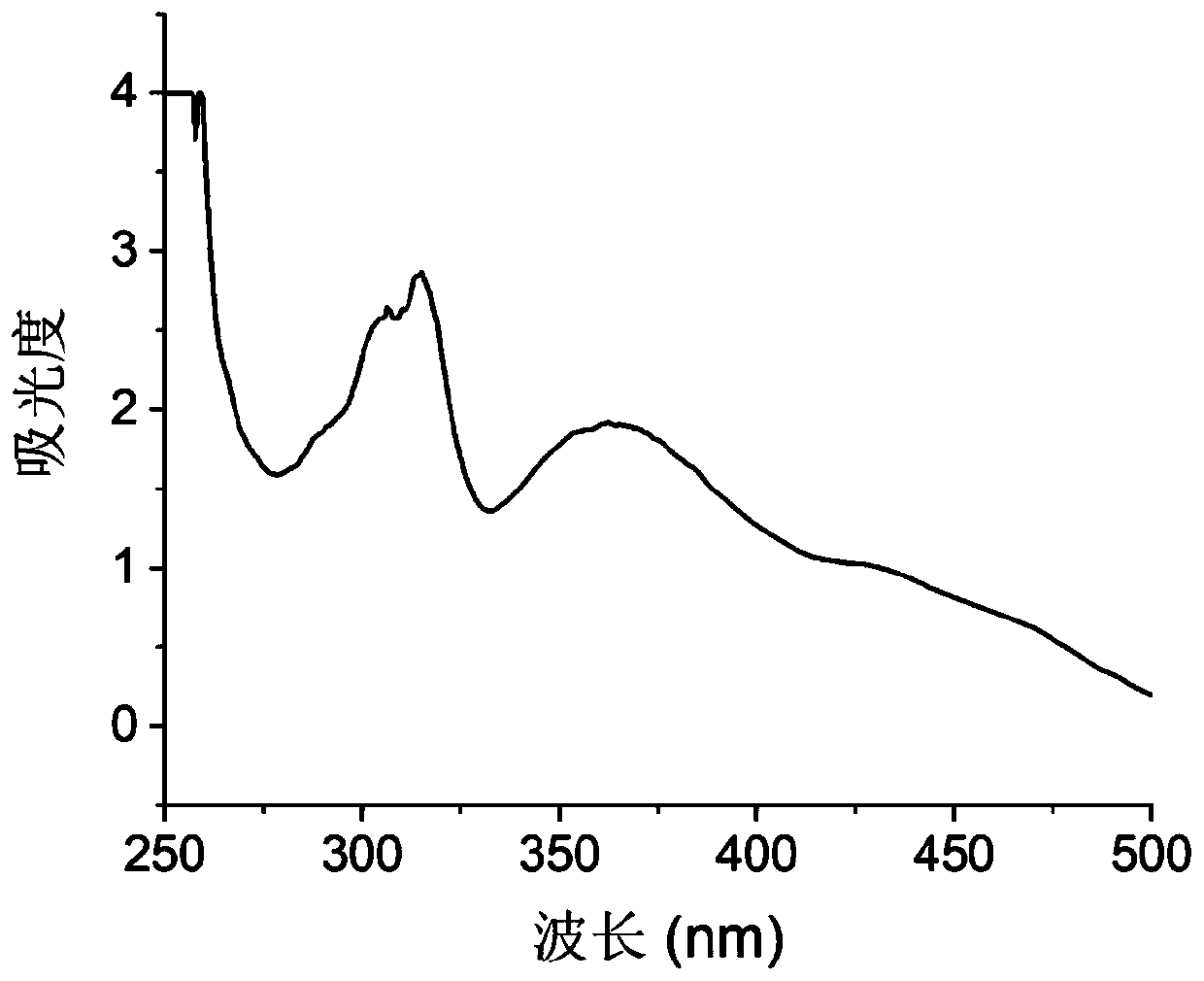

[0049] Weigh 1.60g of acetyl triethyl citrate, 0.75g of aminobutanol, (the molar ratio is 1:1.7), mix thoroughly, place in a 20mL glass microwave reaction tube, and control the reaction under 2.45GHz, 700W microwave irradiation conditions React at a temperature of 300°C for 3 minutes to obtain a crude product of amphiphilic graphene quantum dots. After cooling to room temperature, 4 mL of ethanol was added to the microwave reaction tube, and the product was completely dispersed by ultrasonic treatment. The ethanol dispersion of the prepared graphene quantum dots was transferred to a 50mL centrifuge tube, and 20mL of ethyl acetate was added therein to precipitate the graphene quantum dots from the ethanol-ethyl acetate mixed solution. The obtained product was centrifuged and precipitated, and the supernatant was removed by decanting, and 4 mL of ethanol was added to the precipitate, and the precipitate was dispersed in ethanol again by ultrasonic dispersion. The precipitate wa...

Embodiment 2

[0057] Weigh 1.60g of acetyl triethyl citrate, 2.24g of aminobutanol, (molar ratio is 1:5), mix thoroughly, place in a 20mL glass microwave reaction tube, and control the reaction under 2.45GHz, 700W microwave irradiation conditions React at a temperature of 300°C for 3 minutes to obtain a crude product of amphiphilic graphene quantum dots. After cooling to room temperature, 4 mL of ethanol was added to the microwave reaction tube, and the product was completely dispersed by ultrasonic treatment. The ethanol dispersion of the prepared graphene quantum dots was transferred to a 50mL centrifuge tube, and 20mL of ethyl acetate was added therein to precipitate the graphene quantum dots from the ethanol-ethyl acetate mixed solution. The obtained product was centrifuged and precipitated, and the supernatant was removed by decanting, and 4 mL of ethanol was added to the precipitate, and the precipitate was dispersed in ethanol again by ultrasonic dispersion. The precipitate was wash...

Embodiment 3

[0060] Weigh 1.60g of acetyl triethyl citrate, 0.75g of aminobutanol (molar ratio is 1:1.7), mix thoroughly, place in a 20mL glass microwave reaction tube, and control the reaction under 2.45GHz, 700W microwave irradiation conditions React at a temperature of 300°C for 3 minutes to obtain a crude product of amphiphilic graphene quantum dots. After cooling to room temperature, 4 mL of ethanol was added to the microwave reaction tube, and the product was completely dispersed by ultrasonic treatment. The ethanol dispersion of the prepared graphene quantum dots was transferred to a 50mL centrifuge tube, and 20mL of ethyl acetate was added therein to precipitate the graphene quantum dots from the ethanol-ethyl acetate mixed solution. The obtained product was centrifuged and precipitated, and the supernatant was removed by decanting, and 4 mL of ethanol was added to the precipitate, and the precipitate was dispersed in ethanol again by ultrasonic dispersion. The precipitate was was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com