Charcoal-containing alumina support and preparation method therefor

A technology of alumina carrier and nitrogen compound, applied in catalyst carrier, chemical instrument and method, chemical/physical process, etc., can solve the problems of small pore volume, unsuitable for hydrotreating catalyst carrier, etc., achieve uniform crystal phase, improve Pore structure, favorable effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

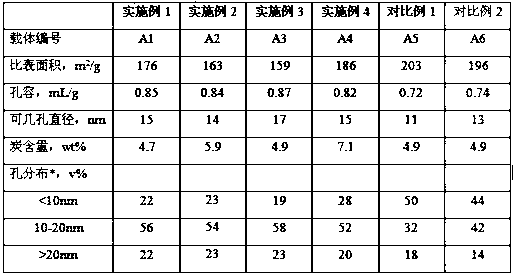

Embodiment 1

[0033] Weigh 200g of pseudoboehmite dry rubber powder (produced by Wenzhou Jingjing Alumina Co., Ltd., with an alumina dry basis content of 70wt%) and place it in a round-bottomed flask, add 600 grams of deionized water to the flask for beating, and add to the above slurry Add an appropriate amount of mixed acid solution with a molar concentration of nitric acid of 3 mol / L and a molar concentration of acetic acid of 1 mol / L, control the pH value of the slurry to 3 and heat and reflux at 40°C for 3 hours. The above slurry was transferred into an autoclave, 14 g of urea was added to the mixed material, and the autoclave was sealed and heat treated at 140° C. for 6 hours. After cooling to room temperature, the mixed slurry was filtered, washed, and dried at 120° C. for 8 hours to obtain treated pseudo-boehmite.

[0034]Weigh 135 grams of the above-mentioned treated pseudo-boehmite and mix them with 4 grams of carbon black powder evenly, add an appropriate amount of aqueous soluti...

Embodiment 2

[0038] With embodiment 1, just the add-on of deionized water is 1400 grams. In the mixed acid solution, the molar concentration of sulfuric acid is 4mol / L, the molar concentration of oxalic acid is 1mol / L, the pH value of the slurry is controlled to be 2, the temperature of heating and reflux is 30°C, and reflux is performed for 5 hours. The addition amount of urea is 21 grams, and hydrothermal treatment temperature is 120 ℃, and hydrothermal treatment is 8 hours. Xylitol is changed into glucose, and the consumption of solution is 30ml, and the concentration of glucose solution is 50wt%, and output power is 700W during microwave treatment, and processing time is 100s, makes carbon-containing macroporous alumina carrier A2 of the present invention, and the property of carrier sees Table 1.

Embodiment 3

[0040] With embodiment 1, just add 1.0 gram sodium tetraborates in the mixed material while adding urea. The charcoal-containing macroporous alumina carrier A3 of the present invention was obtained, and the properties of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com