A kind of crystalline polyaryletherketone porous membrane with adjustable pore size, preparation method and application thereof

A technology of polyaryletherketone and polyaryletherketimine, which is applied in the field of preparation of crystalline polyaryletherketone porous membranes, can solve the problems of affecting comprehensive performance, unstable diluent, solvent resistance and high temperature, and achieves The preparation process is simple and easy, the cost of raw materials can be recovered, and the cost of raw materials is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

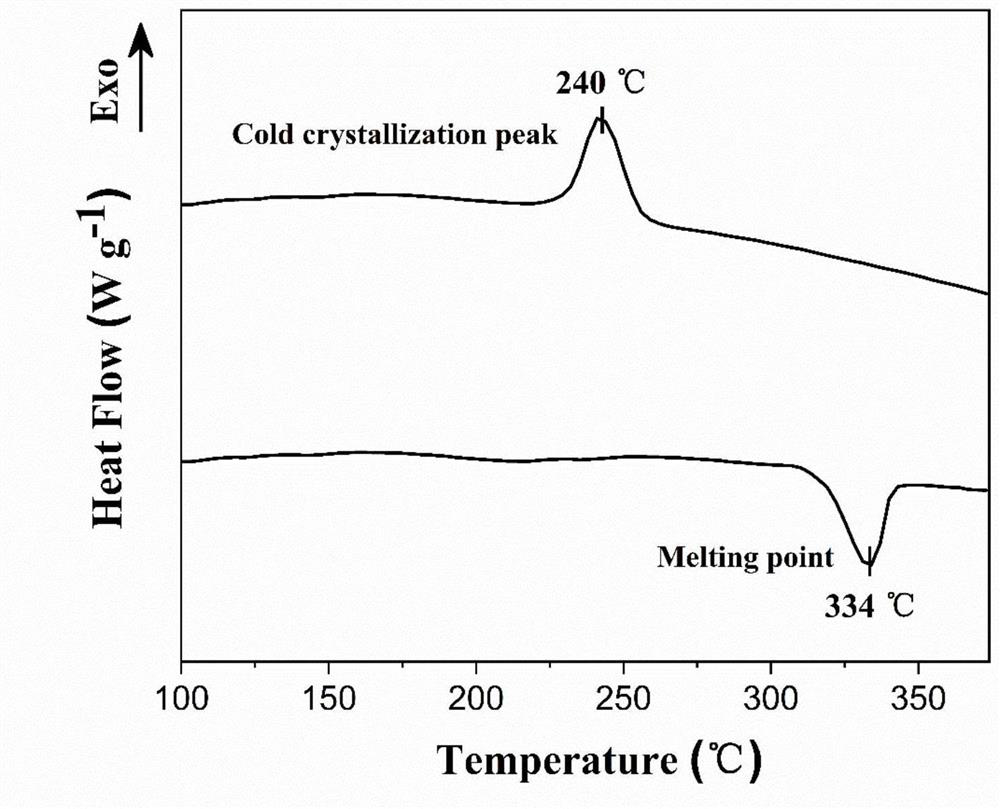

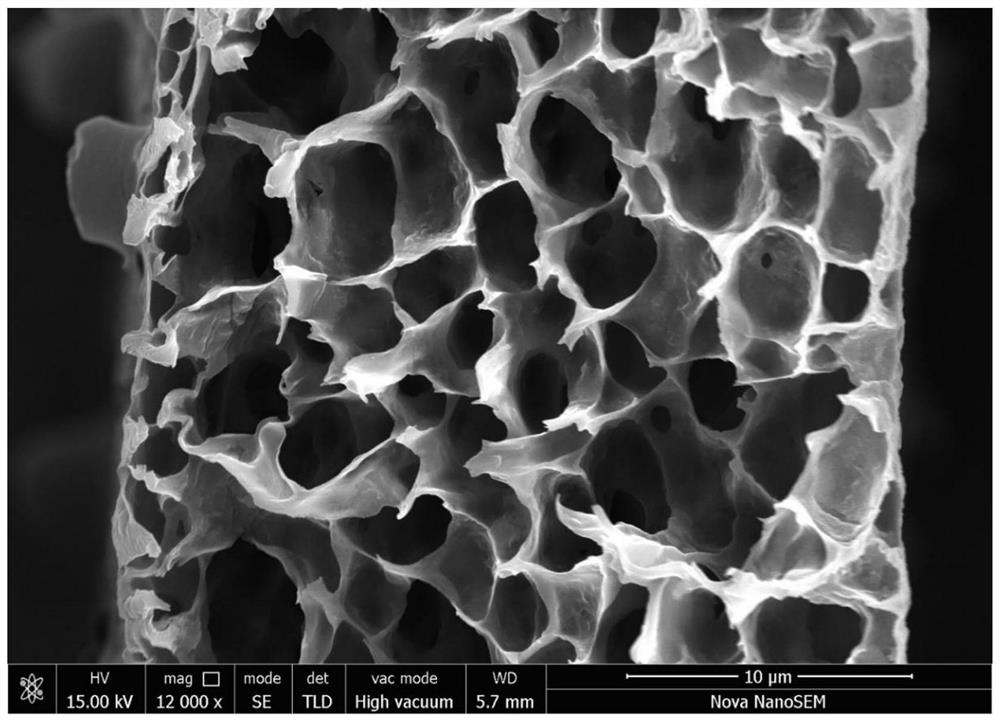

[0054] Dissolve the soluble polyether ether ketone precursor—polyether ether ketone-1,3-dioxolane (see literature [1, 2] for the preparation method) (1.0g) in the polar polymer good solvent NMP (4mL) , the mass concentration of the solution is 20%, and it is airtightly stirred at room temperature for 15 hours to prepare a clear and transparent casting solution; pour the casting solution on the surface of a horizontal glass plate, spread it evenly with a scraper, and then place it in a constant humidity box 10 minutes, and then made a polymer porous membrane; soak the obtained polymer porous membrane in deionized water for 50 hours, take it out and dry it at 80°C under vacuum, remove the residual polymer polar good solvent and place it in Soak in hydrochloric acid for 28 hours, take it out, rinse with deionized water, remove excess acid, and then dry it at 60°C under vacuum to obtain a polyetheretherketone porous membrane with adjustable pore size; the polyetheretherketone porou...

Embodiment 2

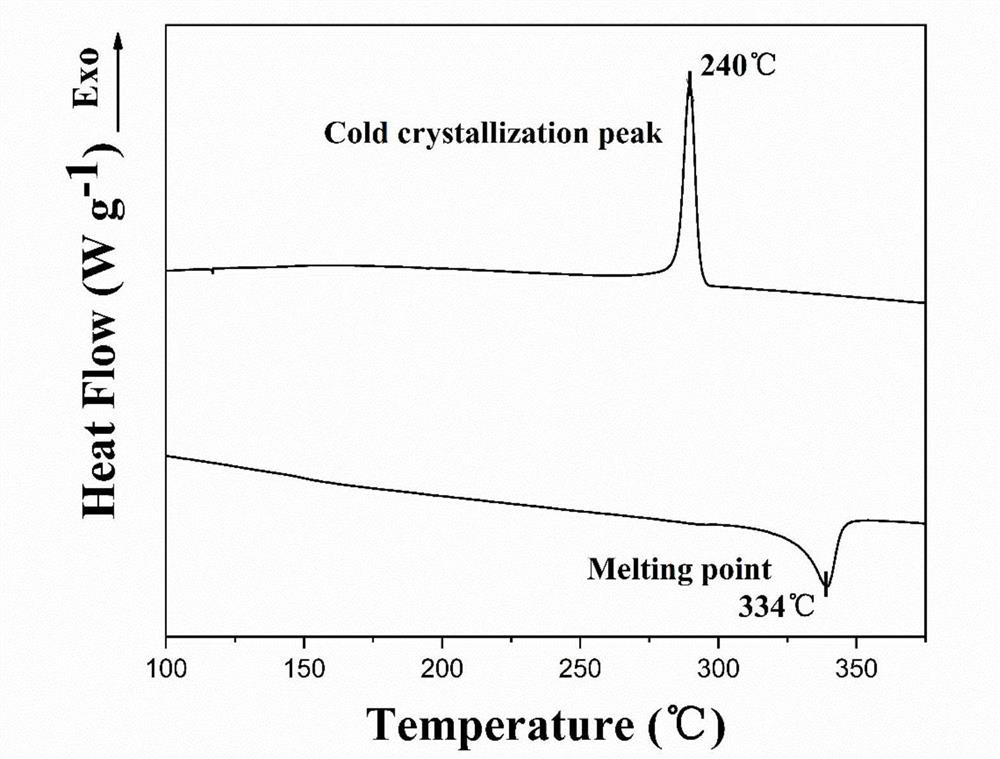

[0057] The preparation process of the crystalline polyetheretherketone porous membrane described in Example 1 is the same, and the DSC curve of the prepared crystalline polyaryletherketone porous membrane with adjustable pore size is similar to that of Example 1, and its crystallinity is 27%. , the pore diameter is 3 μm, the porosity is 80%, the pore morphology is sponge-like pores, and the thickness is 10 μm. Then, the prepared crystalline polyetheretherketone porous membrane was assembled into a supercapacitor according to the literature [4] for cyclic voltammetry curve test, using an electrochemical workstation (CHI 660A) in the voltage range of 0.0-3.0V, and the scan rate was 5mV s -1 , Tested at ambient temperature.

[0058] The linear sweep voltammetry curves of the supercapacitor conventional gel electrolyte (GPE-20) and cross-linked gel electrolyte (NGPE-CL-20) prepared in Example 2 are shown in the appendix Figure 8 ; The figure shows that both NGPE-CL-20 and GPE-2...

Embodiment 3

[0060] The same as in Example 1, except that the pore forming agent dibutyl phthalate (0.9g) was added to the casting solution, the ratio of its mass dosage to the polymer was 0.9:1, and the stirring was continued for 5 hours to make the pore forming agent Disperse evenly in the polymer solution; pour the casting solution with the porogen added on the surface of a horizontal glass plate, place it in an oven at 60°C, 80°C, and 100°C for 12 hours each, and then dry it in vacuum at 120°C for 12 hours. Solvent was completely removed. After taking out the membrane, place the membrane in a Soxhlet extractor, extract it with ethanol for 8 hours, and dry it in vacuum at 60°C for 12 hours to obtain a polymer porous membrane; soak the obtained polymer porous membrane in hydrochloric acid for 28 hours, take it out and use deionized Rinse with water to remove excess acid, then dry at 60°C under vacuum to obtain a polyether ether ketone porous membrane with adjustable pore size; heat-treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com