Conductive metal oxide current collector coating for aluminium ion battery

An aluminum ion battery, current collector coating technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as high cost and instability, reduce production and use costs, and achieve good corrosion resistance. , the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

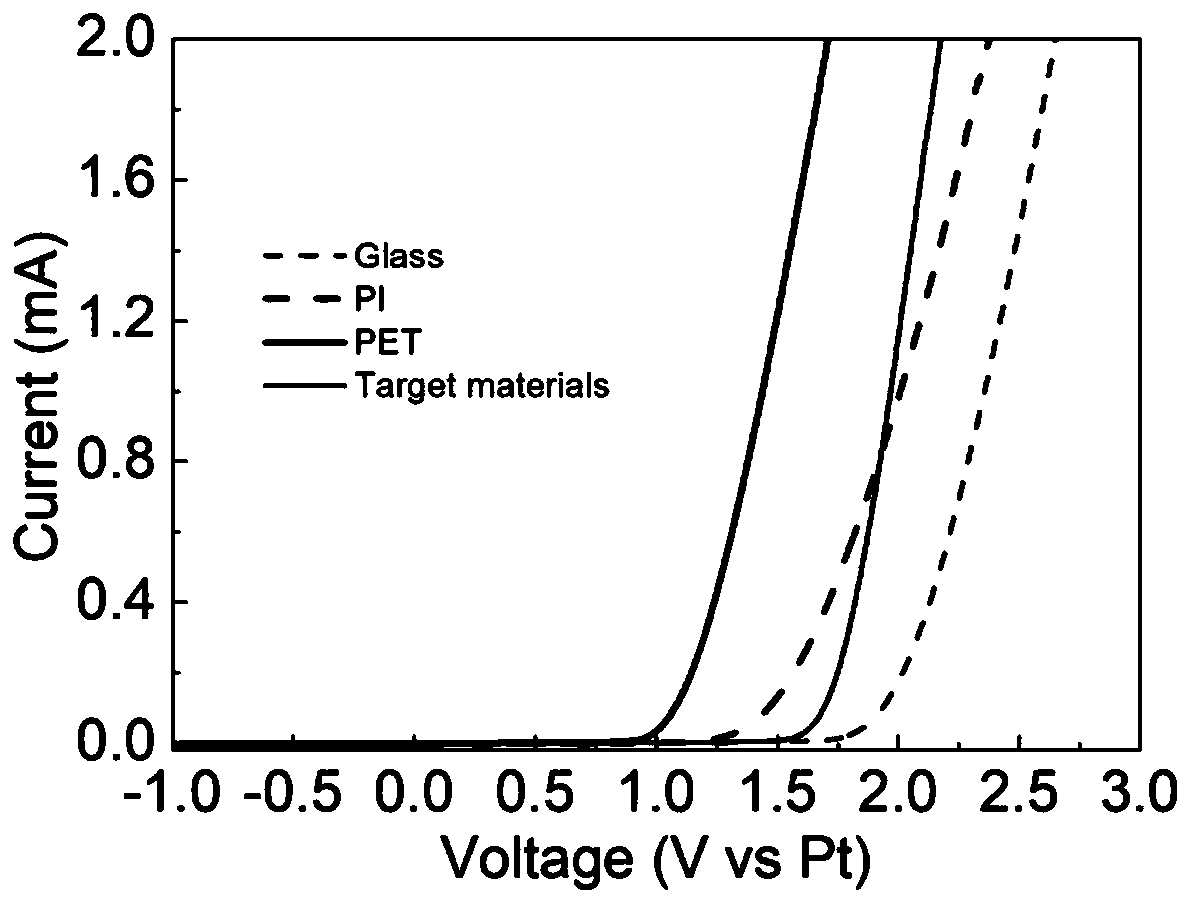

[0029] In this embodiment, the preliminary verification of the current collector anti-corrosion coating of the aluminum ion battery can be carried out by the following method: the purchased pure indium tin oxide target is wire-cut into pieces with a size of 10mm*3mm for electrochemical testing;

[0030] Clean the surface of the cut pure indium tin oxide target sheet ultrasonically for 5 minutes; select the prepared pure indium tin oxide target sheet as the working electrode, the metal aluminum sheet as the counter electrode, and the metal platinum sheet as the reference electrode for electrochemical three-electrode test.

[0031] The test steps include:

[0032] 1) Preparation of the imidazole system electrolyte for aluminum ion batteries. The aluminum ion-containing non-aqueous ionic electrolyte required for the configuration system, the material was dried in a vacuum oven before the preparation, and moved to the glove box, with AlCl 3 : [EMIm]Cl=1.3 (molar ratio) mixed in ...

Embodiment 2

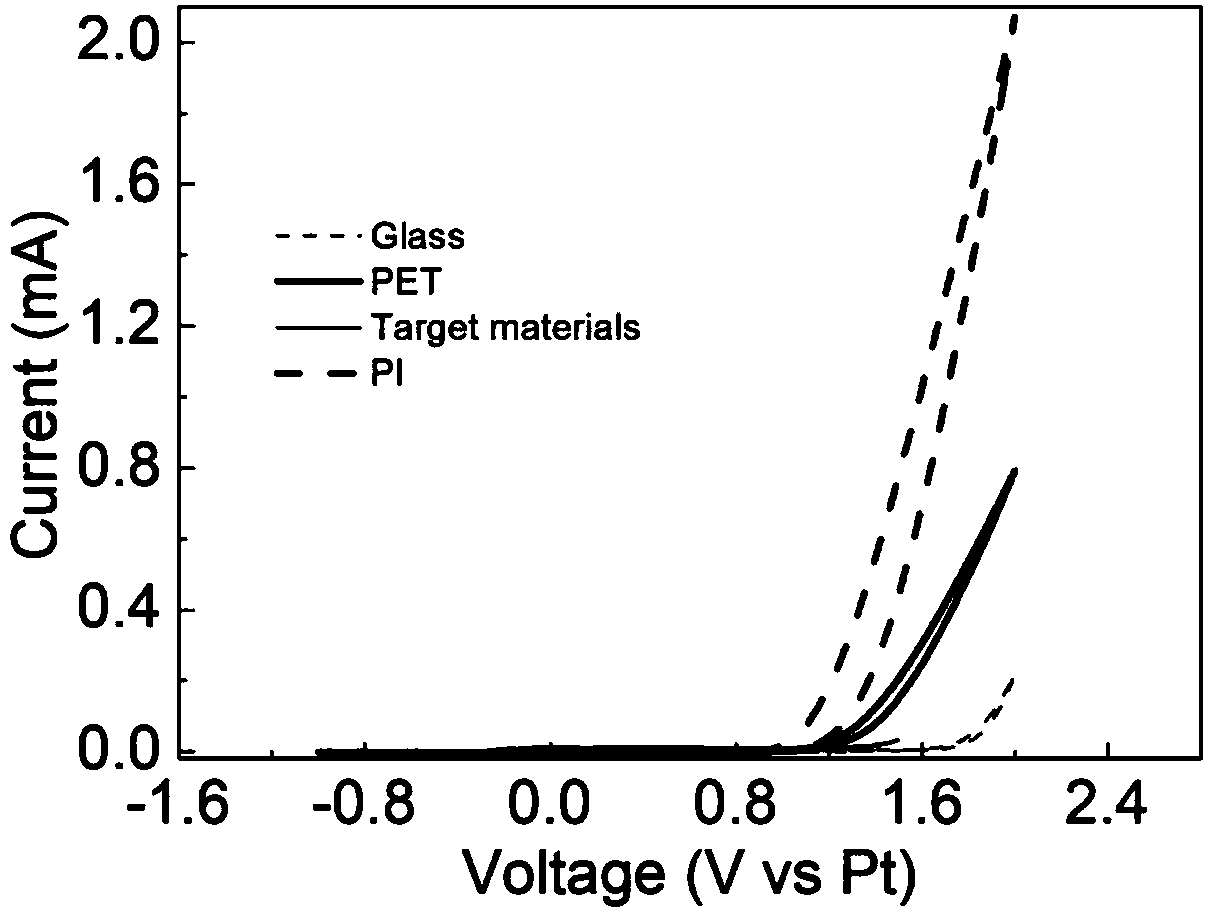

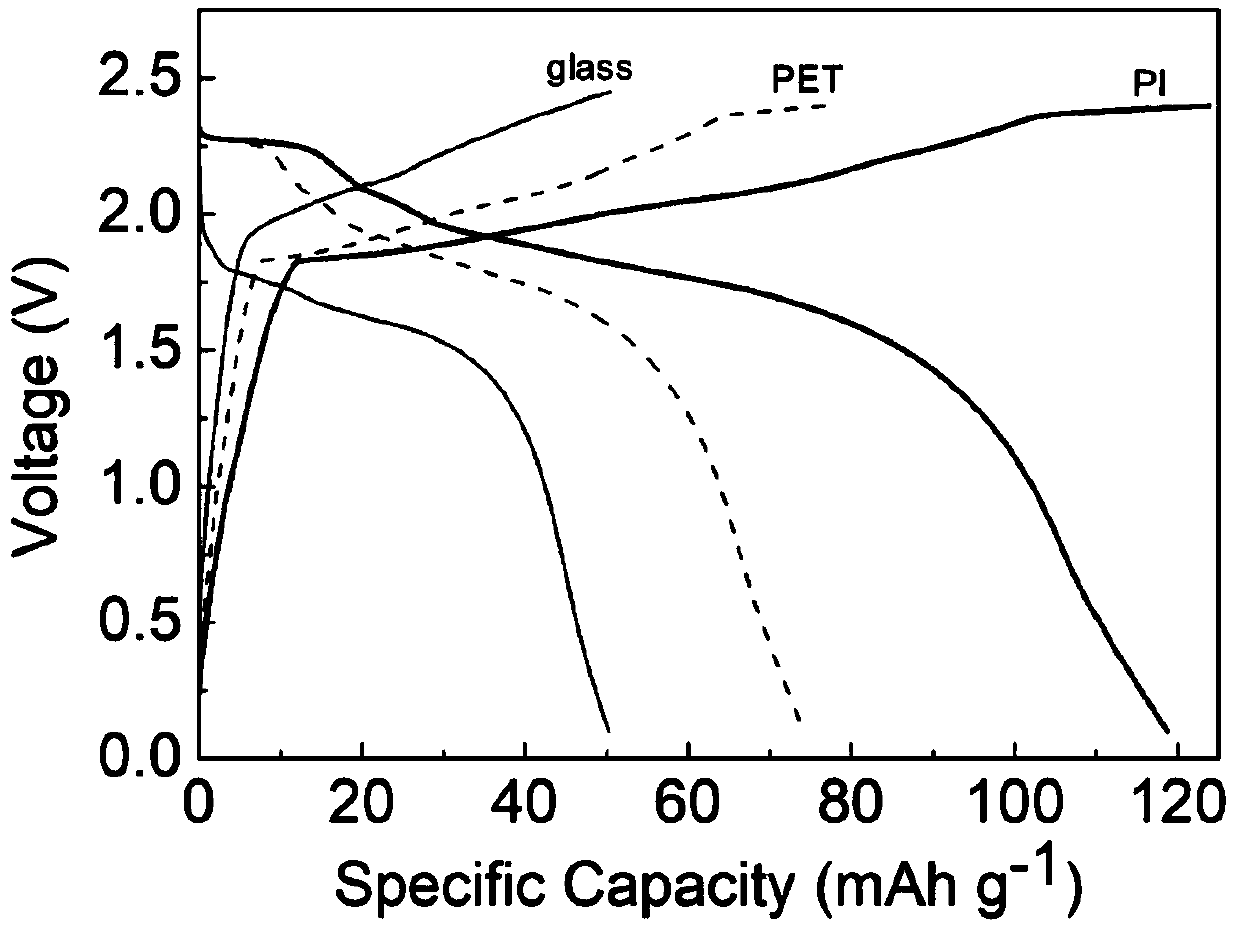

[0038] The preparation method of the aluminum ion battery current collector of the present embodiment is as follows: 1) select transparent glass with a thickness of 0.5mm as the current collector substrate, and ultrasonically clean it for 10 minutes; Sputtering chamber; 3) Set sputtering parameters: substrate temperature is room temperature, power 70w, DC sputtering, air pressure 3mtorr, sputtering time on one side is 70+-10min; 4) After sputtering, sampling, sputtering thickness 350nm+-10nm; 5) Take out the sputtered sample and cut it into a fixed size (5*10mm) for use.

[0039] Clean the surface of the cut glass sputtered with indium tin oxide coating, and wipe it with alcohol cotton; select the sputtered indium tin oxide current collector on the prepared glass substrate as the working electrode, the metal aluminum sheet as the counter electrode, and the metal platinum sheet as the reference electrode. Electrochemical three-electrode tests were performed with specific electr...

Embodiment 3

[0047] The preparation method of the aluminum ion battery current collector of the present embodiment is as follows: 1) select a polyethylene terephthalate polymer film with a thickness of 0.025 mm as the current collector substrate; 2) make polyethylene terephthalate Move the ester polymer film substrate to the magnetron sputtering chamber; 3) Set the sputtering parameters: the substrate temperature is room temperature, the power is 70w, DC sputtering, the air pressure is 3mtorr, and the sputtering time on one side is 70+-10min; 4 ) Sampling after sputtering, the sputtering thickness is 350nm+-10nm; 5) Take out the sputtered sample and cut it into the required size (5*10mm) for use.

[0048] Clean the surface of the cut and sputtered polyethylene terephthalate polymer film coated with indium tin oxide, and wipe it with alcohol cotton; select the prepared polyethylene terephthalate polymer film substrate to sputter Indium tin oxide current collector is used as working electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com