Preparation method of core-shell structure loaded catalyst

A supported catalyst and core-shell structure technology, applied in the field of catalysis, can solve problems such as weak shell-like structure, and achieve the effect of repairing lattice defects, stabilizing the overall structure, and good particle dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

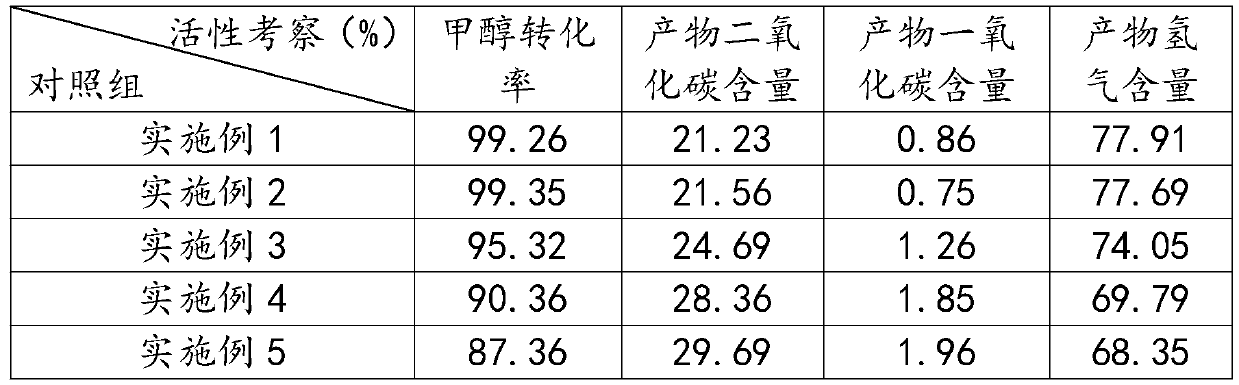

Examples

Embodiment 1

[0038] The preparation method of core-shell structure supported catalyst comprises the steps:

[0039] The first step, preparation of iron oxide hollow spheres:

[0040] Add 30g of tetraethyl orthosilicate into a beaker filled with 20g of absolute ethanol for stirring, slowly add 10g of ammonia water dropwise, after the dropwise addition is completed, continue to stir for 2-3 hours, perform centrifugation, suction filtration, washing, and then put it in an oven Fully dry at 60-80°C for 10-15h, transfer to a muffle furnace and bake at 400-500°C for 2-3h, cool to room temperature, and grind into powder to obtain silica nanospheres; add silica nanospheres into In a beaker of 20g of absolute ethanol, ultrasonically treat for 2-3 hours to form a silica suspension; add 30g of ferric nitrate to the silica suspension and stir evenly, slowly add 10g of ammonia water dropwise, and continue stirring for 2- 3h, then add 10g of 0.5mol / L hydrofluoric acid aqueous solution, stir for 0.5-1h,...

Embodiment 2

[0050] The preparation method of core-shell structure supported catalyst comprises the steps:

[0051] The first step, preparation of iron oxide hollow spheres:

[0052] Add 40g of tetraethyl orthosilicate into a beaker filled with 25g of absolute ethanol for stirring, slowly add 15g of ammonia water dropwise, after the dropwise addition is completed, continue to stir for 2-3 hours, perform centrifugation, suction filtration, washing, and then put it in an oven Fully dry at 60-80°C for 10-15h, transfer to a muffle furnace and bake at 400-500°C for 2-3h, cool to room temperature, and grind into powder to obtain silica nanospheres; add silica nanospheres into In a beaker of 25g of absolute ethanol, ultrasonically treat for 2-3 hours to form a silica suspension; add 40g of ferric nitrate to the silica suspension and stir evenly, slowly add 15g of ammonia water dropwise, and continue stirring for 2- 3h, then add 20g of 0.5mol / L hydrofluoric acid aqueous solution, stir for 0.5-1h,...

Embodiment 3

[0062] In Example 2, the composite template was replaced with a single template of triethylamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com