Manufacturing method for alloys with excellent durability performance under high temperature and high pressure conditions

A technology of high temperature and high pressure, manufacturing method, applied in strength characteristics, using stable tension/pressure to test material strength, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can only reach 35-45ppm, can only reach 5 -6ppm, reduction and other issues, to achieve the effect of low content of non-metallic inclusions, increase high temperature strength, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

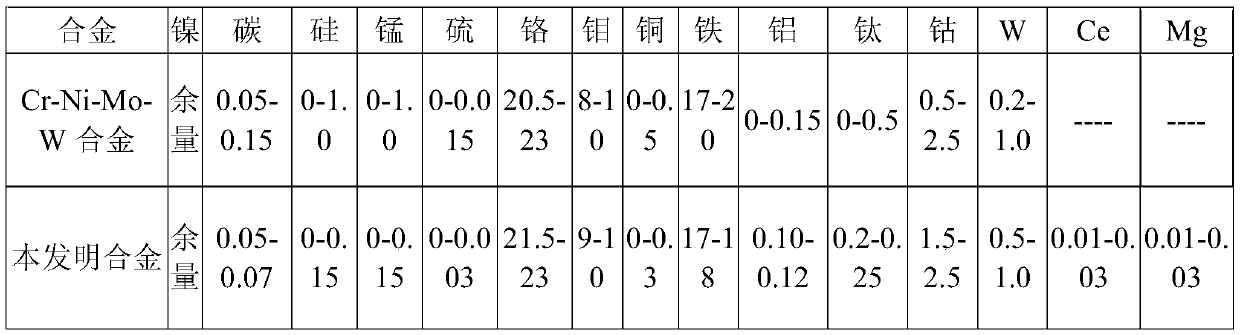

[0087] The basis for the compositional design of an alloy with excellent durability under high temperature and high pressure conditions according to the present invention is as follows:

[0088] Chromium, molybdenum, tungsten, niobium, cobalt and other alloying elements form a single-phase solid solution, which reduces the stacking fault energy and easily forms extended dislocations. longevity and lasting strength. The melting point of these elements is relatively high, the melting point of chromium is 1857°C, the melting point of molybdenum is 2620°C, the melting point of tungsten is 3410°C, the melting point of niobium is 2467°C, and the melting point of cobalt is 1495°C, which can especially improve the durability and strength of the alloy under high temperature conditions. .

[0089] The dispersed phase (precipitation of the second phase) in the Cr-Ni-Mo-W alloy can strongly hinder the slippage of dislocations, so it is another effective method to improve the high-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com