Aqueous epoxy fullerene heavy-duty anticorrosion coating and preparation method thereof

An epoxy fullerene, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, conductive coatings, etc., can solve the problems of restricted development, toxic storage, transportation and construction, flammable organic solvents, etc., to maintain anti-corrosion properties, improved corrosion resistance, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

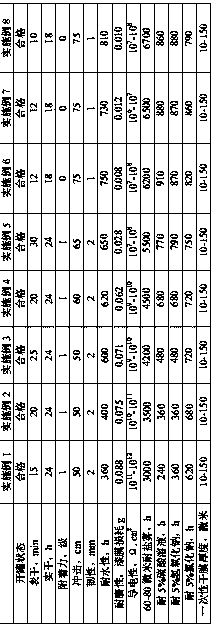

Examples

Embodiment 1

[0035]

[0036] Adopt above-mentioned raw material ratio, prepare by following method:

[0037] 1. Add the first water-based epoxy curing agent, dispersant, defoamer, corrosion inhibitor and co-solvent into the production tank, and stir for 5 minutes at 400-600 rpm;

[0038] 2. Add water-based organic bentonite, fumed silica, and water-based wax slurry while stirring, and stir for 5 minutes at 400-600 rpm;

[0039] 3. While stirring, add titanium dioxide, carbon black, precipitated barium sulfate, quartz powder, and water-based zinc phosphate, and stir at 600-800 rpm for 10 minutes.

[0040] 4. Use a sand mill to grind the fineness to 30 microns;

[0041] 5. Slowly add conductive mica powder while stirring at 400-600 rpm, and stir at 1000-1200 rpm for 25-30 minutes;

[0042] 6. Slowly add graphene slurry and fullerene slurry while stirring at 600-800 rpm, and stir at 800-1000 rpm for 40-60 minutes to obtain component A.

[0043] Component B uses water-based epoxy resin e...

Embodiment 2

[0045]

[0046] Adopt above-mentioned raw material ratio, prepare by following method:

[0047] 1. Add the first water-based epoxy curing agent, dispersant, defoamer, corrosion inhibitor and co-solvent into the production tank, and stir for 5 minutes at 400-600 rpm;

[0048] 2. Add water-based organic bentonite, fumed silica, and water-based wax slurry while stirring, and stir for 5 minutes at 400-600 rpm;

[0049] 3. While stirring, add titanium dioxide, carbon black, precipitated barium sulfate, quartz powder, and water-based zinc phosphate, and stir at 600-800 rpm for 10 minutes.

[0050] 4. Use a sand mill to grind the fineness to 30 microns;

[0051] 5. Slowly add conductive mica powder while stirring at 400-600 rpm, and stir at 1000-1200 rpm for 25-30 minutes;

[0052] 6. Slowly add graphene slurry and fullerene slurry while stirring at 600-800 rpm, and stir at 800-1000 rpm for 40-60 minutes to obtain component A.

[0053] Component B uses water-based epoxy resin e...

Embodiment 3

[0055]

[0056] Adopt above-mentioned raw material ratio, prepare by following method:

[0057] 1. Add the first water-based epoxy curing agent, dispersant, defoamer, corrosion inhibitor and co-solvent into the production tank, and stir for 5 minutes at 400-600 rpm;

[0058] 2. Add water-based organic bentonite, fumed silica, and water-based wax slurry while stirring, and stir for 5 minutes at 400-600 rpm;

[0059] 3. While stirring, add titanium dioxide, carbon black, precipitated barium sulfate, quartz powder, and water-based zinc phosphate, and stir at 600-800 rpm for 10 minutes.

[0060] 4. Use a sand mill to grind the fineness to 30 microns;

[0061] 5. Slowly add conductive mica powder while stirring at 400-600 rpm, and stir at 1000-1200 rpm for 25-30 minutes;

[0062] 6. Slowly add graphene slurry and fullerene slurry while stirring at 600-800 rpm, and stir at 800-1000 rpm for 40-60 minutes to obtain component A.

[0063] Component B uses water-based epoxy resin e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com