Two-component acrylate structure adhesive with high strength and excellent stability and preparation method of two-component acrylate structure adhesive

A structural adhesive and high-strength technology, applied in the direction of acrylonitrile butadiene styrene polymer adhesives, adhesives, epoxy resin adhesives, etc., to achieve excellent process performance, excellent aging resistance, and short heating and curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

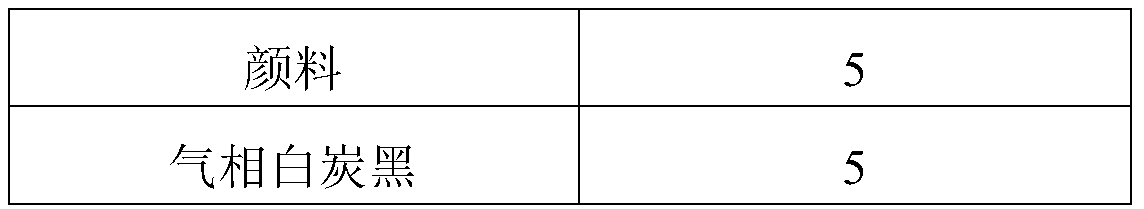

[0061] The acrylic type monomer of A component selects methyl methacrylate, stearic acid acrylate, urethane acrylate; the toughening agent selects ABS resin and MBS resin; the stabilizer selects hydroquinone and ethylenediamine Disodium tetraacetate; the accelerator is selected from triphenylphosphine; the reducing agent is selected from ethylenediamine; the other auxiliary agents are selected from pigments and fumed white carbon black. The specific component contents are shown in Table 1.

[0062] Table 1:

[0063]

[0064]

[0065] The epoxy resin of component B selects bisphenol A type 828; the graphene derivative selects graphene oxide; the plasticizer selects dibutyl phthalate; the oxidant selects benzoyl peroxide; The polymerization inhibitor is selected from hydroquinone; the composite coupling agent is selected from bis-(3-triethoxysilylpropyl)amine and ν-glycidoxypropyltrimethylsilane. The specific component contents are shown in Table 2.

[0066] Table 2:

...

Embodiment 2

[0069] The acrylic type monomer of A component selects methyl methacrylate, cyclohexyl methacrylate, trimethylolpropane triacrylate; the toughening agent selects ABS resin and SEBS resin; the stabilizer selects p-benzene Quinone and polyphosphoric acid; the accelerator selects triphenylphosphine and magnesium methacrylate; the reducing agent selects N, N-diethyl-p-toluidine; the other auxiliary agents select pigment, nylon powder and fumed white carbon black. The specific component contents are shown in Table 3.

[0070] table 3:

[0071]

[0072]

[0073] The epoxy resin of component B selects bisphenol A type 828; the graphene derivative selects graphene phosphate; the plasticizer selects diisobutyl phthalate; the oxidant selects benzoyl peroxide ; The polymerization inhibitor selects p-benzoquinone; the composite coupling agent selects 3-aminopropylmethyldiethoxysilane and ν-glycidoxypropyl trimethylsilane. The specific component contents are shown in Table 4.

[...

Embodiment 3

[0077] The acrylic type monomer of A component selects methyl methacrylate, octyl methacrylate, polyethylene glycol dimethacrylate; the toughening agent selects ABS resin and MBS resin; the stabilizer selects 2, 6-di-tert-butyl-p-cresol and tetrasodium ethylenediaminetetraacetic acid; the accelerator is triphenylphosphine; the reductant is N, N-dimethylaniline; Fumed silica. The specific component contents are shown in Table 5.

[0078] table 5:

[0079] A component raw material Component Methyl methacrylate 32 Octyl methacrylate 10 polyethylene glycol dimethacrylate 10 ABS resin 18 MBS resin 15 2,6-di-tert-butyl-p-cresol 1.5 Tetrasodium EDTA 0.5 Triphenylphosphine 1.0 N,N-Dimethylaniline 2 pigment 3 Fumed silica 7

[0080] The epoxy resin of component B selects bisphenol A type 828; the graphene derivative selects graphene phosphate; the plasticizer selects butyl benzyl phthalate; the oxidant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com