Crystalline polyaryletherketone nanofiber membrane and preparation method and application thereof

A nanofiber membrane, polyaryletherketone technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problem of difficult to control fiber diameter and porosity, polymer loss of polyetheretherketone crystallinity, and increase process cost. and operation difficulty, etc., to achieve the effects of low cost of raw materials, excellent mechanical properties, and simple and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

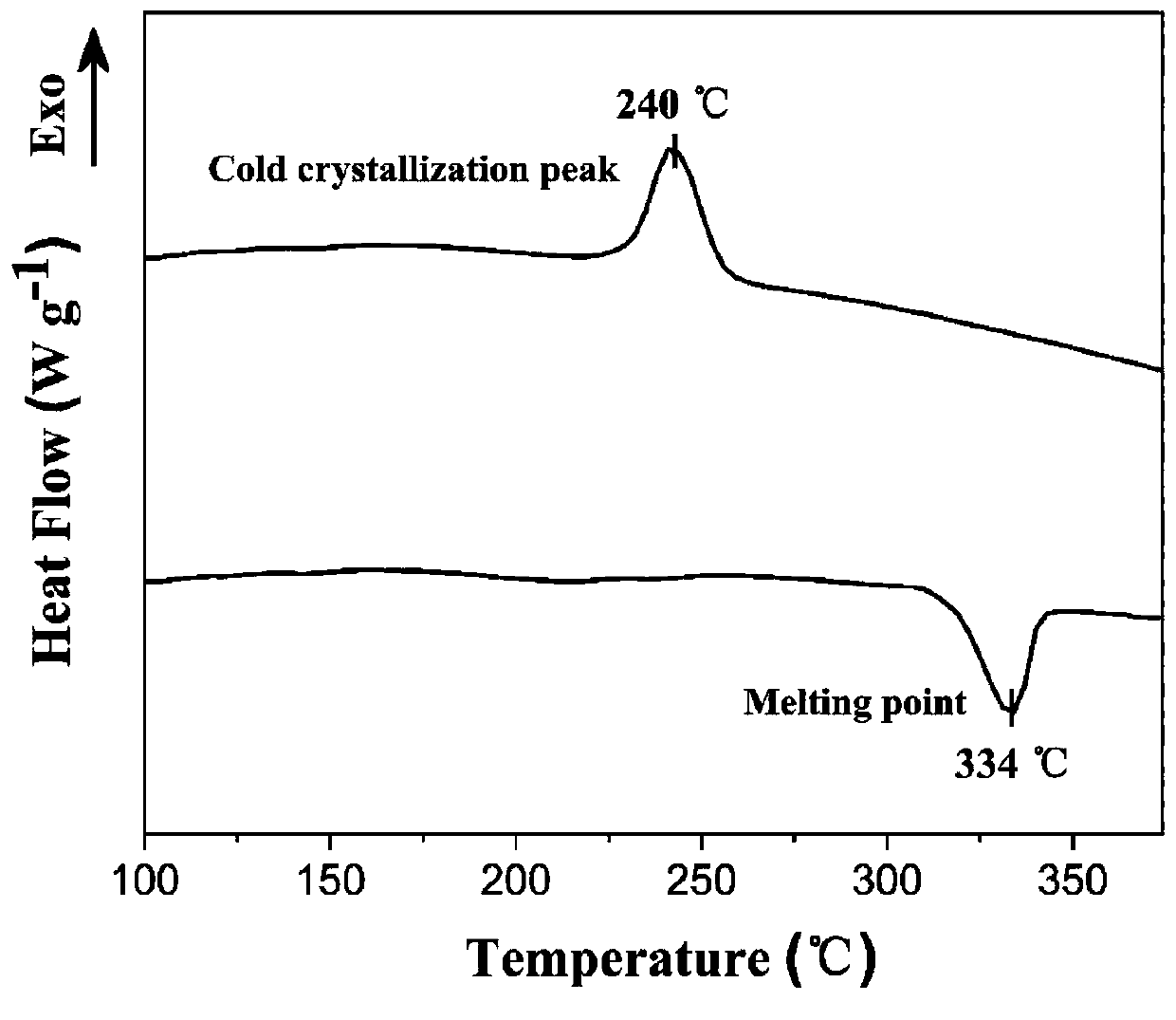

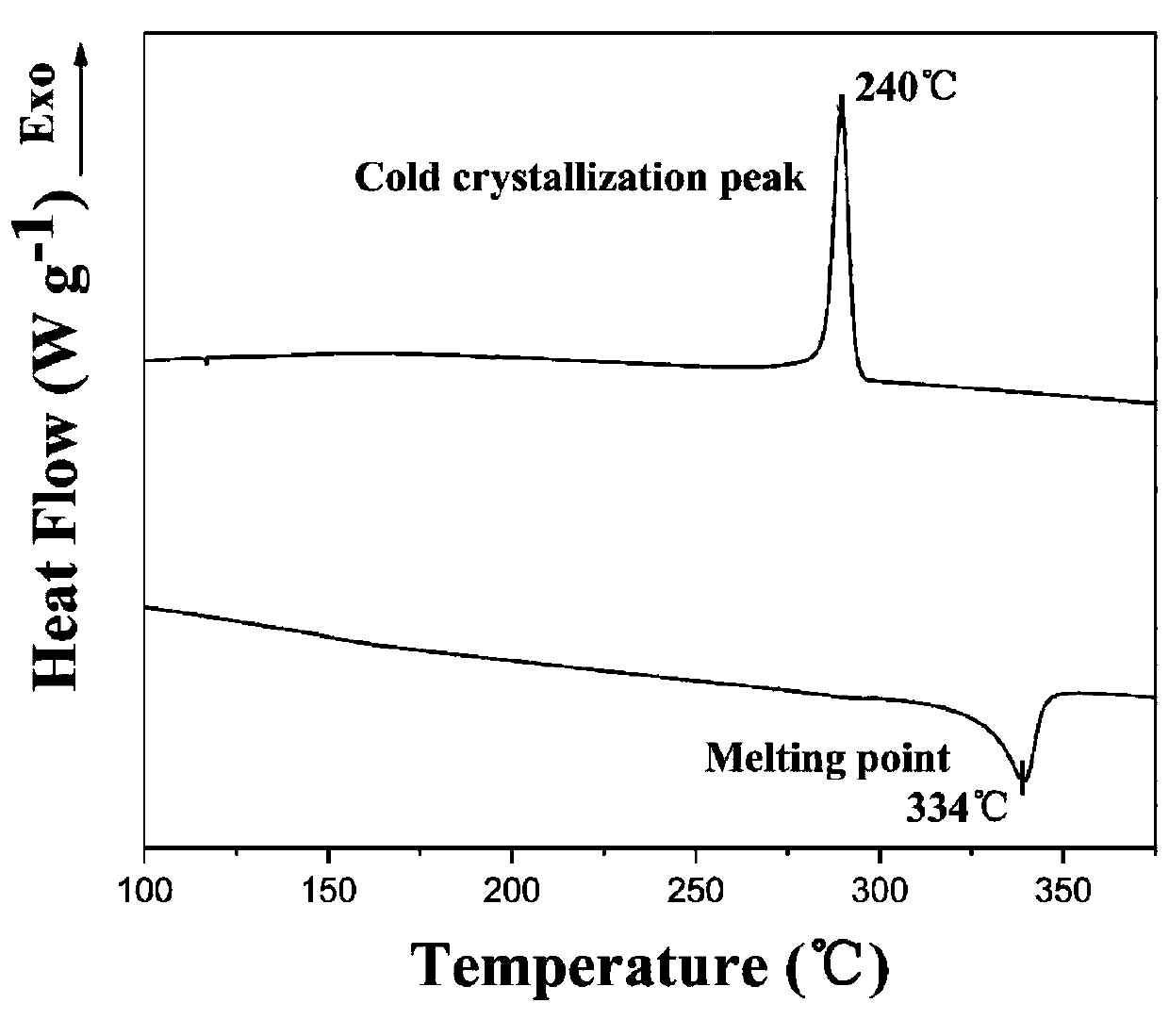

[0035] The soluble polyetheretherketone precursor: polyetheretherketone-1,3-dioxolane (see literature [1,2] for its preparation method) (1.0g) was dissolved in a good solvent for polar polymer NMP (4mL) In the solution, the mass concentration of the solution is 20%, and the solution is airtightly stirred for 15 hours at room temperature to prepare a clear and transparent spinning solution; the spinning solution is installed in the syringe of the electrostatic spinning device, the syringe needle is connected to the positive electrode of the high-voltage power supply, and the aluminum foil is received The plate is connected to the negative electrode of the high-voltage power supply for spinning, and the prepared nanofiber membrane is formed on the aluminum foil receiving plate; the distance between the syringe needle and the surface of the aluminum foil receiving plate is 15cm, the applied voltage is 15kV, and the syringe advancing speed is 0.2mL / h . The obtained nanofiber membra...

Embodiment 2

[0038] The preparation process of the crystalline polyetheretherketone nanofiber membrane described in Example 1 is the same, except that the prepared crystalline polyetheretherketone nanofiber membrane is assembled into a supercapacitor for cyclic voltammetric curve test according to document [4]. The electrochemical workstation (CHI 660A) is in the voltage range of 0.0~3.0V, and the scan rate is 5 mV s -1 , Test at ambient temperature.

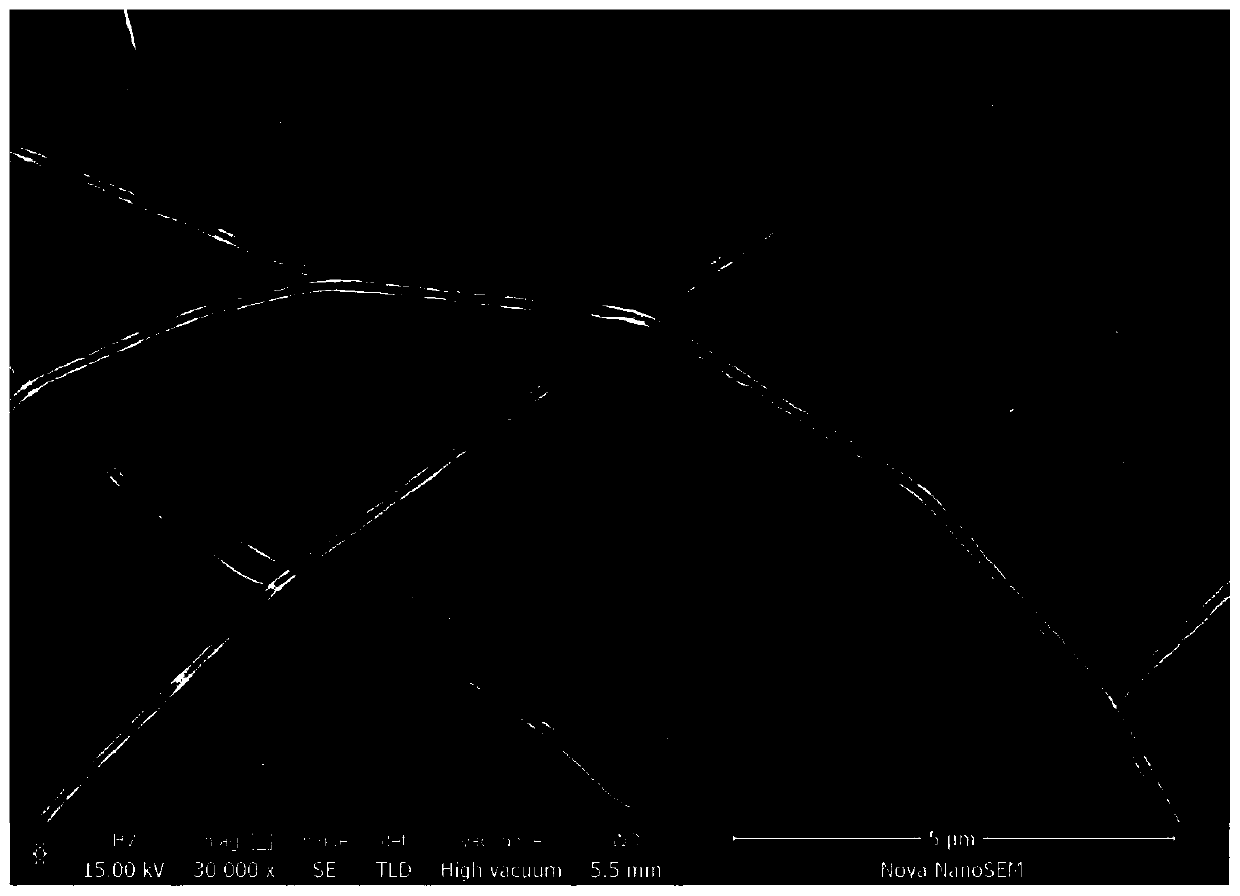

[0039] The SEM picture of the polyetheretherketone nanofiber membrane obtained by the reduction of polyetheretherketone-1,3-dioxolane prepared in Example 2 is attached. image 3 The figure shows the successful preparation of nanofiber membranes, where the fiber diameter is 110nm and the membrane thickness is 10μm. The linear sweep voltammetry curves of the conventional gel electrolyte (GPE-20) and cross-linked gel electrolyte (NGPE-CL-20) of the supercapacitor prepared in Example 2 are shown in the attachment Image 6 ; The figure shows that bot...

Embodiment 3

[0041] The preparation process of the crystalline polyether ether ketone nanofiber membrane is the same as in Example 1, except that the prepared crystalline polyether ether ketone nanofiber membrane is assembled into a lithium ion button battery according to document [5] to test the cycle performance. Use a potentiostat (Solartron Analytical) to test at 3C and 55°C.

[0042] The SEM picture of the polyetheretherketone nanofiber membrane obtained by the reduction of polyetheretherketone-1,3-dioxolane prepared in Example 3 is attached. image 3 The figure shows the successful preparation of nanofiber membranes, where the fiber diameter is 110nm and the membrane thickness is 10μm. The rate performance of the lithium ion battery separator (PEEK) prepared in Example 3 and the commercial lithium ion battery separator (Cel 2325) is shown in the attachment Figure 7 The figure shows that the battery assembled with polyetheretherketone membrane has better rate performance than commercial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com