Electrochemical sensor for monitoring nitrogen content, and manufacturing method for sensor

An electrochemical and sensor technology, applied in the field of electrochemical sensors for monitoring nitrogen content and its preparation, can solve the problems of poor compatibility, mutual repulsion, single phase number of compounds, etc., achieve small interface internal resistance, precise control of thickness, and good The effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

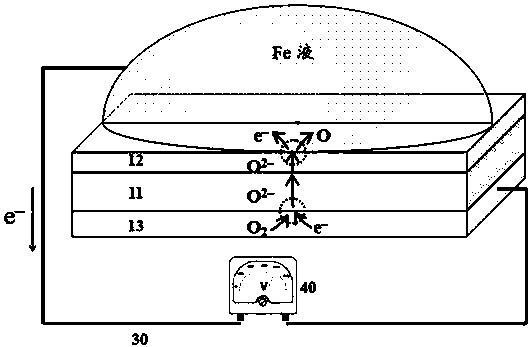

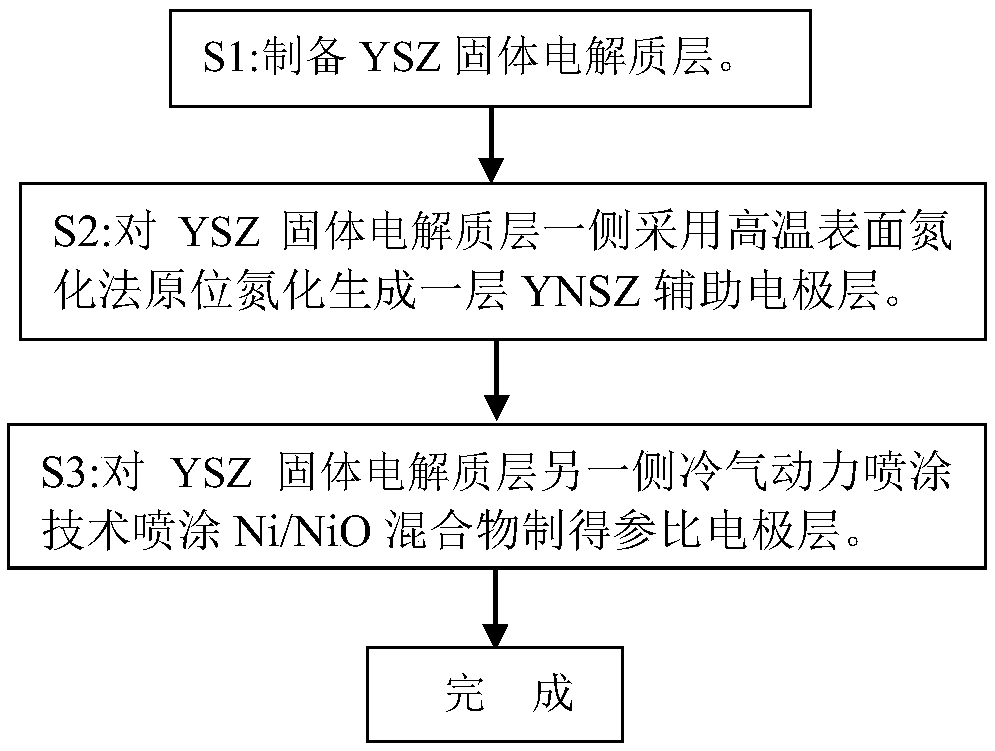

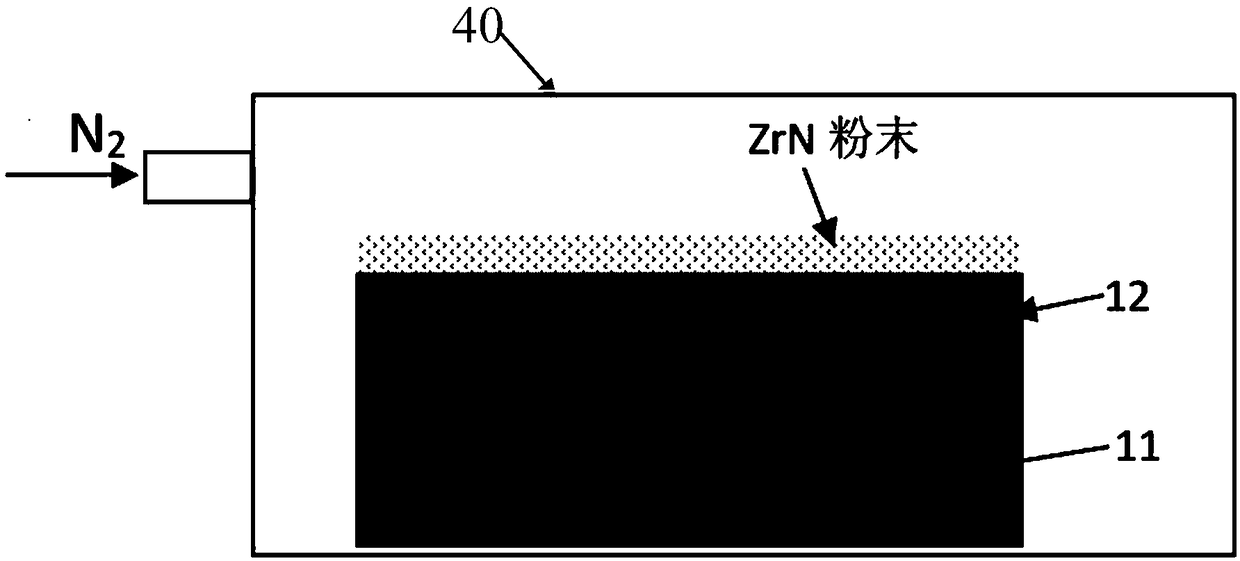

[0048] see figure 2 Shown is a flow chart of the preparation method of an electrochemical sensor for monitoring nitrogen content of the present invention. It basically includes steps: S1: preparation of YSZ solid electrolyte layer; S2: high-temperature surface nitriding treatment: use high-temperature surface nitriding method to make one side surface of the YSZ solid electrolyte layer contact with metal nitride powder, bake at high temperature and nitrogen Under the protection of the atmosphere, the side surface of the YSZ solid electrolyte layer is nitrided, and a layer of nitrogen ion and oxygen ion co-doped zirconia layer (YNSZ Auxiliary electrode layer); S3: Coating NiO and Ni mixed powder on the surface of the other side of the YSZ solid electrolyte layer to prepare a reference electrode layer. Preferably, step S3 is to use cold air power spraying technology to spray NiO and Ni mixed powder onto the surface of the YSZ solid electrolyte layer, the bonding strength is hig...

Embodiment 1

[0075] Step 1. Prepare YSZ solid electrolyte powder: weigh 7.82g YCl 3 , 148.24 g ZrOCl 2 ·8H 2 O, dissolved in 1 L of deionized water to give Zr 4+ The concentration is about 0.46mol / L. Stir with a magnetic stirrer, keep the temperature at 25°C, add ammonia water dropwise for co-precipitation, stop the titration when the pH is 9-10, filter the precipitate, wash with distilled water and ethanol three times respectively, and remove Cl - and other impurity ions. Dry the precipitate at a temperature of 75-85°C, dry at a constant temperature for 24 hours, grind it in an agate mortar for 0.5 hours, and then roast it in a high-temperature furnace for 10 hours at a temperature of 600°C to obtain Y 2 o 3 Stable zirconia solid electrolyte powder YSZ.

[0076] Step 2. Making the YSZ solid electrolyte layer: Weigh 30g of solid YSZ powder into a 5cm-diameter die, apply 300Mpa axial pressure to press into a sheet-shaped green body, and place it in a high-temperature furnace for sinteri...

Embodiment 2

[0080] The difference between this embodiment and embodiment 1 is that in step 3, the heating temperature in the furnace 40 is controlled to 1600° C. for 8 hours to obtain a YNSZ auxiliary electrode layer 12 with a thickness of 0.8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com